Gas tank rubber sealing membrane sizing material composition and preparation method thereof

A technology of rubber sealing and composition, applied in the field of gas cabinet rubber sealing film sizing material composition and preparation thereof, can solve the problems of poor cold resistance, poor weather resistance of products, etc., and achieves improved weather resistance and cold resistance, excellent Airtightness, effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

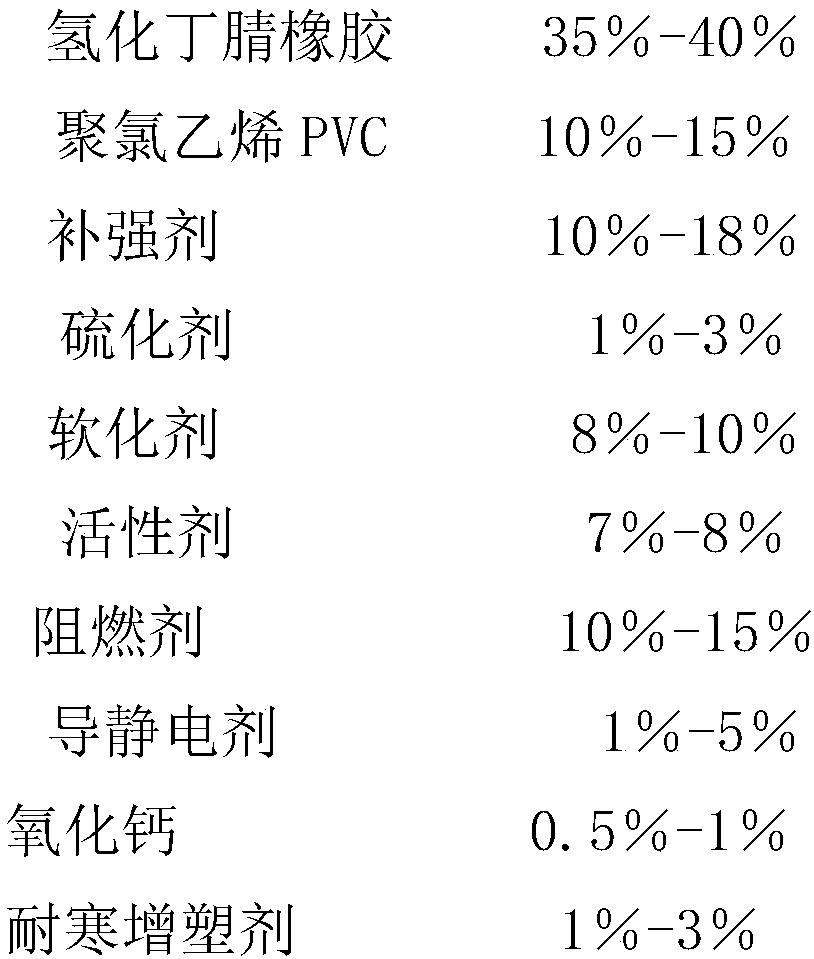

Method used

Image

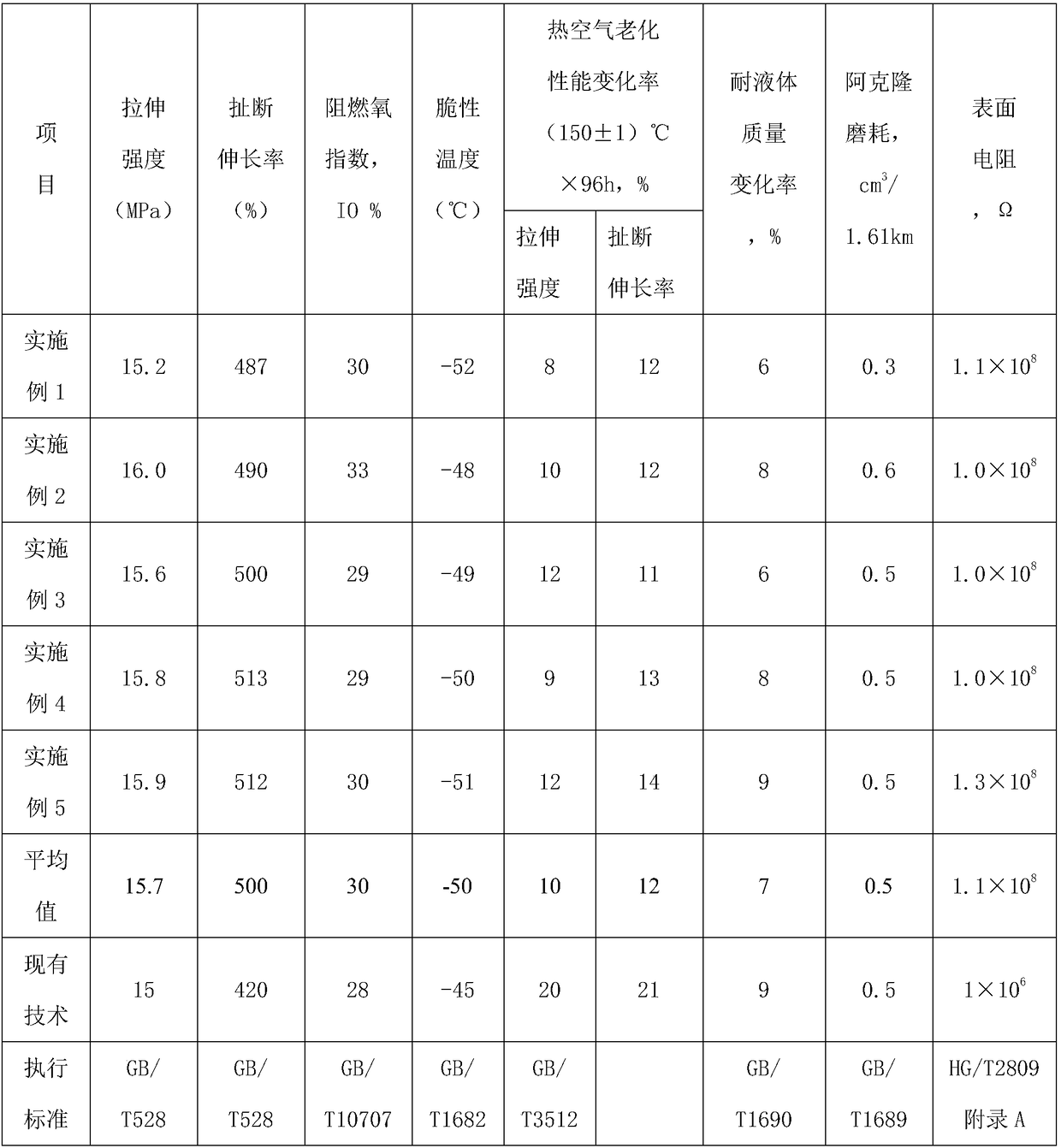

Examples

Embodiment 1

[0031] Plasticize the hydrogenated nitrile rubber according to the content of each component specified in Table 1 below to reach the specified plasticity; pre-swell the PVC for plasticizing and swelling treatment. The plasticized swelling treated PVC is blended with masticated hydrogenated nitrile rubber.

[0032] Add N550 carbon black, odorless DCP, dioctyl phthalate, zinc oxide, zinc borate, DOS, calcium oxide, UV-531 into the blend of hydrogenated nitrile rubber and PVC for conventional mixing.

Embodiment 2

[0034] Plasticize the hydrogenated nitrile rubber according to the content of each component specified in Table 1 below to reach the specified plasticity; pre-swell the PVC for plasticizing and swelling treatment. The plasticized swelling treated PVC is blended with masticated hydrogenated nitrile rubber.

[0035] Add N330 carbon black, odorless DCP, dioctyl phthalate, stearic acid, antimony trioxide, UV-531, DOS, and calcium oxide into the blend of hydrogenated nitrile rubber and PVC for conventional mixing.

Embodiment 3

[0037] Plasticize the hydrogenated nitrile rubber according to the content of each component specified in Table 1 below to reach the specified plasticity; pre-swell the PVC for plasticizing and swelling treatment. The plasticized swelling treated PVC is blended with masticated hydrogenated nitrile rubber.

[0038] Add white carbon black, odorless DCP, TOTM, stearic acid, aluminum hydroxide, DOS, UV-531, and calcium oxide into the blend of hydrogenated nitrile rubber and PVC for conventional mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com