Ternary complex aerogel and preparation method and electrode slice preparation technology

A ternary composite and preparation technology, applied in the field of airgel, can solve the problems of difficulty in obtaining uniform products, expensive equipment, and reduced Coulombic efficiency, so as to avoid the decrease of effective density, enhance the electron migration rate, and improve the mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

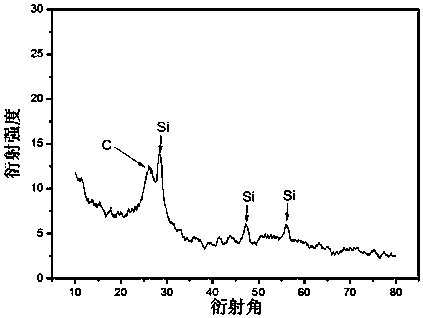

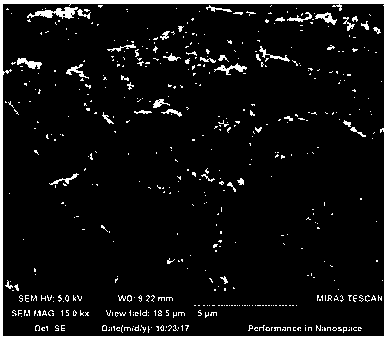

[0041] Preparation of negative electrode material: at room temperature, add 100 mg of amorphous silicon powder to 10 ml of anhydrous methanol, ultrasonically vibrate, add 800 μl of APTES silane coupling agent, and magnetically stir for 2 hours to form a suspension;

[0042] The reaction product was collected by centrifugation, washed three times with ethanol, and dried in an oven to obtain surface aminated amorphous silicon.

[0043] Graphene oxide was prepared by the modified Hummers method. First, 2 g of flake graphite and 1 g of sodium nitrate were added to 46 ml of concentrated sulfuric acid, and magnetically stirred in an ice bath (below 20 °C) for 0.5 hours, then potassium permanganate was added, and the stirring was continued for 1 hour. ; Then put the above solution into an oil bath to keep the temperature at 35°C and stir magnetically for 4 hours; then adjust the temperature to about 95°C, slowly add 92ml of water, stir with a glass rod, then adjust the temperature at ...

Embodiment 2

[0055] Preparation of negative electrode material: At room temperature, add 50 mg of amorphous silicon powder to 5 ml of anhydrous methanol, ultrasonically, add 400 μl of APTES silane coupling agent, and stir magnetically for 2 hours to form a suspension; collect the reaction product by centrifugation and wash with ethanol Three times, put it in an oven to dry to obtain amorphous silicon with surface amination. The preparation of graphene oxide is the same as in Example 1. Measure 0.5g of carbon nanotubes, grind, put into a tube furnace and calcined at 600 ° C for 2h; add the calcined product to a mixed acid of 16ml of concentrated nitric acid and concentrated sulfuric acid (volume ratio concentrated sulfuric acid: concentrated nitric acid=3: 1, heated to 80 ℃ and stirred for 6 hours, and repeatedly centrifugally cleaned with deionized water. The acidified carbon nanotube dispersion solution was obtained, and its pH was about 4. Graphene oxide and aminated amorphous silicon we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com