Compound manure fertilizer and preparation method thereof

A technology of farmyard manure and phosphate fertilizer, which is applied in the direction of urea compound fertilizer, nitrogen fertilizer, potassium fertilizer, etc., which can solve the problems of capillary roots that are easy to burn, difficulty in consistent fertilizer demand period, easy to cause root diseases and insect pests, etc., so as to facilitate application and transportation, avoid Long-term fermentation, fast onset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A flour fermented farmyard manure, comprising the following raw materials in parts by weight: 50 parts of human excrement, 30 parts of chicken manure, 10 parts of urea, 5 parts of phosphate fertilizer, 15 parts of vermiculite, 3 parts of camphor, 15 parts of humic acid, poppy shell 2 parts of powder, 3 parts of biological agent, 2 parts of chlorpyrifos, 2 parts of abamectin; 80 parts of auxiliary materials and 6 parts of decomposition accelerator.

[0034] The poppy husk powder is crushed and ground into powder by poppy husk, adding 3-5 times the weight of starch and 0.05-0.1 times the weight of iron powder;

[0035] Described decomposition accelerator is ferrous sulfate and calcium superphosphate that weight ratio is 1:10;

[0036] The cake fertilizer is sesame cake fertilizer;

[0037] Further, the biological agent is a mixture of Bacillus subtilis and Bacillus first, the total amount of which is 0.5-500 million / g.

[0038] The composition and parts by weight of the...

Embodiment 2

[0051] A fermented farmyard manure comprising the following raw materials in parts by weight: 60 parts of human excrement, 40 parts of chicken manure, 15 parts of urea, 10 parts of phosphate fertilizer, 20 parts of vermiculite, 5 parts of camphor, 20 parts of humic acid, poppy shell 3 parts of powder, 5 parts of biological agent, 3 parts of chlorpyrifos, 3 parts of abamectin; 100 parts of auxiliary materials and 10 parts of decomposition accelerator.

[0052] The poppy husk powder is crushed and ground into powder by poppy husk, and 5 times by weight of starch and 0.1 times by weight of iron powder are added; Calcium phosphate; the cake fertilizer is sesame cake fertilizer; the biological agent is a mixture of Bacillus subtilis and first Bacillus, the total number is 0.5-500 million / g;

[0053] The composition and parts by weight of the auxiliary materials are 20-30 parts of straw, 15-20 parts of corn cob, 10-15 parts of cake fertilizer, 10-15 parts of dead leaves, 8-10 parts ...

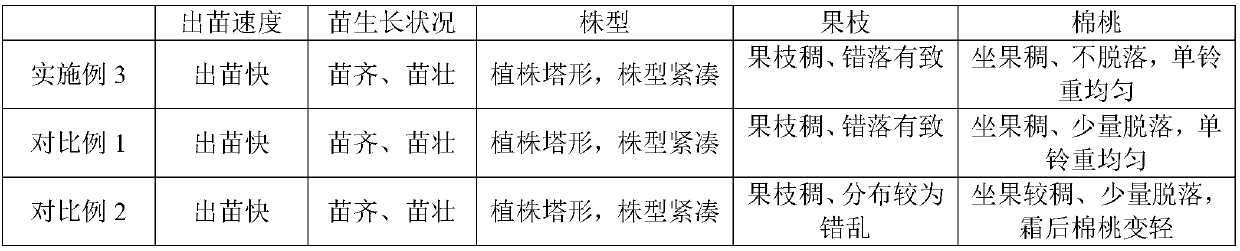

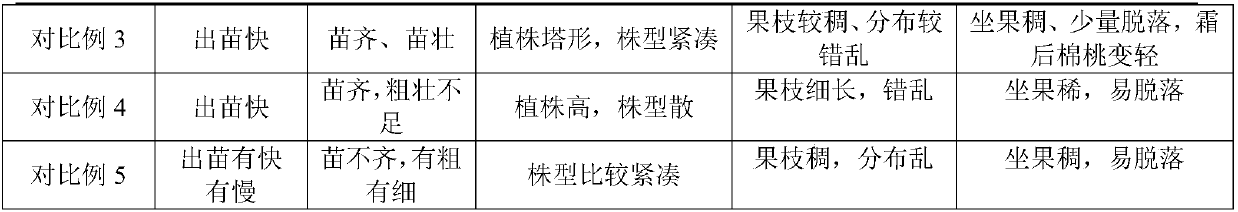

Embodiment 3

[0066] A fermented farmyard manure comprising the following raw materials by weight: 55 parts of human excrement, 35 parts of chicken manure, 12 parts of urea, 7 parts of phosphate fertilizer, 18 parts of vermiculite, 4 parts of camphor, 17 parts of humic acid, poppy shell 2.5 parts of powder, 4 parts of biological agent, 2.5 parts of chlorpyrifos, 2.5 parts of abamectin; 90 parts of auxiliary materials and 8 parts of decomposition accelerator.

[0067] The poppy husk powder is crushed and ground into powder by poppy husk, and 4 times of starch and 0.07 times of iron powder are added in parts by weight; Calcium phosphate; the cake fertilizer is sesame cake fertilizer; further, the biological agent is a mixed bacteria of Bacillus subtilis and Bacillus first, and the total number is 300 million / g.

[0068] The composition and parts by weight of the auxiliary materials are 25 parts of straw, 17 parts of corncobs, 12 parts of cake fertilizer, 12 parts of dead leaves, 9 parts of pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com