Mesoporous molecular sieve modified asphalt and preparation method thereof

A technology of mesoporous molecular sieve and modified asphalt, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of segregation and stratification of inorganic fillers and asphalt, physical migration and volatilization of anti-aging agents, and affecting anti-aging performance. Achieve the effects of improving anti-oxidation efficiency, improving anti-aging performance, and reducing high-temperature rutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

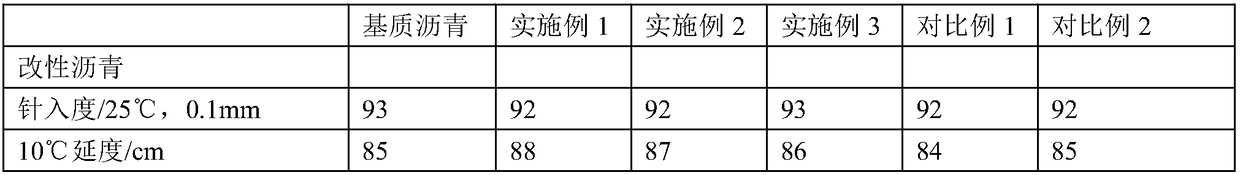

Examples

Embodiment 1

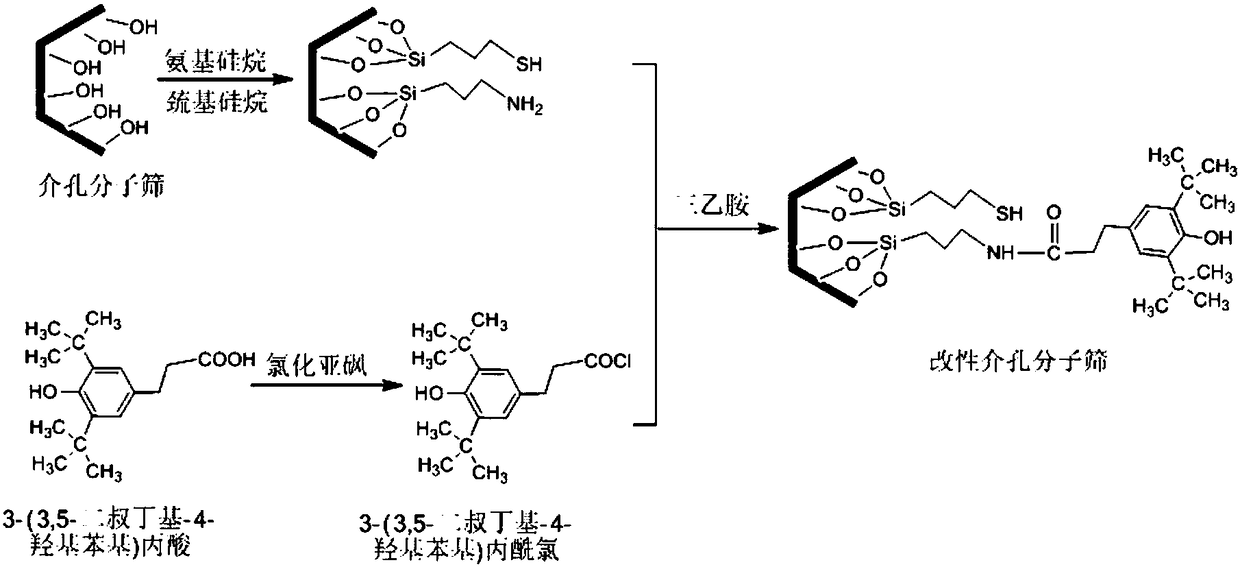

[0048] (1) 1 part by weight of MCM-41 mesoporous molecular sieve (specific surface area is 1000m 2 / g), account for MCM-41 mesoporous molecular sieve 15wt% 3-aminopropyltrimethoxysilane and account for MCM-41 mesoporous molecular sieve 4wt% gamma-mercaptopropyltrimethoxysilane join in 20 parts by weight of toluene . Keep the temperature at 110°C, keep stirring, heat and reflux for 3 hours, filter after cooling, wash with a large amount of ethanol, and dry at 100°C for 5 hours to obtain a mesoporous molecular sieve grafted with aminosilane and mercaptosilane.

[0049] (2) Under nitrogen protection, 1 weight part of 3-(3,5-di-tert-butyl-4-hydroxyphenyl)acrylic acid and 1.4 weight part of thionyl chloride were added to 30 weight parts of chloroform at 50°C Heating and reacting for 8 hours, and distilling under reduced pressure to obtain 3-(3,5-di-tert-butyl-4-hydroxyphenyl)acryloyl chloride.

[0050] (3) Add 1 part by weight of mesoporous molecular sieve grafted with aminosilan...

Embodiment 2

[0053] (1) 1 part by weight of SBA-15 mesoporous molecular sieve (specific surface area is 1100m 2 / g), account for 3-aminopropyltriethoxysilane of SBA-15 mesoporous molecular sieve 10wt%, and account for the gamma-mercaptopropyl triethoxysilane of SBA-15 mesoporous molecular sieve 6wt% to join in 20 parts by weight in toluene. Keep the temperature at 110°C, keep stirring, heat and reflux for 3 hours, filter after cooling, wash with a large amount of ethanol, and dry at 100°C for 5 hours to obtain a mesoporous molecular sieve grafted with aminosilane and mercaptosilane.

[0054] (2) Under the protection of nitrogen, 1 part by weight of 3,5-di-tert-butyl-4-hydroxybenzoic acid and 1.3 parts by weight of thionyl chloride were added to 25 parts by weight of chloroform, heated at 50°C for 8 hours, and the Pressure distillation to obtain 3,5-di-tert-butyl-4-hydroxybenzoyl chloride.

[0055] (3) Add 1 part by weight of mesoporous molecular sieve grafted with aminosilane and mercapt...

Embodiment 3

[0058] (1) 1.5 parts by weight of SBA-16 mesoporous molecular sieve (specific surface area is 900m 2 g), account for γ-aminopropylmethyldiethoxysilane of SBA-16 mesoporous molecular sieve 5wt%, and account for γ-mercaptopropylmethyldiethoxysilane of SBA-16 mesoporous molecular sieve 10wt% add To 20 parts by weight of toluene. Keep the temperature at 110°C, keep stirring, heat and reflux for 3 hours, filter after cooling, wash with a large amount of ethanol, and dry at 100°C for 5 hours to obtain a mesoporous molecular sieve grafted with aminosilane and mercaptosilane.

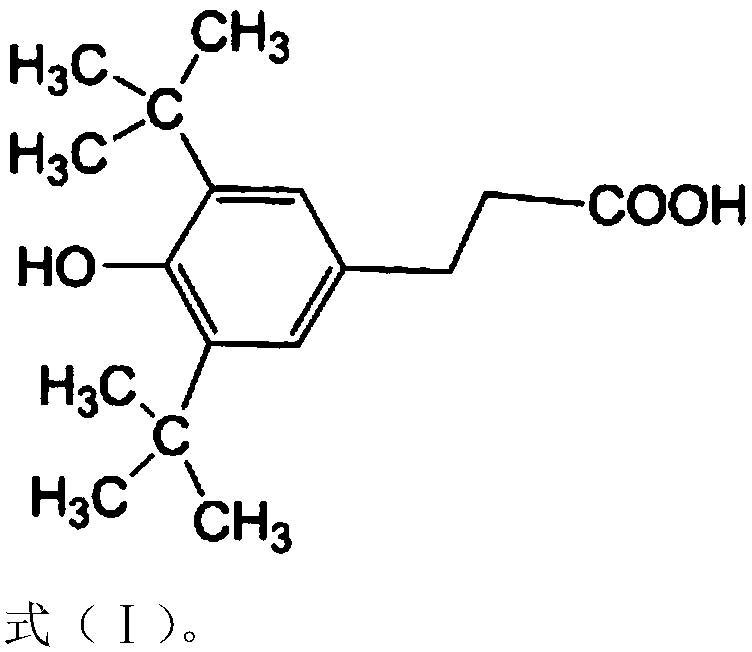

[0059] (2) Under nitrogen protection, 1 part by weight of 3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid and 1.2 parts by weight of thionyl chloride were added to 25 parts by weight of chloroform, 50 The reaction was heated at ℃ for 7h, and then distilled under reduced pressure to obtain 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl chloride.

[0060] (3) 1.5 parts by weight of mesoporous molecular sie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com