Aluminum acetylacetone cathode modified polymer solar cell and preparation method thereof

A technology of aluminum acetylacetonate and solar cells, applied in the field of polymer solar cells, can solve the problems of difficult preparation of ZnO nanoparticles, low adhesion, and high cost, and achieve the advantages of low cost, improved adhesion, and reduced contact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

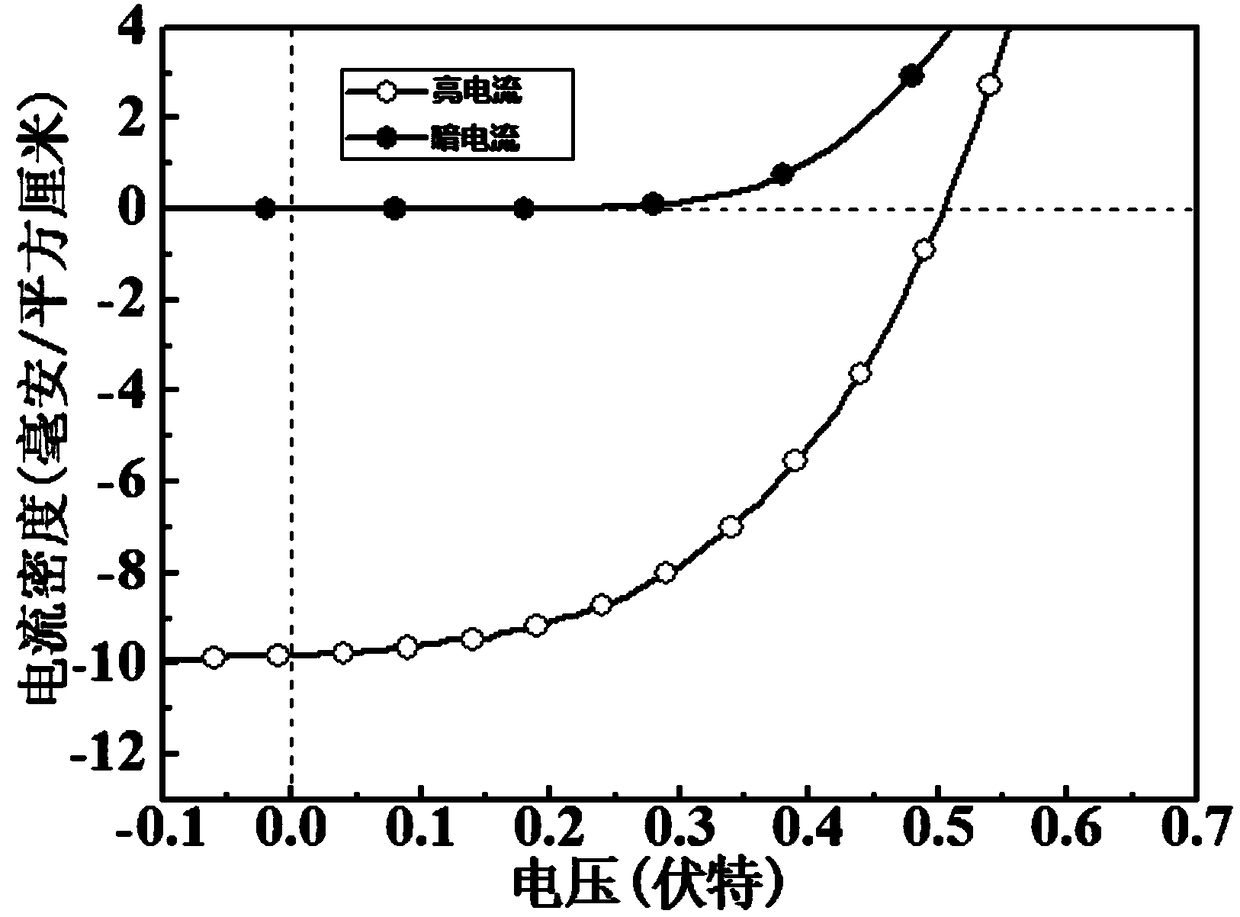

[0036] Polymer solar cell ITO / P3HT:PC without cathode modification layer 61 BM / MoO 3 / Ag preparation, concrete steps are as follows:

[0037] (1) The transparent conductive glass substrate sputtered with indium tin oxide (ITO glass substrate) was ultrasonically cleaned with acetone, isopropanol, deionized water and isopropanol for 15 minutes respectively, and the washed ITO glass substrate was placed on the Dried in an oven and moved into a nitrogen glove box with water and oxygen content less than 10 ppm for subsequent use;

[0038] (2) P3HT:PC with a mass ratio of 1:0.8 61 BM was formulated into a mixed solution with a total concentration of 36 mg / mL (P3HT:PC 61 BM solution), the solvent is o-dichlorobenzene; the P3HT:PC 61 The BM solution was spin-coated on the ITO glass at a speed of 800 rpm and 45 seconds as the active layer, and then placed in the glove box for 3.5 hours, annealed at 150°C for 15 minutes; finally placed in a vacuum thermal evaporation coating machine...

Embodiment 2

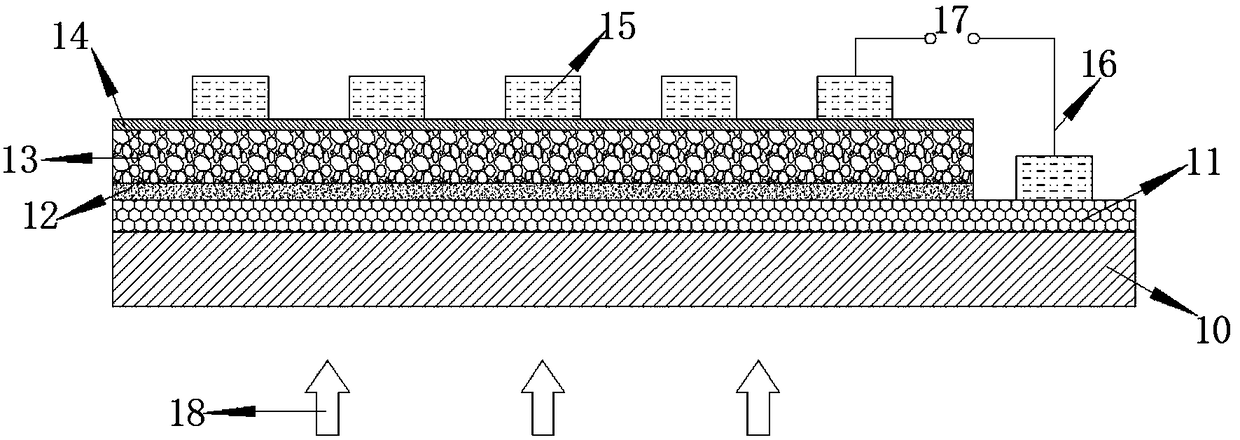

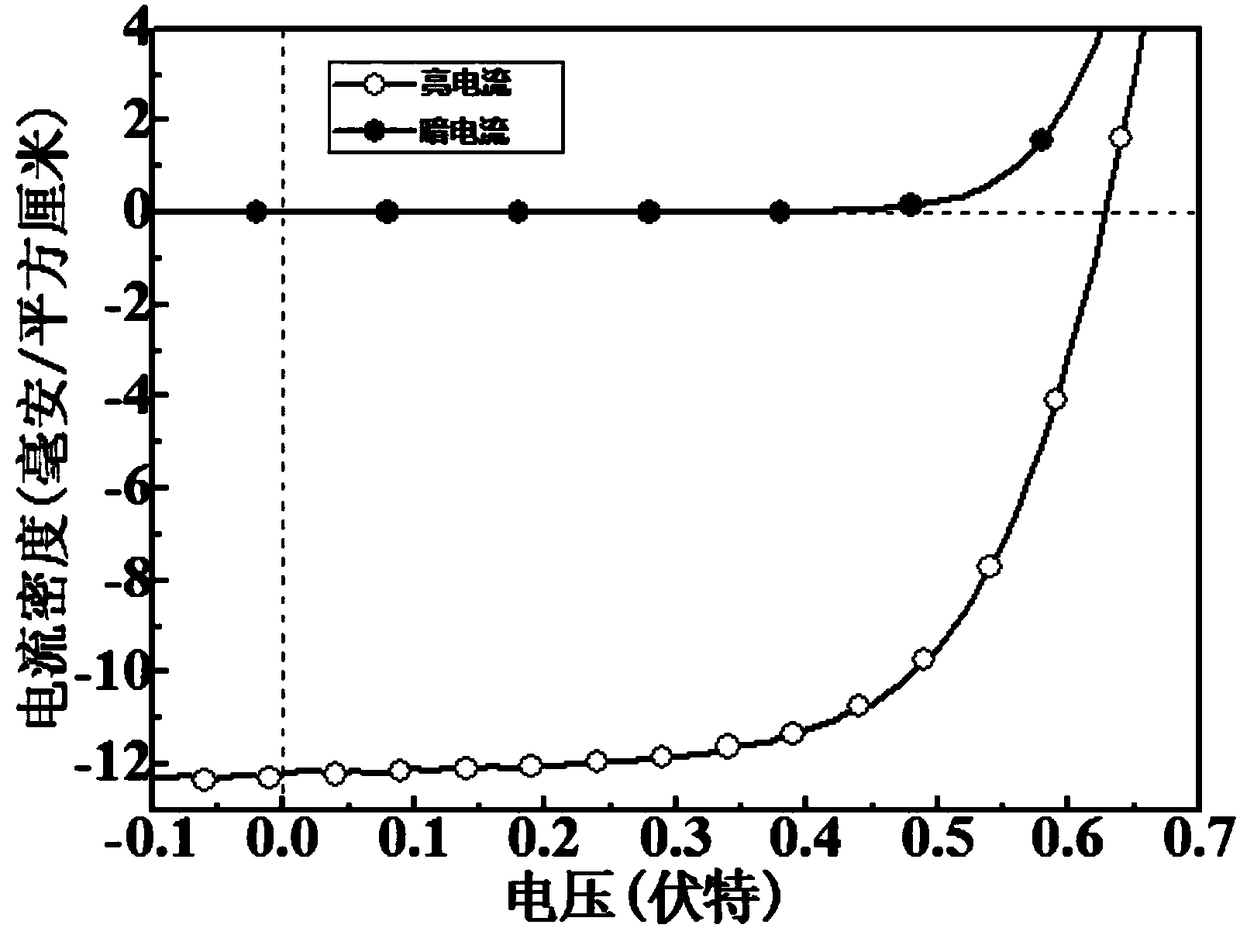

[0041] Aluminum acetylacetonate cathode modified polymer solar cells ITO / aluminum acetylacetonate / P3HT:PC 61 BM / MoO 3 / Ag preparation, concrete steps are as follows:

[0042] (1) Take 100 mg of aluminum acetylacetonate with an electronic scale, add the solvent N,N-dimethylformamide to it, and prepare a solution with a concentration of 10 wt%, then add 100 μL of ethanolamine to it, fully shake to dissolve, Obtain aluminum acetylacetonate solution, stand-by;

[0043] (2) The transparent conductive glass substrate sputtered with indium tin oxide (ITO glass substrate) was ultrasonically cleaned with acetone, isopropanol, deionized water and isopropanol for 15 minutes respectively, and the washed ITO glass substrate was placed on the Dry in an oven and transfer to a Braun nitrogen glove box with water and oxygen content less than 10 ppm for later use;

[0044] (3) The prepared aluminum acetylacetonate solution was spin-coated on the ITO glass substrate at a speed of 2000 rpm for...

Embodiment 3

[0048] Polymer solar cell ITO / PTB7:PC without cathode modification layer 71 BM / MoO 3 / Ag preparation, concrete steps are as follows:

[0049] (1) The transparent conductive glass substrate sputtered with indium tin oxide (ITO glass substrate) was ultrasonically cleaned with acetone, isopropanol, deionized water and isopropanol for 15 minutes respectively, and the washed ITO glass substrate was placed on the Dry in an oven and transfer to a Braun nitrogen glove box with water and oxygen content less than 10 ppm for later use;

[0050] (2) PTB7:PC with a mass ratio of 1:1.5 71 BM was prepared into a mixed solution with a total concentration of 20 mg / mL, and the solvent was chlorobenzene, and then spin-coated on the ITO glass substrate at 1000 rpm and 60 seconds as the active layer, and then placed in the overcoating chamber in the glove box Continue vacuuming for 3 hours, anneal at 150°C for 15 minutes; finally put MoO into a vacuum thermal evaporation coating machine to eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com