Calcium-phosphorus compound-magnesium composite coating for bone implanting and preparation method thereof

A composite coating, compound technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

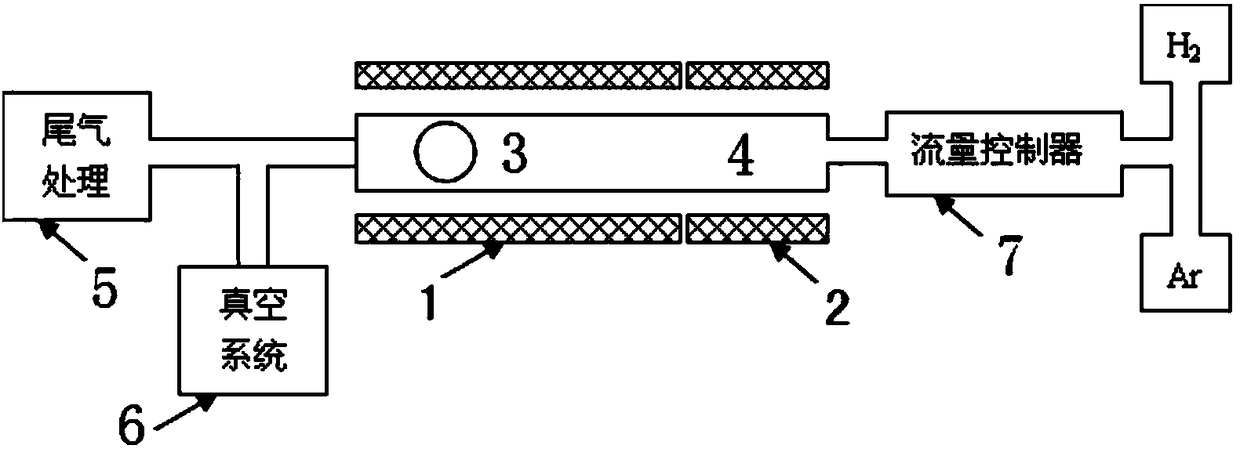

Method used

Image

Examples

Embodiment 1

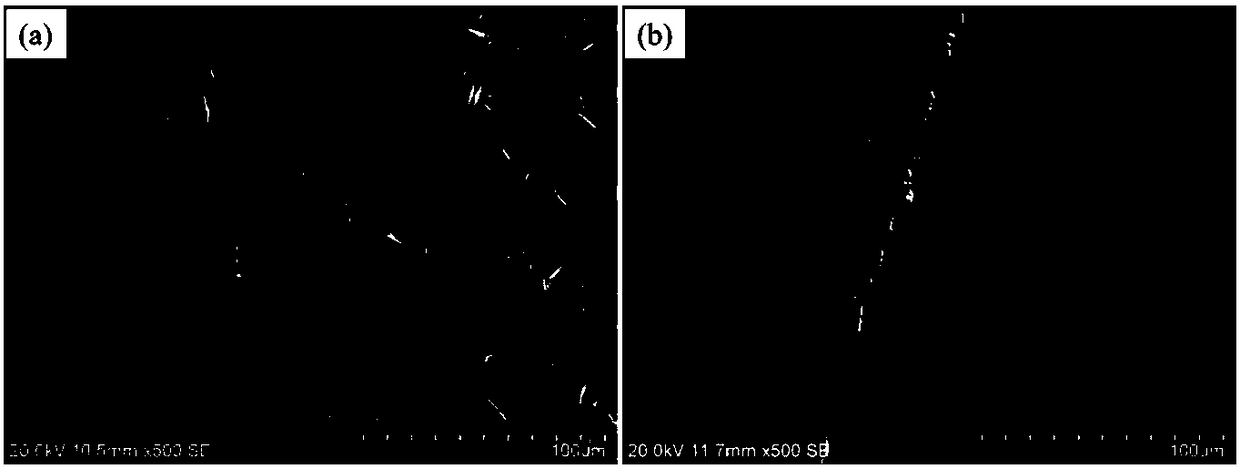

[0034] The flaky pure titanium (Ti) sample was polished to 2000# with sandpaper, and after ultrasonic cleaning with acetone, absolute ethanol and deionized water in sequence, it was placed in a NaOH solution with a concentration of 3mol / L at 80°C for 24h; then the preparation containing NaCl 100mM / L, CaCl 2 3mM / L,NH 4 h 2 PO 4 2mM / L and trishydroxymethylaminomethane (TRIS) 50mM / L solution that has the function of accelerating the deposition of calcium-phosphorus compounds; after the base is heated, the matrix is rinsed with deionized water for three times and then cleaned with an ultrasonic cleaner for 1h, and finally The cleaned substrate was deposited in the above deposition solution at a temperature of 50° C. for 12 hours. Such as figure 2 As shown, the prepared calcium phosphorus coating is mainly tile-shaped and presents a porous surface, and the thickness of the coating is about 20 μm. Its X-ray diffraction spectrum is as Figure 4 As shown in a, the composition...

Embodiment 2

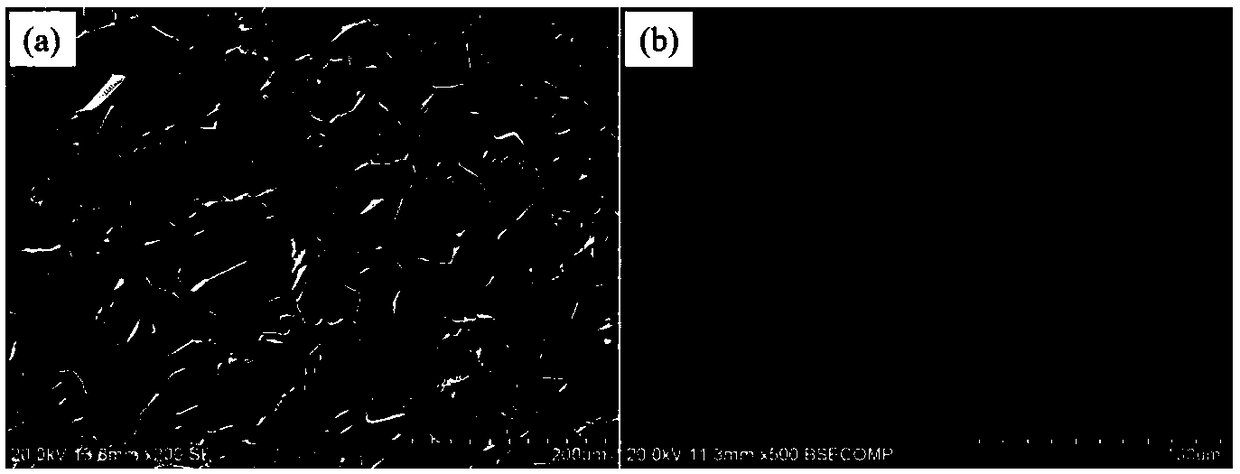

[0036] The substrate sample with the calcium-phosphorus coating prepared by the dried example 1 is placed in the deposition chamber furnace body 1, the pure magnesium block is placed in the target position of the evaporation chamber, and the dried prepared substrate with the calcium-phosphorus coating is placed At a position 300mm away from the evaporation source, vacuumize to 10 -4Below Pa, wash with high-purity argon for at least 3 times to remove air and ensure an oxygen-free environment. The evaporation temperature of pure magnesium is 600°C, the working vacuum is 5Pa, the deposition temperature is set at 150°C, and the deposition time is 0.5h. The magnesium block evaporates into magnesium vapor that diffuses and deposits on the surface of the substrate. After the reaction is completed, it is cooled to room temperature with the furnace. Such as image 3 shown. The deposited metal magnesium coating is composed of large particles of pure magnesium, and there is a certain g...

Embodiment 3

[0038] The flaky pure titanium (Ti) sample was polished to 2000# with sandpaper, and after ultrasonic cleaning with acetone, absolute ethanol and deionized water in sequence, it was placed in a NaOH solution with a concentration of 1mol / L at 80°C for 24h; then the preparation containing NaCl 120mM / L, CaCl 2 3mM / L,NH 4 h 2 PO 4 4mM / L and trishydroxymethylaminomethane (TRIS) 50mM / L solution that has the function of accelerating the deposition of calcium-phosphorus compounds; after the base is heated, the matrix is rinsed with deionized water for three times and then cleaned with an ultrasonic cleaner for 1h, and finally The cleaned substrate is deposited in the above deposition solution at a temperature of 50° C. for 8 hours, and the thickness of the prepared calcium phosphorus coating is about 10 μm. Put the pure magnesium block into the target position of the evaporation chamber, place the dried and prepared substrate with calcium-phosphorus coating at a position 300mm aw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com