Purified water beautifying solution after extraction of endive polysaccharide and preparation method of purified water beautifying solution

A technology of polysaccharides and purified water, which is applied in pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve problems such as energy consumption, and achieve the effects of maintaining skin, accelerating wound healing, and restoring skin physiological functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0038] A method for preparing a refined water beauty liquid after extraction of chicory polysaccharides includes the following steps:

[0039] Step 1. Weigh a certain quality of fresh chicory, clean it, place it in boiling water for 2 minutes, take it out and cool to room temperature, after slicing it, soak it in an ethanol solution with vitamin E dissolved in it for 60 seconds, take it out, dry, crush, and sieve it. The coarse powder raw materials are mixed with water according to the material-to-night ratio of 1:20, adjusted to pH 4.0 with dilute hydrochloric acid, and then transferred to the high-shear disperser for dispersion treatment, and then transferred to the enzymatic hydrolysis tank, adding 25mg / l of neutral Protease enzymatic hydrolysis, and then filter to remove the filter residue to obtain the first extract of chicory polysaccharides;

[0040] Step 2. The first extract of inulin prepared in step 3 is filtered through an ultrafiltration membrane separation device, and ...

specific Embodiment approach 2

[0052] According to the first embodiment of a chicory polysaccharide refined water beauty liquid after extraction, the chicory polysaccharide refined water beauty liquid consists of 200 parts of chicory polysaccharide first extract, 1 part Made of high-purity petal oil, 5 parts of hyaluronic acid, 1 part of squalane, and 1 part of pantothenic acid.

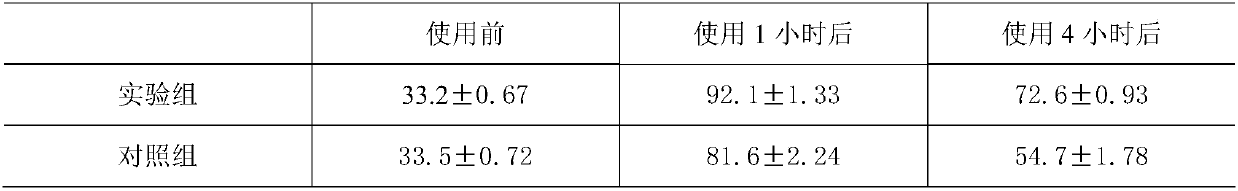

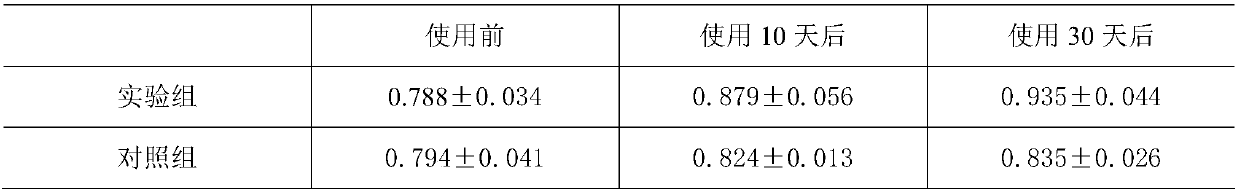

[0053] The refined water beauty liquid after extraction of chicory polysaccharides described in this embodiment is subjected to multiple intact skin irritation tests and one-time broken skin irritation tests: the method of multiple intact skin irritation tests is to choose a healthy white home weighing 20-25kg 3 rabbits, cut off the hair on both sides of the back spine of the white rabbit 24 hours before the test, and the hair removal range is about 3cm*3cm on the left and right. On the next day, 0.5 ml of the refined water beauty liquid after the extraction of the chicory polysaccharide was evenly applied to the surface of the depil...

specific Embodiment approach 3

[0056] A method for preparing a refined water beauty liquid after extraction of chicory polysaccharides includes the following steps:

[0057] Step 1. Weigh a certain quality of fresh chicory, clean it, place it in boiling water for 2-5 minutes, take it out and cool to room temperature, after slicing, soak it in an ethanol solution with vitamin E for 10-60s, take it out, dry, crush, The coarse powder raw material obtained after sieving is mixed with water according to the material-to-night ratio of 1:20~1:30, adjusted to pH 4.0~5.0 with dilute hydrochloric acid, and then transferred to a high-shear disperser for dispersion treatment, and then transferred to enzymatic hydrolysis Add 25mg / l-28mg / l neutral protease to the tank for enzymatic hydrolysis, and then filter to remove the filter residue to obtain the first extract of chicory polysaccharide;

[0058] Step 2. The first extract of inulin prepared in step 3 is filtered through an ultrafiltration membrane separation device, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com