Method for preparing low-carbon olefins through co-catalytic cracking of Fischer-Tropsch synthesis light oil and methyl alcohol

A technology of Fischer-Tropsch synthesis and catalytic cracking, which is applied in the direction of hydrocarbon cracking to produce hydrocarbons, carbon compound catalysts, chemical instruments and methods, etc. It can solve the problems of low selective yield of low-carbon olefins, economics, and industrial implementation and gaps. , to achieve the effect of efficiently obtaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

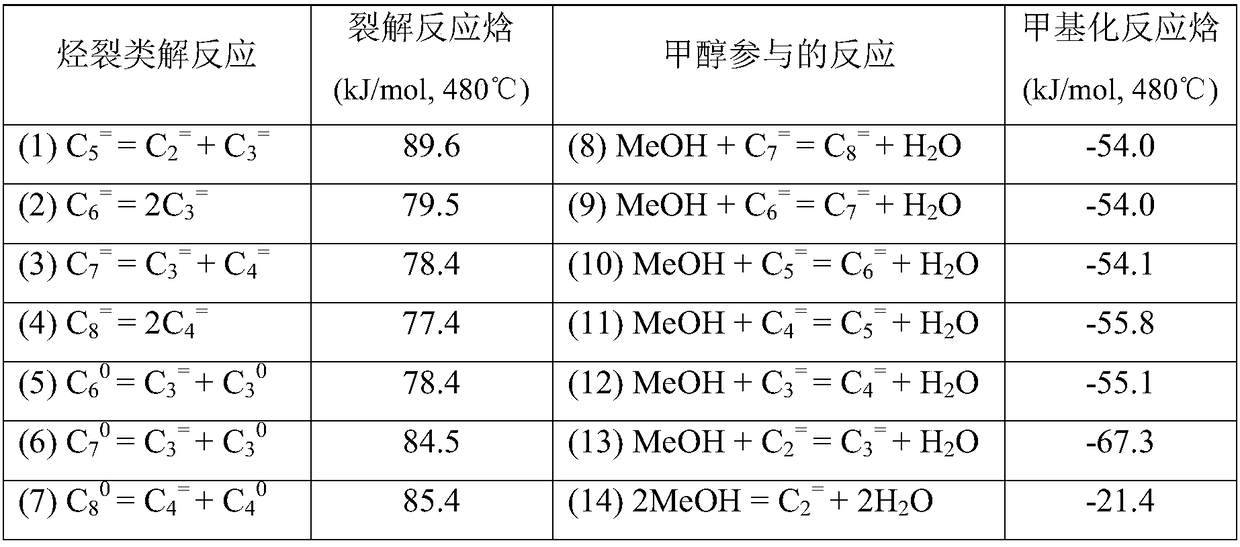

Method used

Image

Examples

Embodiment 1

[0033] This example considers the C in the distillate oil 6 Higher olefin model compound 1-hexene and methanol co-catalyzed cracking reaction. The catalyst is a commercially modified ZSM-5 molecular sieve catalyst (from Nankai Catalyst Factory), with a particle size of 0.28-0.45 mm (corresponding to 40-60 mesh). The catalytic cracking process uses The quartz glass tubular micro-fixed bed reactor adopts electric heating PID temperature control, and the temperature control accuracy is ±0.5°C.

[0034] First mix 0.25g of modified ZSM-5 molecular sieve catalyst (ZSM-5 molecular sieve content is 30wt%) with 1.75g of quartz sand (as a packed bed inert filler) and then load it into the constant temperature section of the reactor, and then fill the catalyst with quartz wool And quartz sand, a thermocouple is inserted into the bed to measure the temperature.

[0035] The catalytic cracking process adopts mixed feeding of hexene and methanol aqueous solution, the concentration o...

Embodiment 2

[0046] This example considers the C in the distillate oil 7 Higher olefin model compound 1-heptene and methanol co-catalyzed cracking reaction. The modified ZSM-5 molecular sieve catalyst is adopted, and the loading amount of the fixed-bed catalyst is also consistent with that of Example 1, which is 0.25 g.

[0047] 1-heptene and methanol aqueous solution are used as mixed feed, the concentration of methanol in the methanol aqueous solution is 16.0 wt%, and 1-heptene is an analytically pure raw material. Liquid phase raw material 1-heptene and aqueous methanol solution are metered with high-pressure constant-flow pump respectively, and 1-heptene feed mass flow rate is 11.76g / hour, and 16.0wt% methanol aqueous solution feed mass flow rate is 12.0g / hour (feeding high The molar ratio of carbon olefins to methanol is 2.0), and at the same time, 3.0L / hour of high-purity nitrogen is introduced as a diluent gas. The catalytic cracking temperature is 500°C.

[0048] One hour afte...

Embodiment 3

[0050] This example considers C 8 Cocatalyzed Cracking Reaction of Higher Olefin 1-Octene and Methanol. The conditions of the modified ZSM-5 molecular sieve catalyst used and the loading amount of the catalyst were the same as in Example 1, and the catalytic cracking reaction temperature was 490°C. 1-heptene and methanol aqueous solution are used as mixed feed, the concentration of methanol in the methanol aqueous solution is 16.0 wt%, and 1-octene is an analytically pure raw material.

[0051] Liquid phase raw material 1-octene and aqueous methanol solution are metered with high-pressure constant-flow pump respectively, and 1-octene feed mass flow rate is 13.44g / hour, and 16.0wt% methanol aqueous solution feed mass flow rate is 12.0g / hour (feeding high The molar ratio of carbon olefins to methanol is 2.0), and at the same time, 3.0L / hour of high-purity nitrogen is introduced as a diluent gas.

[0052] One hour after the start of the reaction, the reaction product was samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com