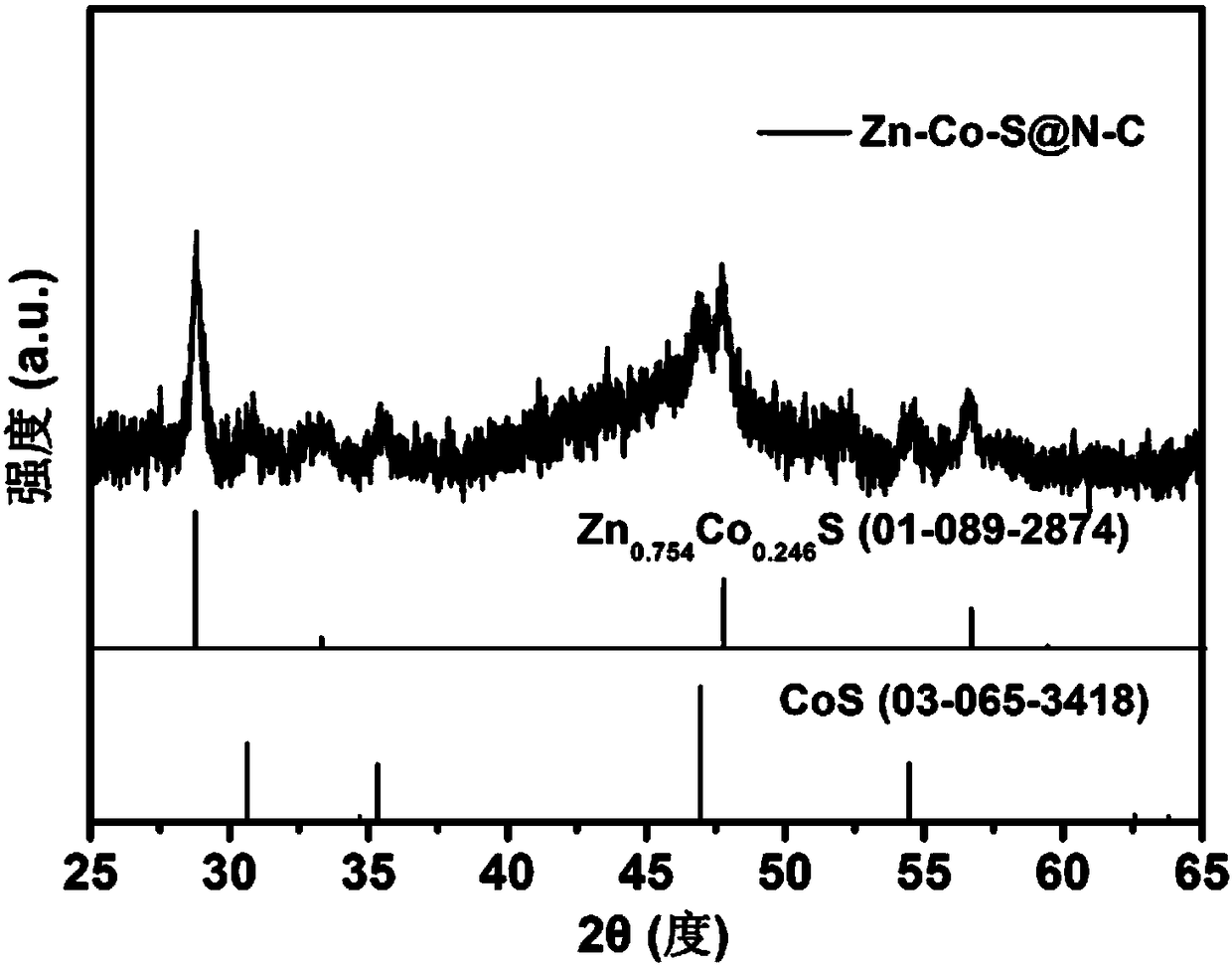

Zinc-cobalt sulfide/nitrogen-doped carbon composite material and preparation method and application thereof

A technology of nitrogen-doped carbon and composite materials, which is applied in the field of nanomaterials and electrochemistry, can solve the problems of capacity fading, low conductivity and ion diffusion rate, and achieve high power density, shorten diffusion distance, and buffer volume change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

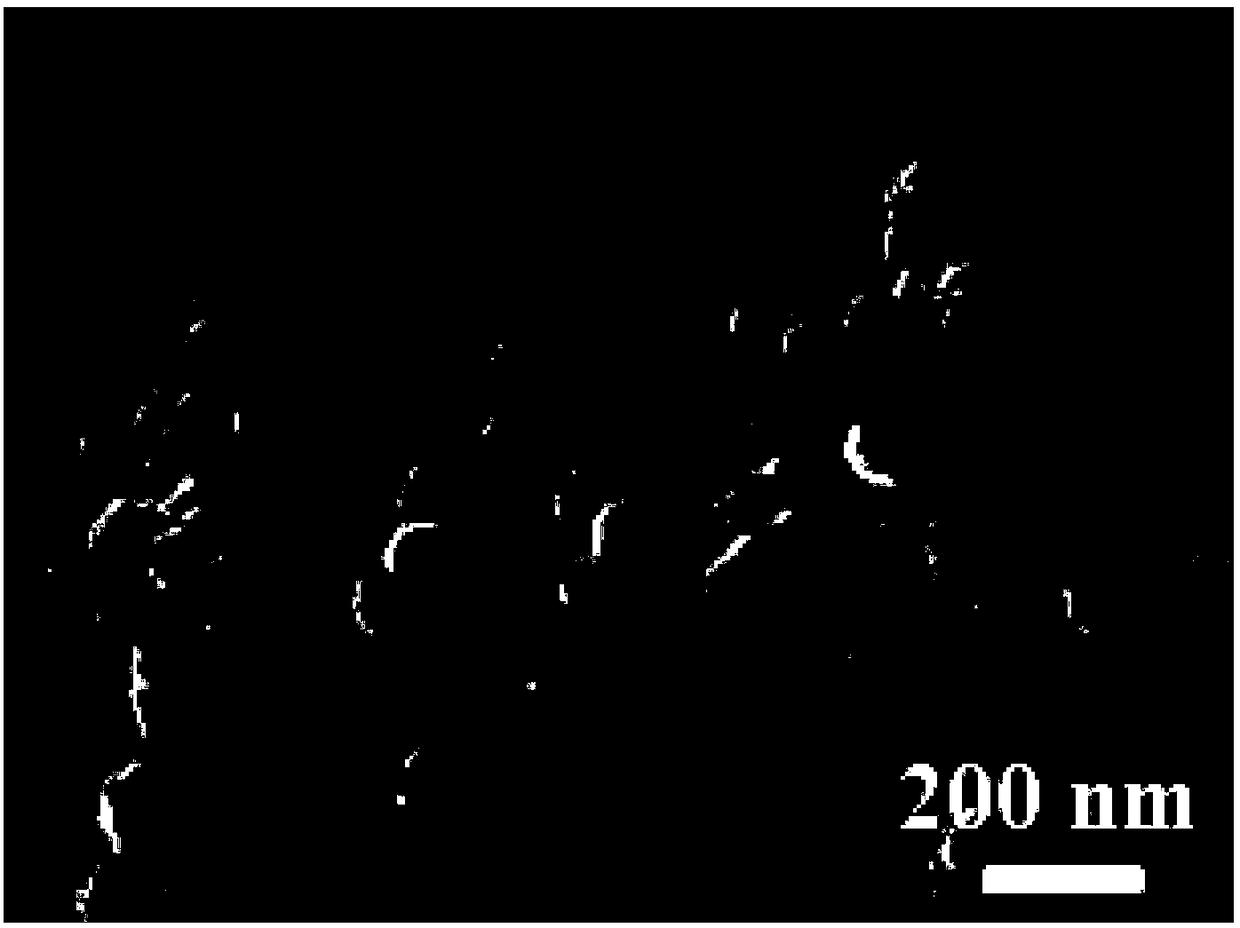

Embodiment 1

[0033] Embodiment 1: the preparation method of the zinc-cobalt sulfide / nitrogen-doped carbon composite material of egg yolk shell structure, it comprises the steps:

[0034] 1) Dissolve 1 mmol of zinc nitrate hexahydrate and 3 mmol of cobalt nitrate hexahydrate in 40 ml of methanol, and stir until completely dissolved;

[0035] 2) Dissolve 12mmol dimethylimidazole in 40ml methanol and stir until completely dissolved;

[0036] 3) Slowly add the solution obtained in step 1) dropwise to the solution obtained in step 2), and stir and react for 24 hours;

[0037] 4) The product obtained in step 3) was centrifuged, washed three times with absolute ethanol, and dried in an oven at 60-80°C to obtain a precursor;

[0038] 5) Dissolve 1 mmol tris in 100 ml of absolute ethanol and stir until completely dissolved;

[0039] 6) Add 80 mg of the precursor obtained in step 4) to the solution obtained in step 5), and stir until completely dissolved;

[0040] 7) Add 40 mg of dopamine hydroch...

Embodiment 2

[0047] 1) Dissolve 1 mmol of zinc nitrate hexahydrate and 4 mmol of cobalt nitrate hexahydrate in 50 ml of methanol, and stir until completely dissolved;

[0048] 2) Dissolve 12mmol dimethylimidazole in 40ml methanol and stir until completely dissolved;

[0049] 3) Slowly add the solution obtained in step 1) dropwise to the solution obtained in step 2), and stir and react for 25 hours;

[0050] 4) The product obtained in step 3) was centrifuged, washed three times with absolute ethanol, and dried in an oven at 60-80°C to obtain a precursor;

[0051] 5) Dissolve 1 mmol tris in 100 ml of absolute ethanol and stir until completely dissolved;

[0052] 6) Add 80 mg of the precursor obtained in step 4) to the solution obtained in step 5), and stir until completely dissolved;

[0053] 7) Add 40 mg of dopamine hydrochloride to the solution obtained in step 6), and stir and react for 3 hours;

[0054] 8) centrifuging the product obtained in step 7), washing with absolute ethanol for...

Embodiment 3

[0058] 1) Dissolve 2 mmol of zinc nitrate hexahydrate and 3 mmol of cobalt nitrate hexahydrate in 50 ml of methanol, and stir until completely dissolved;

[0059] 2) Dissolve 12mmol dimethylimidazole in 40ml methanol and stir until completely dissolved;

[0060] 3) Slowly add the solution obtained in step 1) dropwise to the solution obtained in step 2), and stir and react for 25 hours;

[0061] 4) The product obtained in step 3) was centrifuged, washed three times with absolute ethanol, and dried in an oven at 60-80°C to obtain a precursor;

[0062] 5) Dissolve 1 mmol tris in 100 ml of absolute ethanol and stir until completely dissolved;

[0063] 6) Add 80 mg of the precursor obtained in step 4) to the solution obtained in step 5), and stir until completely dissolved;

[0064] 7) Add 40 mg of dopamine hydrochloride to the solution obtained in step 6), and stir and react for 3 hours;

[0065] 8) centrifuging the product obtained in step 7), washing with absolute ethanol for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com