Vermiculite composite filter aid with chain termination properties and preparation method thereof

A filter aid and chain termination technology, applied in the field of preparation of vermiculite composite filter aid, can solve the problems of complex polymerization termination process, large environmental pollution, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

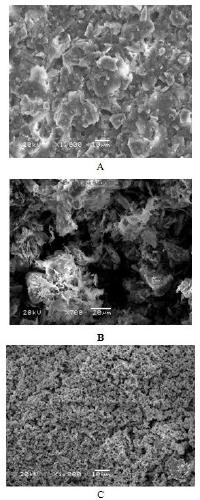

[0014] 1. Preparation of composite filter aid

[0015] Take 6g of hexamethylenetetramine, add it into 20mL of mixed solvent made of ethanol, n-butanol, and butyl acetate (10mL, 5mL, and 5mL for ethanol, n-butanol, and butyl acetate, respectively), and make a termination Liquid HMA;

[0016] Weigh 20g of vermiculite powder and 10g of kaolin, add them to the above stop solution, stir at 70-80°C for 5-6 hours, and grind to obtain the functional composite filter aid GN-HMA.

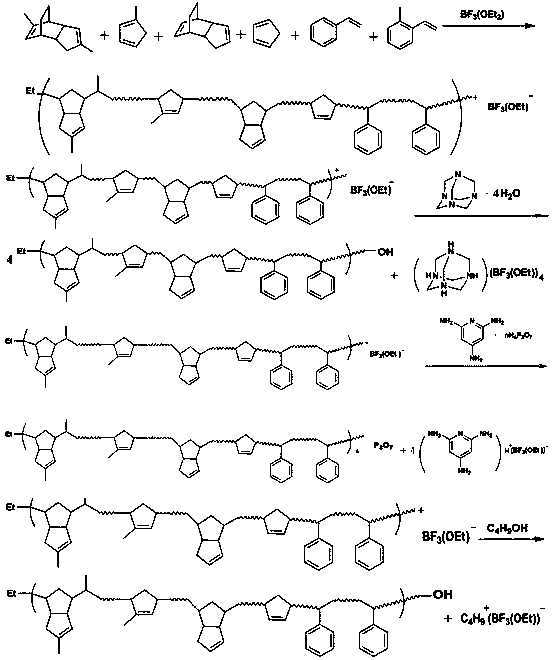

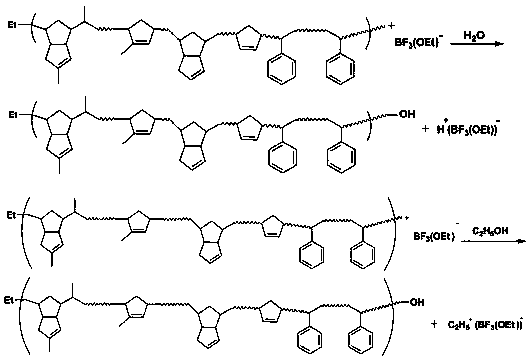

[0017] 2. Composite filter aid is used for termination and filtration of petroleum resin liquid

[0018] Weigh 500mL of ethylene cracking by-products into the reactor, add 5mL of boron trifluoride diethyl ether initiator dropwise at the polymerization temperature (30°C), the color of the system immediately changes from light yellow transparent liquid to maroon translucent liquid, accompanied by Rapid exothermic phenomenon, about 1 hour to complete the dropwise addition, and then keep the polymerization reac...

Embodiment 2

[0021] 1. Preparation of composite filter aid

[0022] Take 4g of hexamethylenetetramine and add it to 20mL of mixed solvent made of ethanol, n-butanol and butyl acetate (5mL, 10mL and 5mL of ethanol, n-butanol and butyl acetate respectively) to form Stop solution HMA;

[0023] Weigh 15g of vermiculite mineral powder and 15g of kaolin, add them to the above stop solution, stir at 70-80°C for 5-6 hours, and grind to obtain the functional composite filter aid GN-HMA.

[0024] 2. Composite filter aid is used for termination and filtration of petroleum resin liquid

[0025] Weigh 500mL of ethylene cracking by-products into the reactor, add 3mL of boron trifluoride diethyl ether initiator dropwise at the polymerization temperature (35°C), the color of the system immediately changes from light yellow transparent liquid to maroon translucent liquid, accompanied by Rapid exothermic phenomenon, about 1 hour to complete the dropwise addition, and then keep the polymerization reaction ...

Embodiment 3

[0028] 1. Preparation of composite filter aid

[0029] Take 8g of melamine pyrophosphate and add it to 30mL of a mixed solvent made of ethanol, n-butanol and butyl acetate (20mL, 5mL and 5mL for ethanol, n-butanol and butyl acetate respectively) to make a stop solution HMA ;

[0030] Weigh 12g of vermiculite mineral powder and 8g of kaolin, add them to the above stop solution, stir at 70-80°C for 5-6 hours, and grind to obtain the functional composite filter aid GN-HMA.

[0031] 2. Composite filter aid is used for termination and filtration of petroleum resin liquid

[0032] Weigh 500mL of ethylene cracking by-products into the reactor, add 7mL of boron trifluoride diethyl ether initiator dropwise at the polymerization temperature (25°C), the color of the system immediately changes from light yellow transparent liquid to maroon translucent liquid, accompanied by Rapid exothermic phenomenon, about 1 hour to complete the dropwise addition, and then keep the polymerization reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com