Method for constructing nano coating on surface of micro-nano structure and application of nano coating on antireflection

A nano-coating and micron-level technology, applied in coatings, electrical components, circuits, etc., can solve the problems of low solar energy utilization, and achieve the effect of facilitating large-scale preparation, improving transmittance, and requiring simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] 1) Dilute γ-aminopropyltriethoxysilane and ethanol at a volume ratio of 1:10 to obtain solution a;

[0073] 2) Dilute the dispersion of silicon dioxide nanoparticles (~30nm, negatively charged) with a mass fraction of 60% and ethanol at a volume ratio of 1:10 to obtain solution b; take 30 μL of solution a and drop it into 30 ml of solution b, that is obtaining nanoparticle coatings;

[0074] 3) At 80°C, vapor-phase deposit 1mL of solution a onto the surface of a silicon wafer with an irregular micron-scale structure;

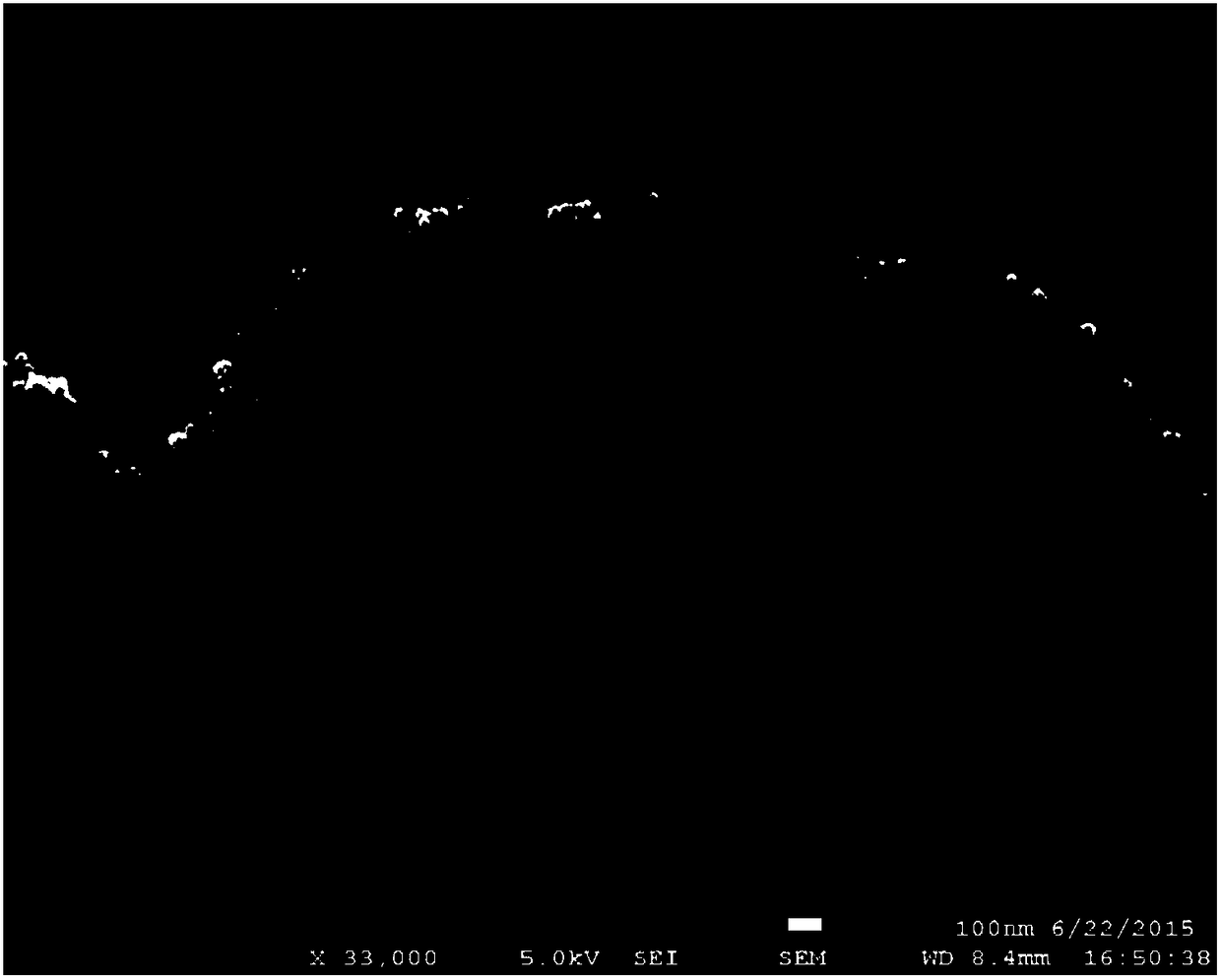

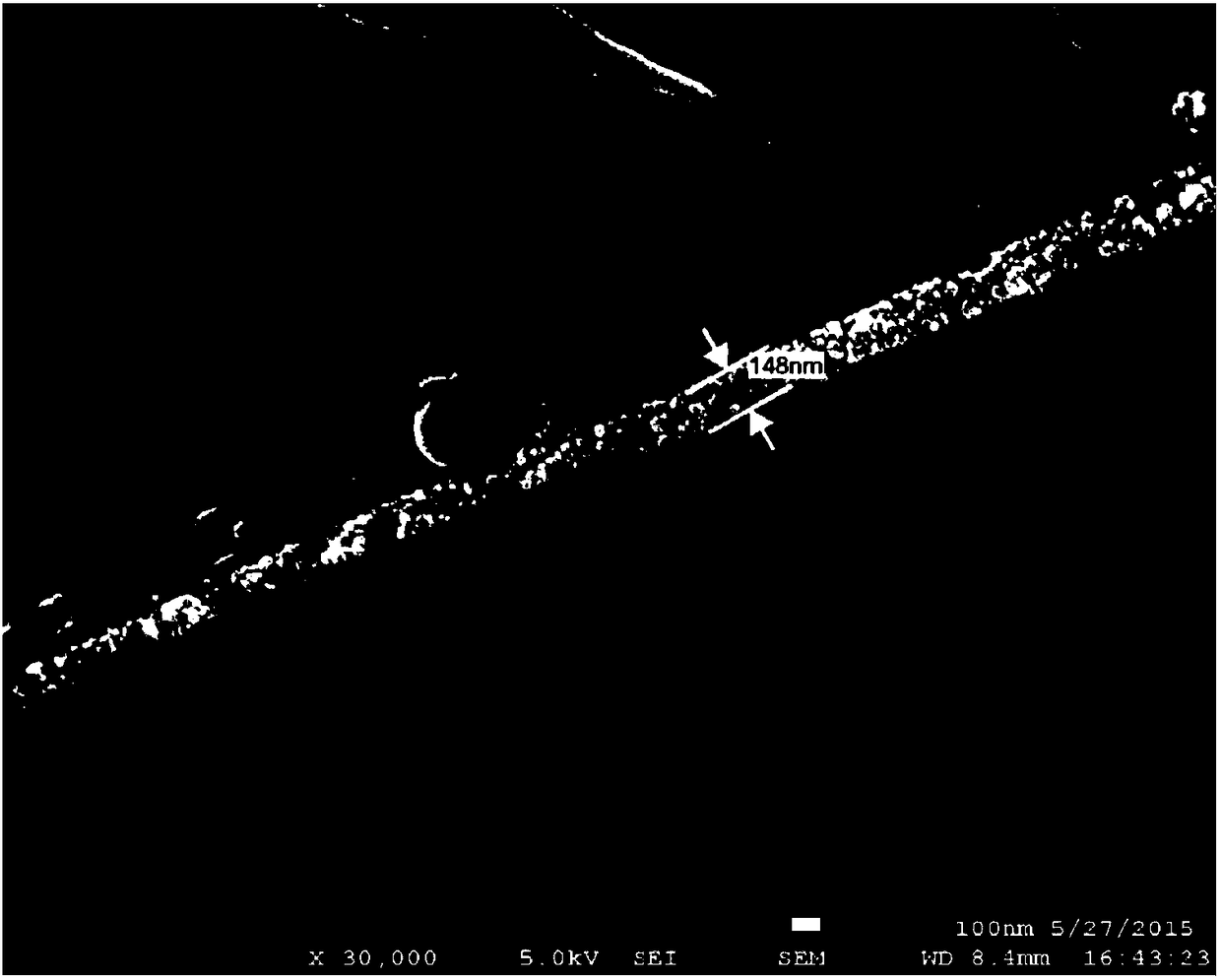

[0075] 4) At room temperature, after immersing the silicon chip of vapor deposition solution a in step (3) in the nanoparticle coating described in step (2) for 8 hours, take it out, rinse the surface with ethanol, and after drying at room temperature, irregular micron-sized A conformal, uniform thickness (approximately 150 nm) coating of silica nanoparticles was formed on the surface of the structured silicon wafer.

[0076] If the immersion time in st...

Embodiment 2

[0078] 1) Dilute γ-aminopropyltriethoxysilane and ethanol at a volume ratio of 1:100 to obtain solution a;

[0079] 2) Dilute the dispersion of silicon dioxide nanoparticles (~30nm, negatively charged) with a mass fraction of 60% and ethanol at a volume ratio of 1:100 to obtain solution b; take 300 μL of solution a and drop it into 30ml of solution b, that is obtaining nanoparticle coatings;

[0080] 3) At 80°C, vapor-phase deposit 10mL of solution a onto the surface of a silicon wafer with an irregular micron-scale structure;

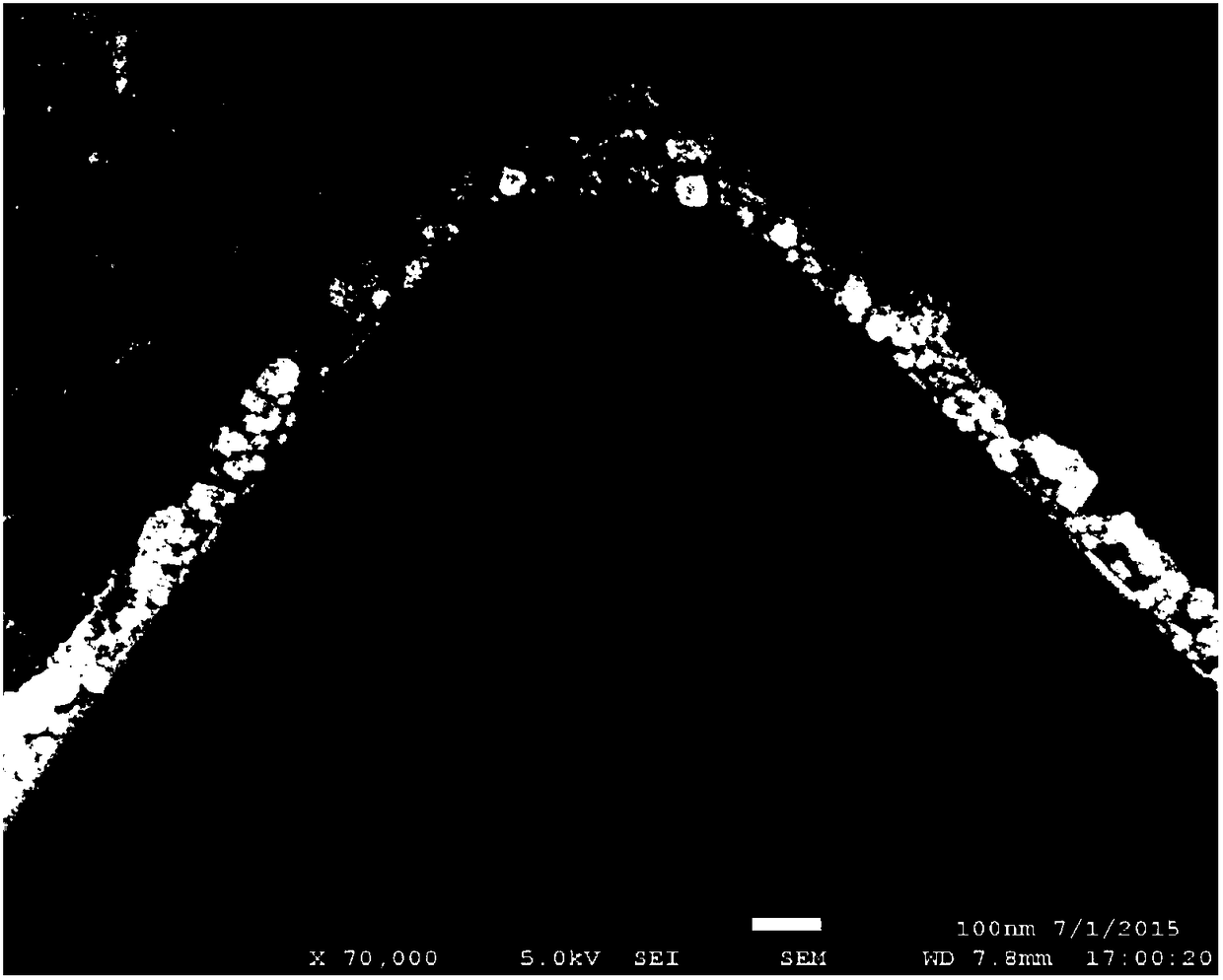

[0081] 4) At room temperature, after immersing the silicon chip of vapor deposition solution a in step (3) in the nanoparticle coating described in step (2) for 10 h, take it out, rinse the surface with ethanol, and dry it at room temperature to have irregular micron-scale A conformal, uniform thickness (approximately 200 nm) coating of silica nanoparticles was formed on the surface of the structured silicon wafer.

[0082] If the immersion time of t...

Embodiment 3

[0084] 1) Dilute γ-aminopropyltriethoxysilane and ethanol at a volume ratio of 1:150 to obtain solution a;

[0085] 2) Dilute the dispersion of silicon dioxide nanoparticles (~30nm, negatively charged) with a mass fraction of 70% and ethanol at a volume ratio of 1:150 to obtain solution b; take 200 μL of solution a and drop it into 30ml of solution b, that is obtaining nanoparticle coatings;

[0086] 3) At 90°C, vapor deposition of 20 mL of solution a onto the surface of cicada wings with irregular nanoscale structures;

[0087] 4) At room temperature, after immersing the cicada wings of the vapor deposition solution a in step (3) in the nanoparticle coating described in step (2) for 10 hours, take it out, rinse the surface with ethanol, and dry at room temperature to have irregular nano-scale A conformal, uniform thickness (approximately 200 nm) coating of silica nanoparticles formed on the surface of the structured cicada wings.

[0088] If the immersion time of the cicada...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com