Short-process dyeing and finishing process for polyamide viscose fabric

A nylon-bond fabric, short-process technology, applied in the field of textile dyeing and finishing, can solve the problems of different color of nylon-cotton fibers, complex process flow, high energy consumption, etc., to reduce fiber damage, improve production efficiency, and shorten dyeing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of antibacterial functional finishing agent is:

[0048] Add 120mL of acetone, 12 parts of nano-zinc oxide, 3 parts of KH-570γ-methacryloxypropyltrimethoxysilane into the stirred tank, stir and react at 40°C for 24 hours, centrifuge the mixture, and wash it twice with methanol , and dried at 70°C to obtain surface-modified nano-zinc oxide for subsequent use;

[0049] Weigh 8 parts of methyl methacrylate, 26 parts of butyl acrylate, and 4 parts of acrylic acid, stir and mix to form a monomer mixture;

[0050] Another 0.5 part of potassium persulfate was dissolved in 20 parts of water to make an aqueous initiator solution;

[0051]146 parts of water, 5 parts of surface-modified nano-zinc oxide, 11 parts of acryloyloxyethyl-propyltrimethoxysilane-dimethylammonium chloride, 3 parts of dodecyldimethylbenzyl chloride Ammonium, 2 parts of dioctadecyl dimethyl ammonium chloride, 3 parts of AEO-9 were placed in the reaction kettle, stirred and heated to ...

Embodiment 2

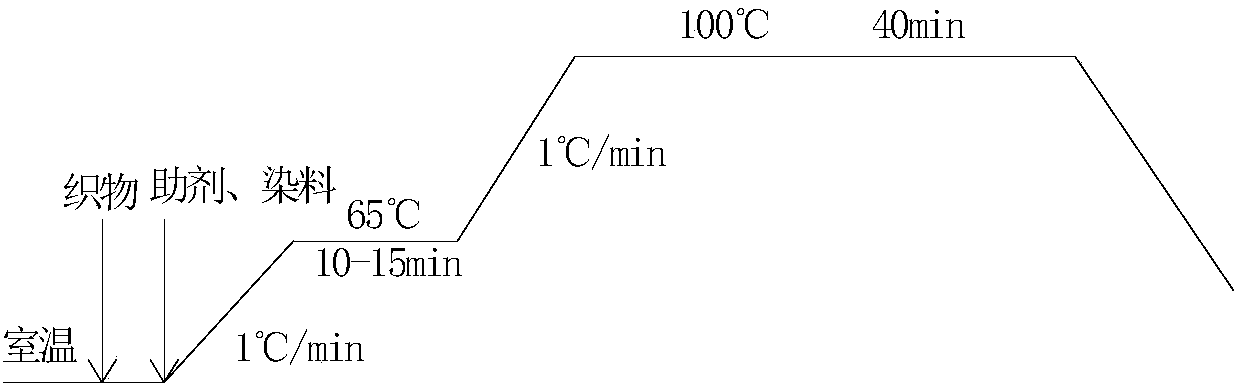

[0056] The short-process dyeing and finishing process of brocade sticky fabrics includes the following steps:

[0057] (1), pre-processing

[0058] (1) Squeeze liquid to stand still

[0059] Technological process: two dipping and two rolling (over 100% rolling rate) → open width coil → stacking

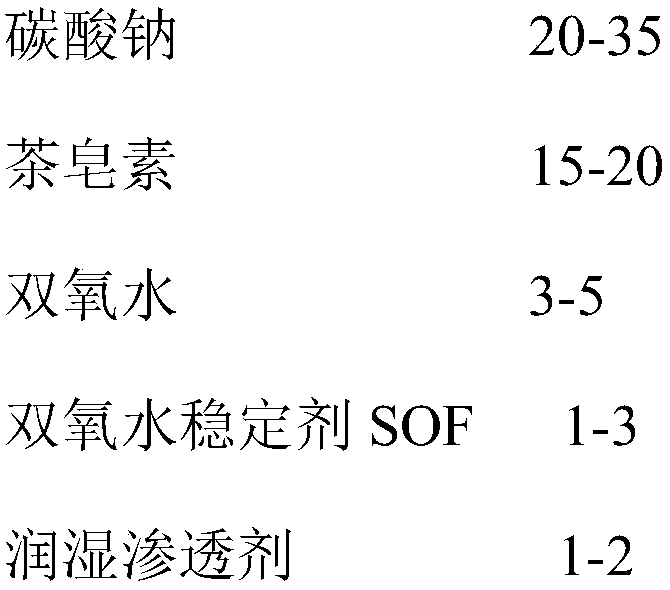

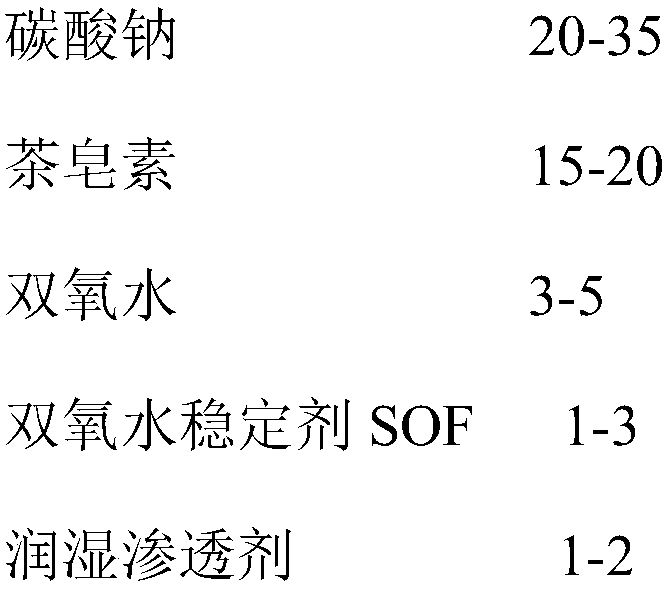

[0060] Process prescription (g / L):

[0061]

[0062] Wrap tightly with plastic film to prevent air drying, resulting in uneven desizing, and rotate and stack at room temperature for 12 hours;

[0063] (2) Efficient open width washing

[0064] Wash the stacked Nylon fabric with open-width washing machine to wash off various sizing, additives and contaminated impurities on the gray fabric; completely remove the spinning oil added during the spinning process of nylon to prevent Cloud spots will appear during dyeing, the temperature of the water tank is: 90°C, 90°C, 95°C, 90°C, 85°C, 80°C;

[0065] (2), Pre-type

[0066] 180~190℃, time 30s, speed 40~45m / min;

[0067] (three), dy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com