Method for preparing surface-enhanced Raman substrate by improving film-substrate bonding force

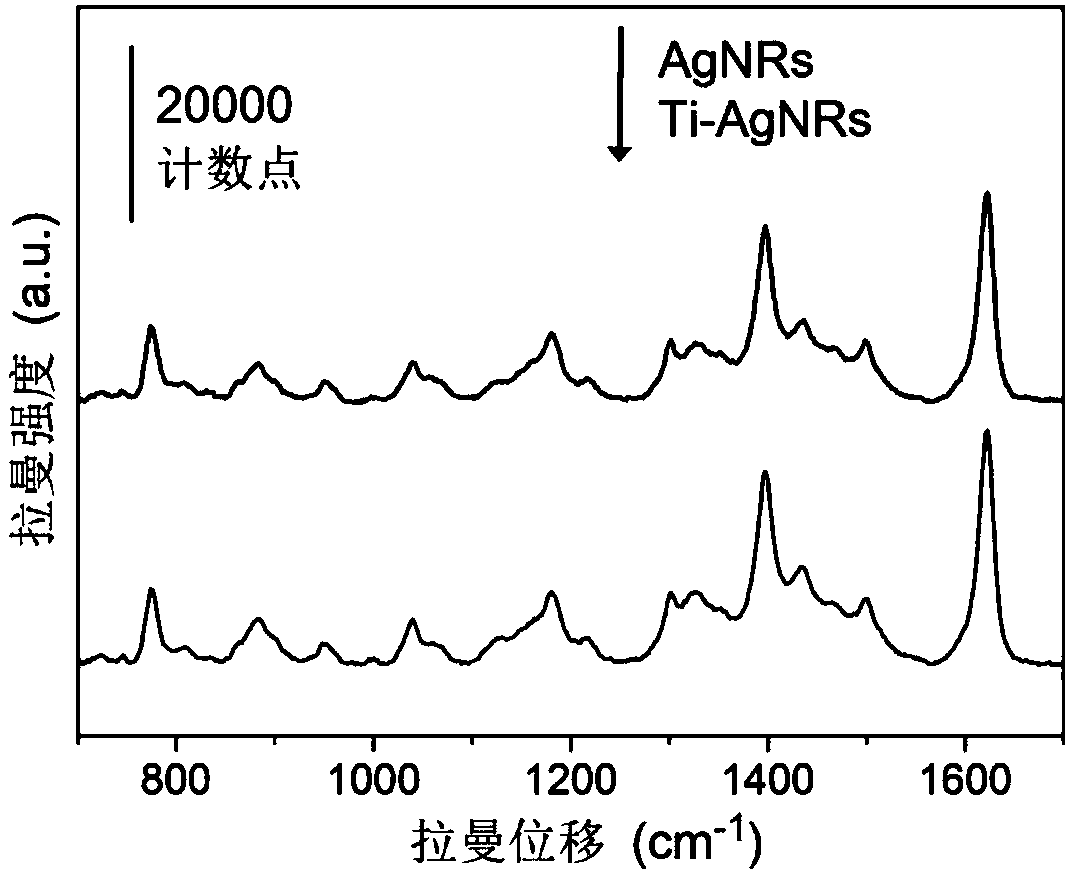

A surface-enhanced Raman and film-based bonding technology, which is applied in the plating of superimposed layers, ion implantation plating, gaseous chemical plating, etc. Mann technology development, affecting the practical application of SERS substrates, etc., to achieve the effects of improving substrate adhesion, promoting diffusion and interaction, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1).Use acetone, alcohol, and deionized water to ultrasonically clean silicon substrates, glass, and other substrates in sequence and dry them in the air;

[0027] 2). Fix the cleaned substrate on the sample stage of the electron beam evaporation coating machine, and pump the chamber of the coating machine to a vacuum degree of 10 -5 Pa level;

[0028] 3). Using metal Ti as the target material, a transition layer film is plated on the substrate, and the incident angle of the electron beam is adjusted to 0°, and the evaporation rate of Ti is The deposition thickness is 15nm;

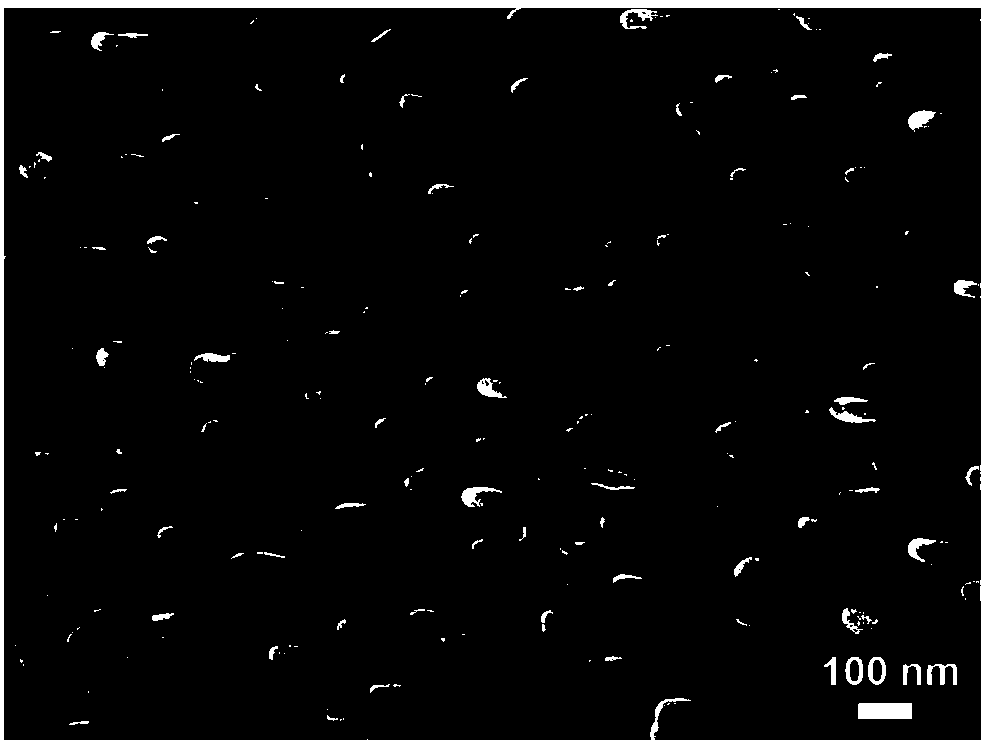

[0029] 4). Using metallic Ag as the target material, plate an Ag nanorod array thin film on the transition layer, adjust the incident angle of the electron beam to 85°, and make the sample stage static, and grow inclined silver nanorods with a nanorod length of 700nm array film;

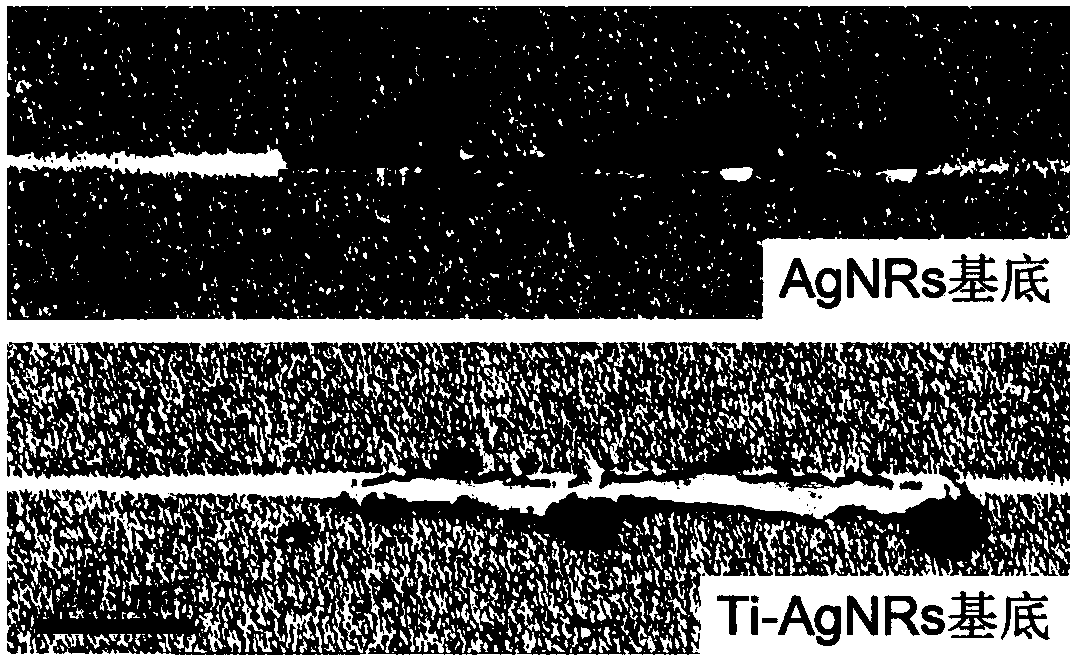

[0030] 5).Using the nano-scratch method to evaluate the film-base bonding force of the film, a diamond indenter is u...

Embodiment 2

[0035] 1).Use acetone, alcohol, and deionized water to ultrasonically clean silicon substrates, glass, and other substrates in sequence and dry them in the air;

[0036] 2). Fix the cleaned substrate on the sample stage of the electron beam evaporation coating machine, and pump the chamber of the coating machine to a vacuum degree of 10 -5 Pa level;

[0037] 3). Using metal Ti as the target material, a transition layer film is plated on the substrate, and the incident angle of the electron beam is adjusted to 0°, and the evaporation rate of Ti is The deposition thickness is 25nm;

[0038] 4). Using metallic Ag as the target material, plate an Ag nanorod array thin film on the transition layer, adjust the incident angle of the electron beam to 86°, and make the sample stage static, and grow obliquely inclined silver nanorods with a nanorod length of 800nm array film;

[0039] 5).Using low-temperature atomic layer deposition technology, set the reaction chamber temperature o...

Embodiment 3

[0045] 1).Use acetone, alcohol, and deionized water to ultrasonically clean silicon substrates, glass, and other substrates in sequence and dry them in the air;

[0046] 2). Fix the cleaned substrate on the sample stage of the electron beam evaporation coating machine, and pump the chamber of the coating machine to a vacuum degree of 10 -5 Pa level;

[0047] 3). Using metal TiN as the target material, a transition layer film is plated on the substrate, and the incident angle of the electron beam is adjusted to 0°, and the evaporation rate of TiN is The deposition thickness is 40nm;

[0048] 4). Using metallic Ag as the target material, plate an Ag nanorod array thin film on the transition layer, adjust the incident angle of the electron beam to 87°, and make the sample stage static, and grow obliquely inclined silver nanorods with a nanorod length of 900nm array film;

[0049] 5).Using low-temperature atomic layer deposition technology, set the temperature of the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com