Black absorbent coating, solar-thermal conversion component with coating and solar water heater

An absorbing coating and light-to-heat conversion technology, which is applied in solar thermal power generation, radiation-absorbing coatings, coatings, etc., to achieve the effects of increasing light-to-heat conversion efficiency, good salt spray resistance, and high light-to-heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

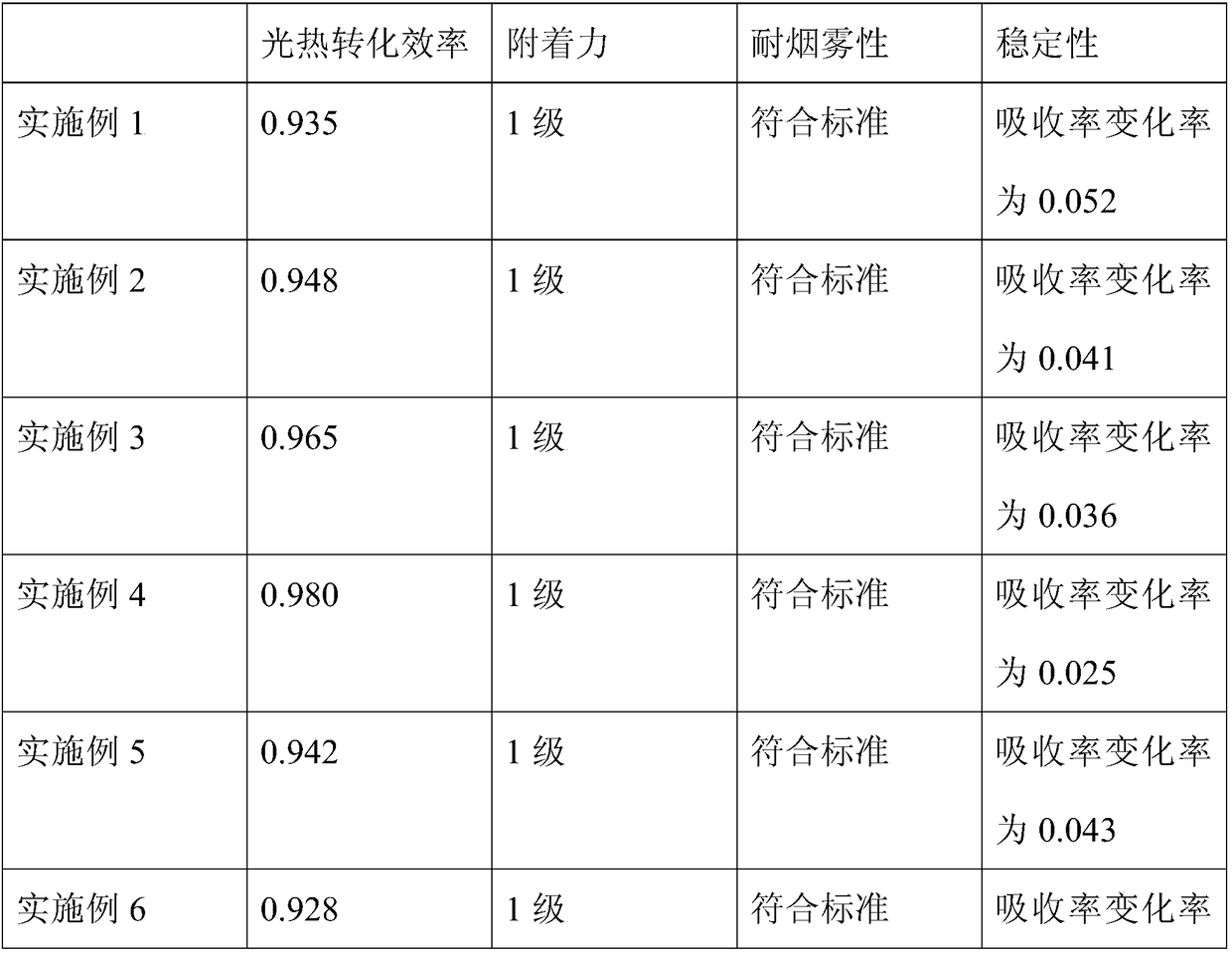

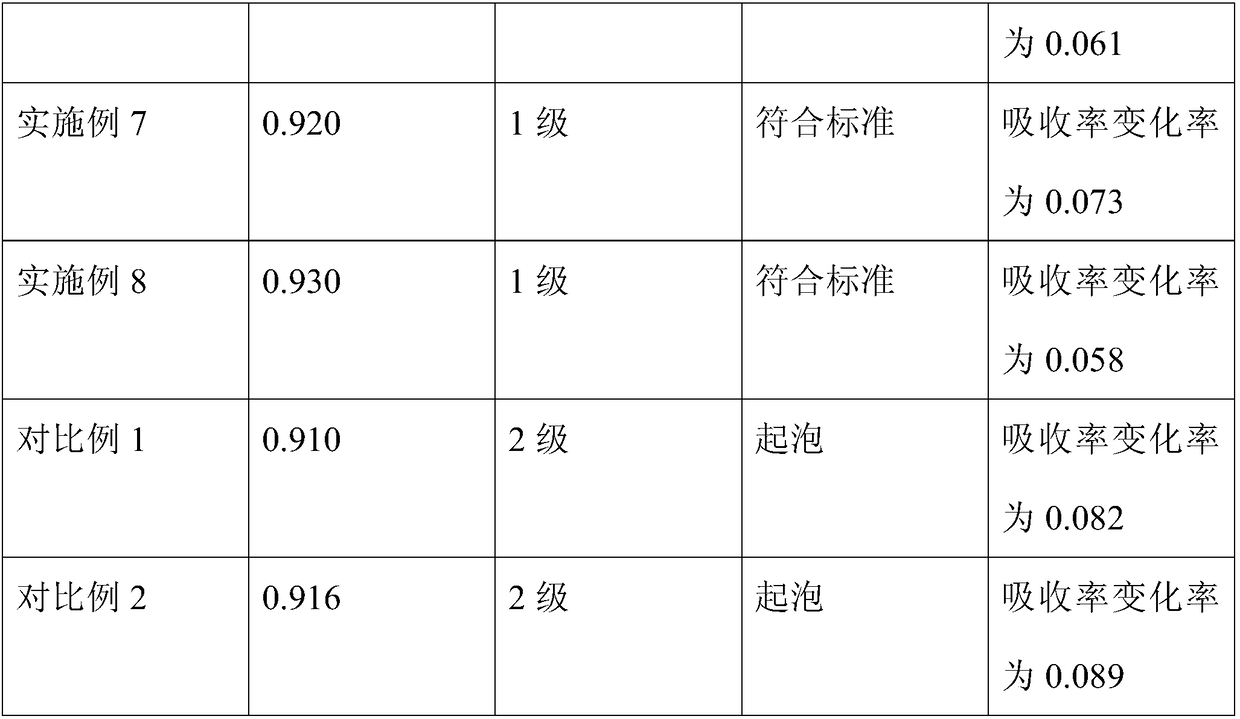

Examples

Embodiment 1

[0048] A solar water heater, comprising a cylindrical water storage tank, a light-to-heat conversion component capable of exchanging heat with the water storage tank, the light-to-heat conversion component has a substrate and a black body-absorbing coating coated on the substrate, The black body absorbing coating sequentially includes a 60nm silver infrared reflective layer, a 10nm nickel oxide barrier layer, a 0.5 μm graphene absorbing layer, a 10nm dichromium trioxide auxiliary absorbing layer and a 20nm silicon nitride antireflection layer starting from the substrate.

[0049] The preparation method of the black body absorbing coating is:

[0050] (1) Ultrasonic the substrate in acetone for 10 minutes, then take it out and rinse it with deionized water; then ultrasonically clean it with ethanol for 10 minutes, then rinse it with deionized water; finally soak it in ethanol for 5 minutes, and dry it with nitrogen;

[0051] (2) With silver as the target material, in a vacuum of ...

Embodiment 2

[0057] The difference from Example 1 is that the black body absorbing coating sequentially includes a 90nm silver infrared reflective layer, a 60nm nickel oxide barrier layer, a 20 μm graphene absorbing layer, a 20nm chromium trioxide auxiliary absorbing layer, and a 50nm Silicon nitride anti-reflection layer.

[0058] (1) Ultrasonic the substrate in acetone for 10 minutes, then take it out and rinse it with deionized water; then ultrasonically clean it with ethanol for 15 minutes, then rinse it with deionized water; finally soak it in ethanol for 5 minutes, and dry it with nitrogen;

[0059] (2) With silver as the target material, in a vacuum of 8.5×10 -4 Under the environment of Pa, adjust the sputtering distance to 90mm, pass in the sputtering gas argon, adjust the sputtering pressure to 0.4Pa, and sputter to obtain an infrared reflective layer made of silver with a thickness of 80nm;

[0060] (3) Pre-pump the magnetron sputtering vacuum chamber to a background vacuum of 8...

Embodiment 3

[0065] The difference from Example 1 is that the black body absorbing coating sequentially includes an infrared reflective layer made of 80nm copper, a 50nm nickel oxide barrier layer, a 30 μm graphene absorbing layer, a 40nm dichromium oxide auxiliary absorbing layer and a 40nm Silicon nitride anti-reflection layer.

[0066] The difference between the preparation method of the black body absorbing coating and Example 1 is that the target in step (2) is replaced by a copper target.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com