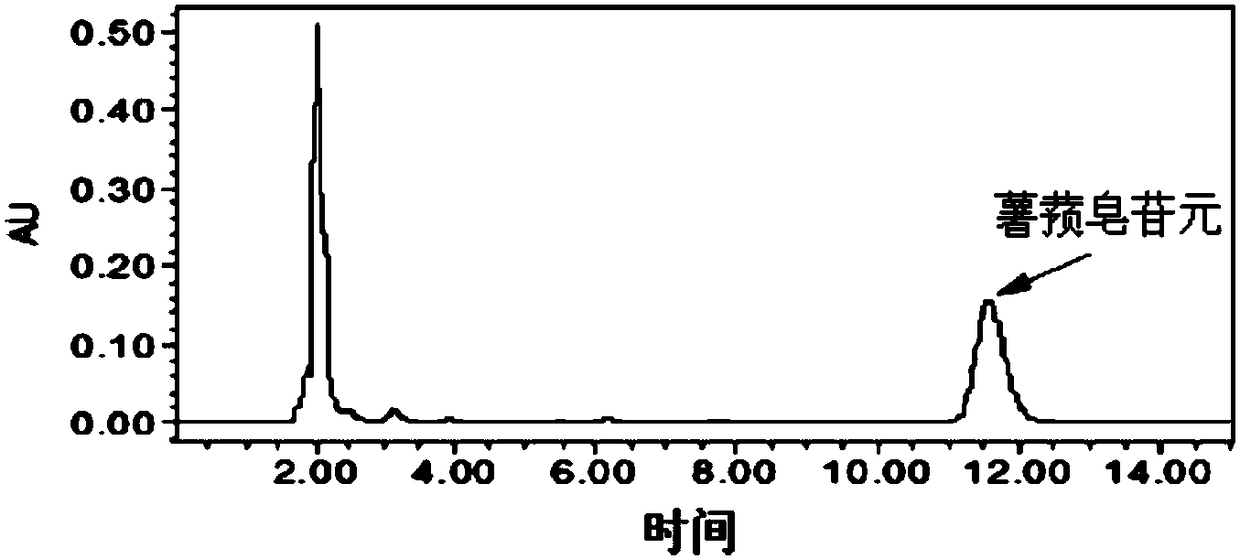

Method for preparing diosgenin from B acid DES (deep eutectic solvent) hydrolysis

A technology of diosgenin and B acid, which is applied in the direction of chemical instruments and methods, steroids, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of diosgenin polluting the environment and achieve flexible equipment technology , and the effect of good economy and simple raw material processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

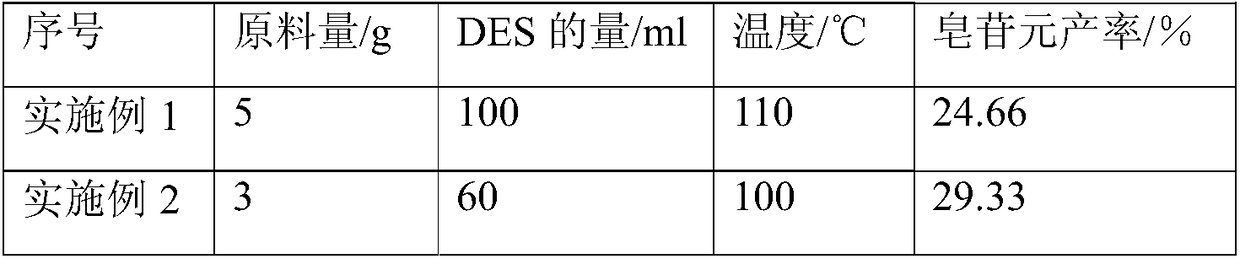

Embodiment 1

[0026] (1) heating choline chloride and citric acid according to the molar ratio of 2:1 to 69°C and melting to obtain DES;

[0027] (2) Add 5g of Dioscorea baicalensis underground rhizome raw material powder, 100ml of DES and 100ml of petroleum ether (boiling range is 90-120) into a 250ml round bottom flask, so that petroleum ether and DES form a two-phase solvent system;

[0028] (3) Set up the condensing reflux device. Turn on the condensed water and oil bath heating switches, and set the reaction temperature to 110°C. After the temperature was raised to 100°C, the hydrolysis reaction was carried out at a constant temperature for 4 hours. After the reaction is terminated, turn off the condensate water and the heating switch, take out the flask and wait for it to cool to normal temperature. The reaction solution is separated with a Buchner funnel, and the liquid petroleum ether phase rich in diosgenin is taken; the solid phase residue is washed three times with petroleum et...

Embodiment 2

[0032] (1) heating choline chloride and oxalic acid according to the molar ratio of 1:1 to 60°C and melting to obtain DES;

[0033] (2) Add 3g of Dioscorea baicalensis underground rhizome raw material powder, 60ml of DES and 60ml of petroleum ether (boiling range is 90 to 120) into a 150ml round bottom flask, so that petroleum ether and DES form a two-phase solvent system;

[0034] (3) Set up the condensing reflux device. Turn on the condensed water and oil bath heating switches, and set the reaction temperature to 100°C. After the temperature was raised to 110°C, the hydrolysis reaction was performed at a constant temperature for 4 hours. After the reaction is terminated, turn off the condensate water and the heating switch, take out the flask and wait for it to cool to normal temperature. The reaction solution is separated with a Buchner funnel, and the liquid petroleum ether phase rich in diosgenin is taken; the solid phase residue is washed three times with petroleum eth...

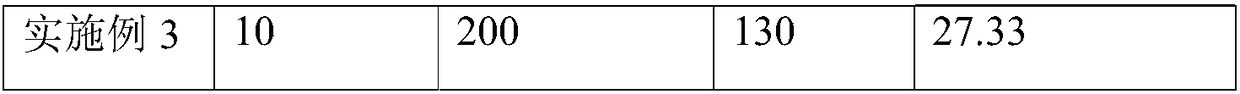

Embodiment 3

[0039] (1) Heating choline chloride and succinic acid in a molar ratio of 1:1 to 71°C to melt to obtain DES;

[0040] (2) Add 10g of Dioscorea baicalensis underground rhizome raw material powder, 200ml of DES and 200ml of petroleum ether (boiling range is 90-120) into a 150ml round bottom flask, so that petroleum ether and DES form a two-way solvent system;

[0041] (3) Set up the condensing reflux device. Turn on the condensed water and oil bath heating switches, and set the reaction temperature to 130°C. After the temperature was raised to 130°C, the hydrolysis reaction was performed at a constant temperature for 2 hours. After the reaction is terminated, turn off the condensate water and the heating switch, take out the flask and wait for it to cool to normal temperature. The reaction solution is separated with a Buchner funnel, and the liquid petroleum ether phase rich in diosgenin is taken; the solid phase residue is washed three times with petroleum ether (boiling rang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com