Lipase-calcium phosphate compound enzyme crystal, preparation method thereof and method for catalyzing and synthesizing clindamycin palmitate by using lipase-calcium phosphate compound enzyme crystal

A technology for synthesizing clindamycin and palmitate, which is applied in the direction of biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems of resin becoming solid waste, not meeting sustainable development, and reducing enzyme activity, so as to improve production Safety, high yield, effect of reducing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1: Preparation of Clindamycin Free Base:

[0056] Dissolve 2.5g of clindamycin hydrochloride in 6mL of deionized water, mix well, slowly add 6mL of NaOH (1mol / L) and stir constantly, then let it stand for a while, remove the upper layer of water, and the lower layer of precipitation is 45 Dry in a vacuum drying oven at ℃ for one day; the white solid obtained is clindamycin free base.

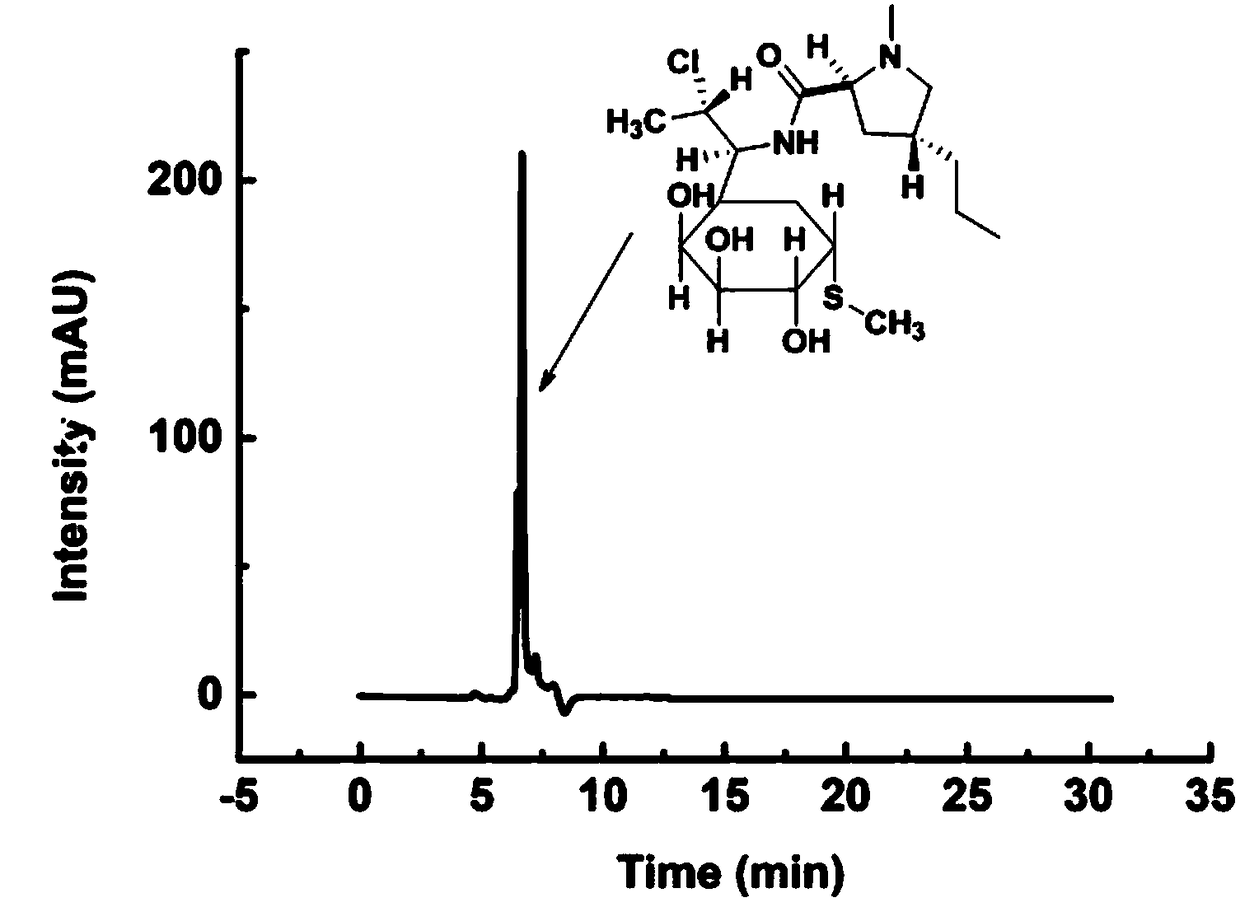

[0057] Such as figure 1 As shown, the Clindamycin free base HPLC analysis profile prepared in Example 1; Take 1 mg of Clindamycin free base into 1 mL of methanol, mix well and filter with a 0.22 μm organic phase filter membrane. Obtain the sample, the following sample preparation process is the same; HPLC conditions: C18 column, column temperature 25℃, 226nm, 0.5mL / min, mobile phase: methanol: 3% ammonium acetate = 70:30, clindamycin free The alkali retention time is 6.23min.

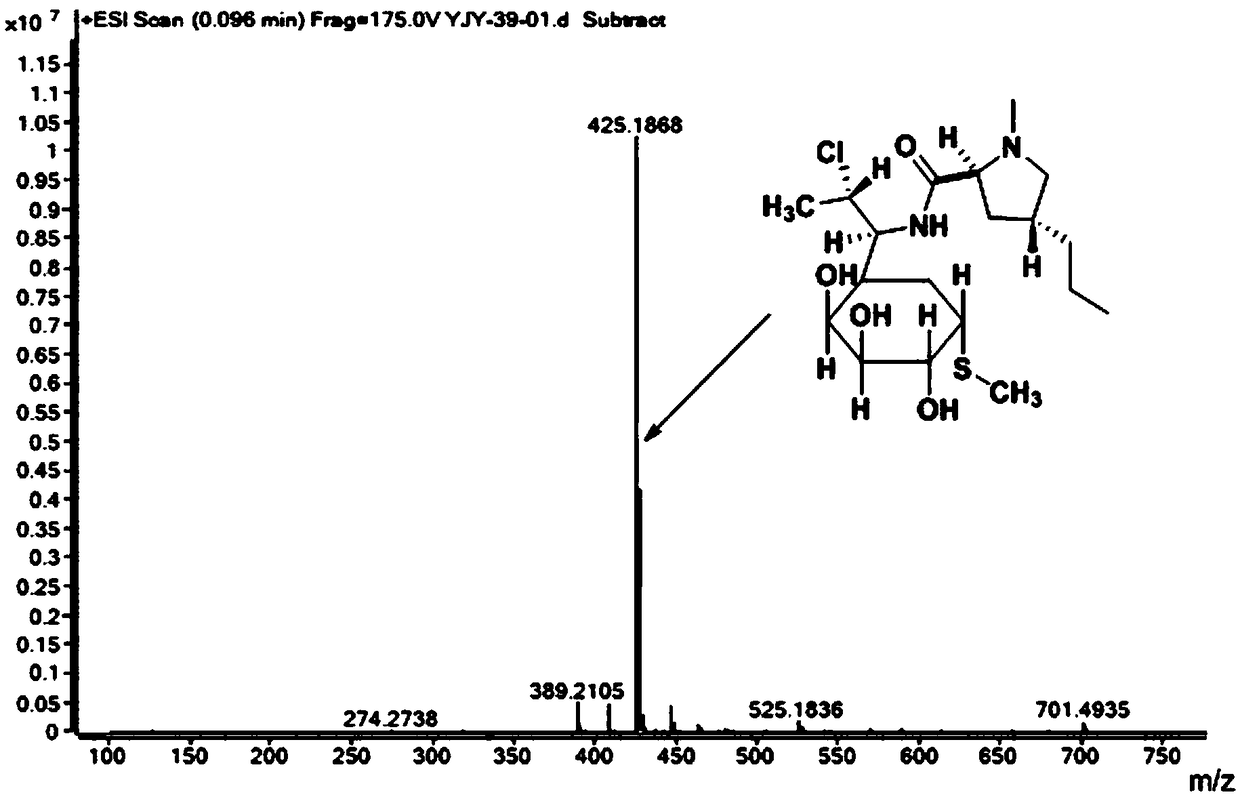

[0058] Such as figure 2 As shown, the LC-MS spectrum of clindamycin free base prepared in Example 1: (m / z, ...

Embodiment 2

[0059] Example 2: Preparation of calcium phosphate crystals:

[0060] 5mL of phosphate buffer (PBS, 20mM, pH 6.7) containing 0.25mg / ml Thermomyces lanuginosa lipase (TLL) was added with 100μL of calcium chloride solution (200mM), and the mixture was kept at 4℃ Cultivate for 24 hours under conditions; then centrifuge at 10000 rpm for 5 minutes to remove the supernatant to obtain a white precipitate; finally, the obtained precipitate is washed three times with deionized water to obtain calcineurin crystals of Thermomyces lanuginosa lipase.

Embodiment 3-1

[0063] Example 3-1: Preparation of Clindamycin Palmitate:

[0064] Weigh 13.25mg (0.3125mmol) of clindamycin free base and 26.48mg (0.9375mmol) of vinyl palmitate into a centrifuge tube with 6.25mL of petroleum ether, and add calcineurin crystals (containing 150mg of Cotton-like Thermomyces spores lipase), shake in a shaker at 200 rpm for 24 hours at 30°C; after the reaction, centrifuge, and wash the filter residue with the washing solvent petroleum ether to obtain the supernatant; The supernatant was heated under reduced pressure and spin-dried, dissolved in dichloromethane and adjusted to pH 1-2 with dilute hydrochloric acid, then heated under reduced pressure to spin-dry the solvent, dissolved in ethanol and added acetonitrile, stirred at 0°C for 4h, and finally Cold filtered and dried to obtain a white solid, which is clindamycin palmitate.

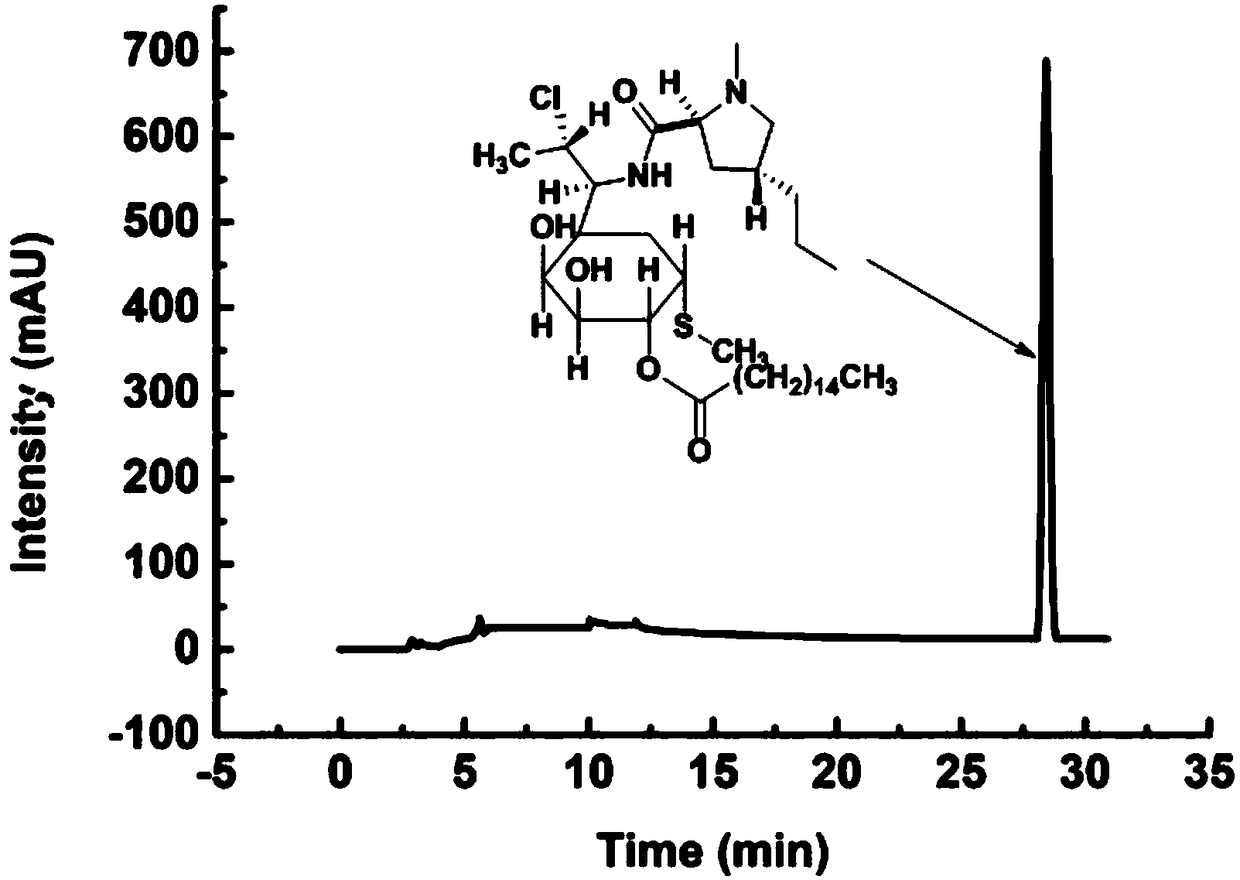

[0065] Such as image 3 As shown, the HPLC analysis pattern of clindamycin palmitate prepared in Example 3-1; HPLC conditions: C18 colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com