Modified acrylic ester external wall emulsion with high stain resistance and preparation method thereof

A technology of acrylate and butyl acrylate, which is applied in the field of modified acrylate high stain-resistant exterior wall emulsion and its preparation, which can solve the problems of poor performance, easy staining, and pulverization of exterior wall coatings, and achieve anti-oxidation performance Good, good adhesion, not easy to be oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

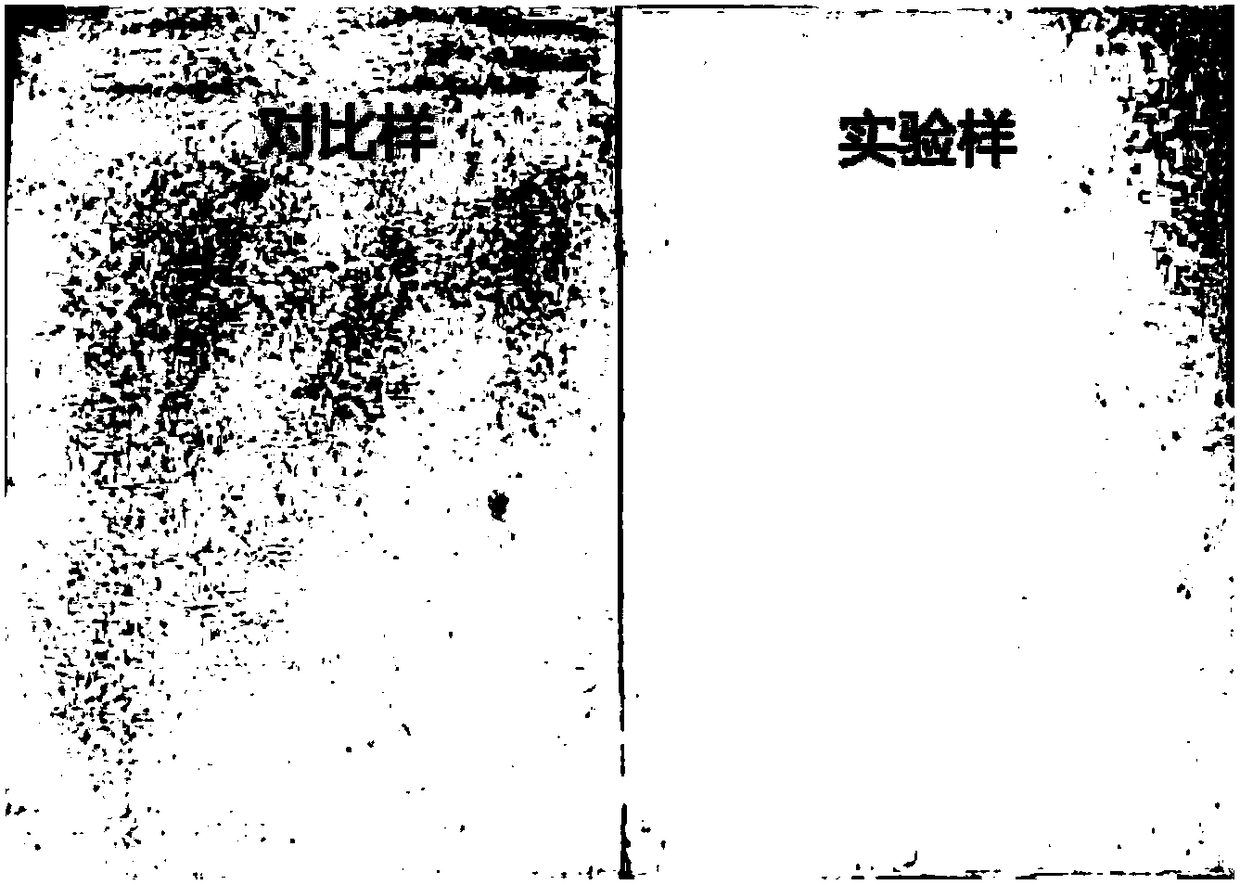

Image

Examples

preparation example Construction

[0032] A preparation method of the modified acrylate highly stain-resistant exterior wall emulsion, comprising the following steps:

[0033] 1) Under normal temperature and pressure, add polyethylene glycol and 0.02-0.5 parts of reactive emulsifier into the reaction kettle, heat up to 75-80°C, stir well, slowly drop in sodium silicate water glass, drop The time is 4-5h, the reaction temperature is 75-80°C, keep the temperature for 1h after dripping, then cool down to normal temperature, and get the modified water glass for later use;

[0034] 2) Under normal temperature and pressure, fully mix 15-30 parts of water, 0.02-0.5 parts of reactive emulsifier, and 0.05-1.5 parts of non-ionic emulsifier in the emulsification tank, and then add methyl methacrylate and butyl acrylate , methacrylic acid, and cross-linking monomers to make a pre-emulsion, stir for about 30 minutes, and set aside;

[0035] 3) Take 0.05-0.5 parts of ammonium persulfate and 0.5-1.5 parts of water to make a ...

Embodiment 1

[0041] A modified acrylate highly stain-resistant exterior wall emulsion, comprising the following raw materials in parts by weight: 30 parts of water, 50 parts of methyl methacrylate, 30 parts of butyl acrylate, 0.1 part of methacrylic acid, cross-linking monomer 0.1 part of body, 0.1 part of ammonium persulfate, 0.1 part of sodium bicarbonate, 0.1 part of reactive emulsifier, 0.1 part of nonionic emulsifier, 15 parts of polyethylene glycol, 20 parts of sodium silicate water glass, and 3 parts of ammonia water.

[0042] The crosslinking monomer is allyl methacrylate.

[0043] The reactive emulsifier is sodium 3-allyloxy-1-hydroxyl-1-propanesulfonate.

[0044] The nonionic emulsifier is alkyl polyoxyethylene ether LCN407.

[0045] The polyethylene glycol is PEG200.

[0046] The modulus of the sodium silicate water glass is between 3.5-4.5.

[0047] A preparation method of the modified acrylate highly stain-resistant exterior wall emulsion, comprising the following steps:

...

Embodiment 2

[0062] A modified acrylate highly stain-resistant exterior wall emulsion, comprising the following raw materials in parts by weight: 35 parts of water, 55 parts of methyl methacrylate, 35 parts of butyl acrylate, 1.5 parts of methacrylic acid, cross-linking monomer 2 parts of body, 1 part of ammonium persulfate, 0.3 parts of sodium bicarbonate, 1.5 parts of reactive emulsifier, 2 parts of nonionic emulsifier, 20 parts of polyethylene glycol, 25 parts of sodium silicate water glass, and 4 parts of ammonia water.

[0063] The crosslinking monomer is vinyltrimethoxysilane. The reactive emulsifier is sodium vinylsulfonate.

[0064] The nonionic emulsifier is alkyl polyoxyethylene ether LCN287. The polyethylene glycol is PEG200.

[0065] The modulus of the sodium silicate water glass is between 3.5-4.5.

[0066] A preparation method of the modified acrylate highly stain-resistant exterior wall emulsion, comprising the following steps:

[0067] 1) Under normal temperature and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com