Graphene and low-cost preparation method thereof

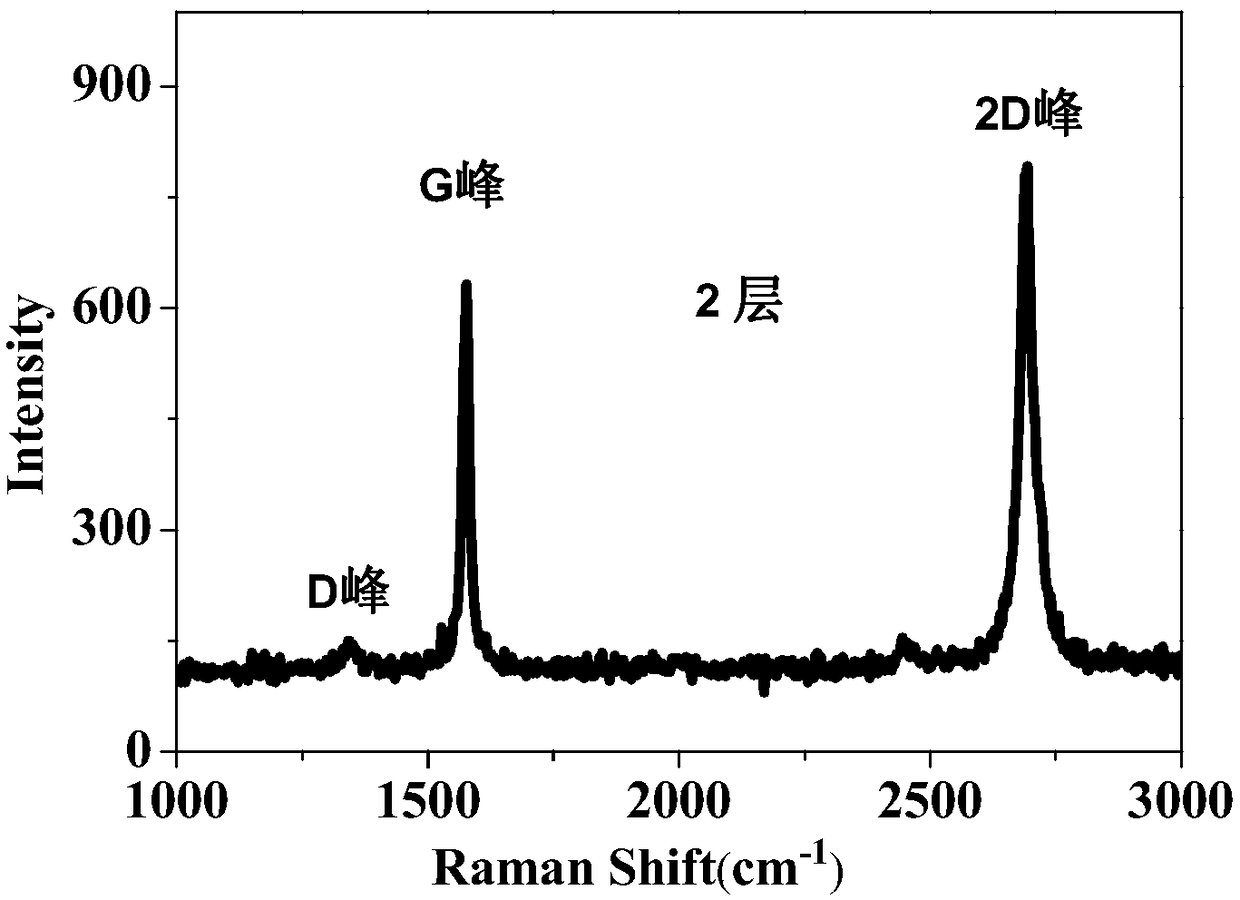

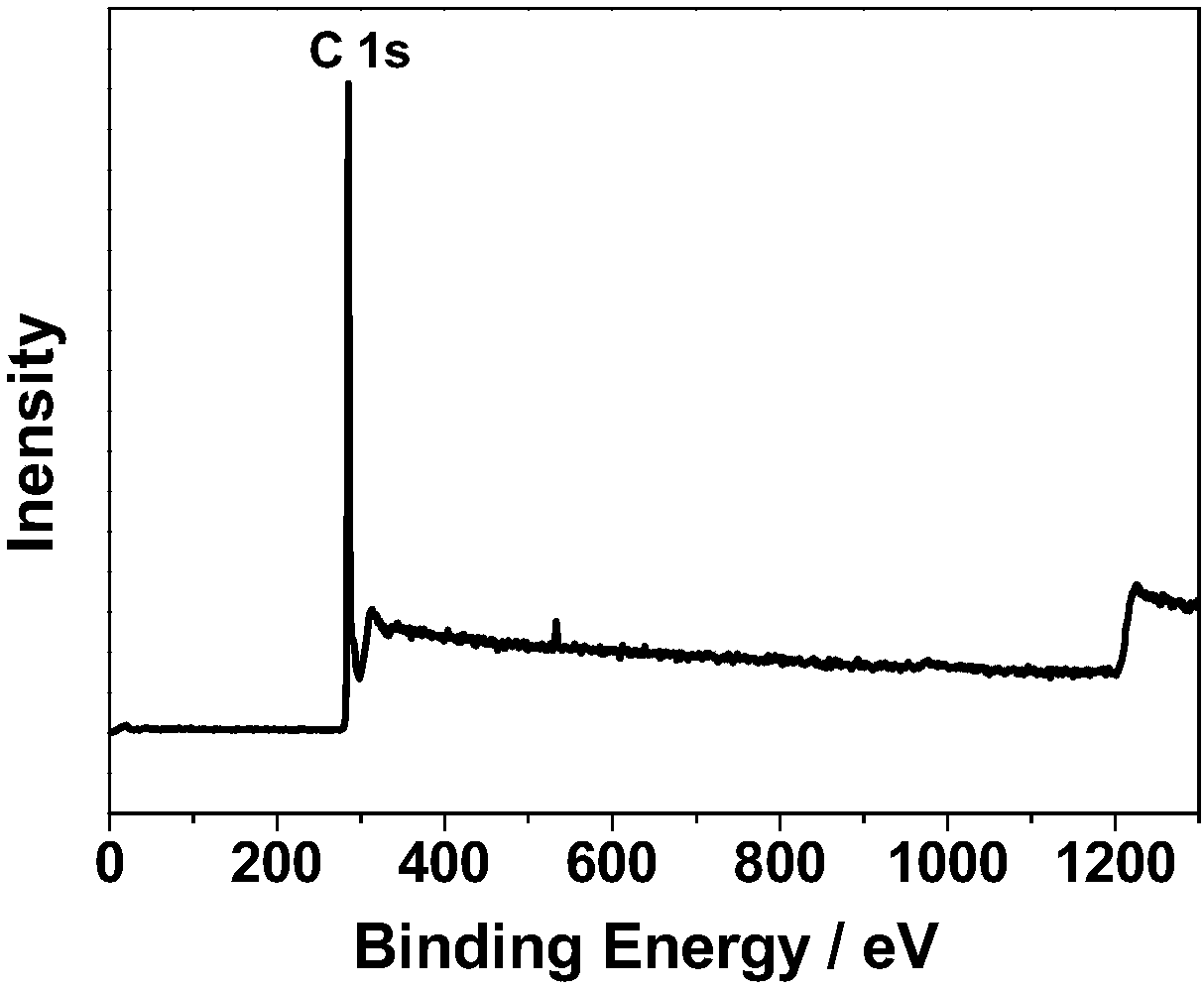

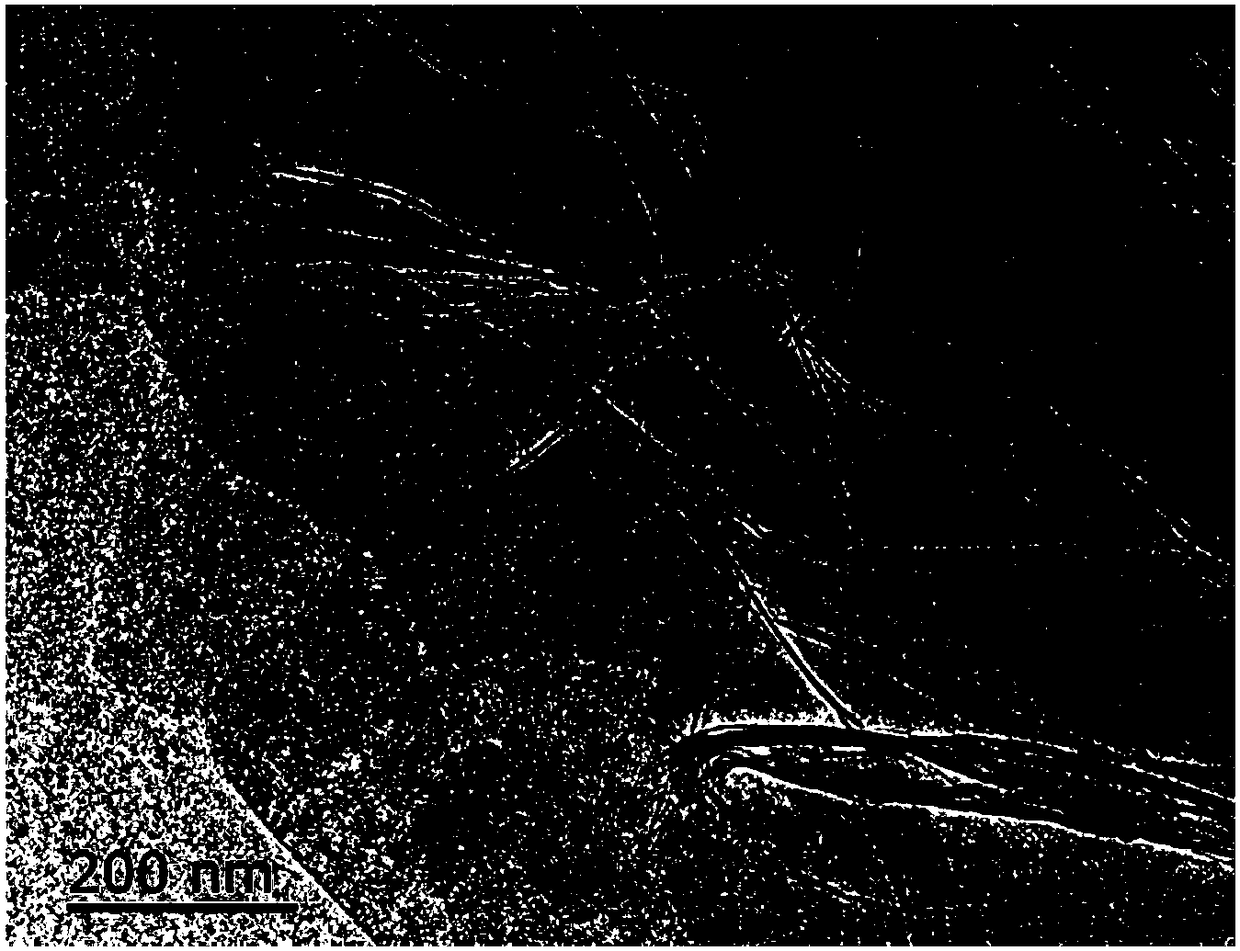

A graphene, low-cost technology, applied in the field of graphene and its low-cost preparation, can solve the problems of high cost, difficult scale production, difficult transfer, etc., achieve high room temperature electrical conductivity and thermal conductivity, reduce raw material costs, The effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A kind of low-cost preparation method of graphene of the present invention specifically comprises the following steps:

[0046](1) Cut the plastic product into a solvent and place it in an ultrasonic cleaner for cleaning for a period of time to remove the printing ink and attached pollutants on the surface of the plastic bag. The plastic products may be discarded plastic products, such as plastic bags, plastic film or plastic skin of plastic bottles, etc., and may be polyethylene plastic products, polystyrene plastic products or polypropylene plastic products.

[0047] In this step, the ultrasonic frequency is 100-1000 W, and the ultrasonic time is 5-60 min. The selected cleaning solvent is absolute ethanol, acetone, tetrahydrofuran, ethyl acetate, diethyl ether or dimethylformamide.

[0048] (2) Use a precision cutter to break the cleaned plastic product into small pieces, and then wash it again with a solvent; the selected solvent is the same as in step (1).

[0049...

Embodiment 1

[0059] Step 1: Cut the polyethylene plastic bag into tetrahydrofuran and place it in an ultrasonic cleaning machine at 300W for 40 minutes to remove the printing ink and attached pollutants on the surface of the plastic bag;

[0060] Step 2: Use a precision cutter to break the cleaned polyethylene plastic bag into small pieces, and then wash it again with tetrahydrofuran, the method is the same as step 1;

[0061] Step 3: Put the small pieces of polyethylene plastic bags in a ball mill tank at a ball-to-material ratio of 50:1 and mill them at 6000rmp for 70 minutes to obtain curly polyethylene plastic bag micro-chips; the obtained micro-chips have a diameter of 40-70 microns;

[0062] Step 4: Place the polyethylene plastic bag micro-fragments in a vacuum furnace for carbonization at 1200°C for 20 minutes, and ball mill the carbonized powder blocks at 4000rmp for 60 minutes to obtain carbonized powder; the vacuum degree in the vacuum furnace is -3 MPa; the particle size of the o...

Embodiment 2

[0067] Step 1: Cut the polyethylene plastic bag into acetone and place it in an ultrasonic cleaning machine at 400W for 30 minutes to remove the printing ink and attached pollutants on the surface of the plastic bag;

[0068] Step 2: Use a precision cutter to break the cleaned polyethylene plastic bag into small pieces, and then clean it again with acetone; the method is the same as step 1;

[0069] Step 3: Put the small pieces of polyethylene plastic bags in a ball mill tank at a ball-to-material ratio of 70:1 and mill them at 9000rmp for 50 minutes to obtain curly polyethylene plastic bag micro-chips; the diameter of the obtained micro-chips is 10-30 microns;

[0070] Step 4: Place the polyethylene plastic bag micro-fragments in a vacuum furnace for carbonization at 1300°C for 20 minutes, and ball mill the carbonized powder block at 5000rmp for 80 minutes to obtain carbonized powder; the vacuum degree in the vacuum furnace is -3 MPa; The particle diameter of the carbonized po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com