Photosensitive solder resist white ink, LED circuit board and preparation method

A technology of LED circuit board and white ink, which is used in ink, printed circuit manufacturing, circuit mask manufacturing, etc., can solve the problems of high raw material cost of photosensitive solder resist white ink, insufficient temperature resistance of resin, darkening of color, etc. Good photoinitiation efficiency, excellent high temperature resistance and sufficient hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

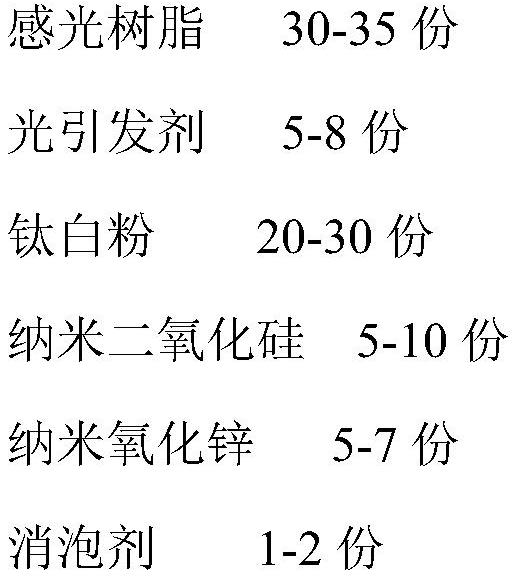

[0048] A kind of photosensitive solder resist white ink of the present embodiment comprises following components:

[0049]

[0050] The titanium dioxide is composed of rutile type titanium dioxide and anatase type titanium dioxide according to the mass ratio of 4:1;

[0051] The particle size of the titanium dioxide is 5-10 μm.

Embodiment 2

[0053]

[0054] The titanium dioxide is composed of rutile type titanium dioxide and anatase type titanium dioxide according to the mass ratio of 4:1;

[0055] The particle size of the titanium dioxide is 5-10 μm.

Embodiment 3

[0057]

[0058] The titanium dioxide is composed of rutile type titanium dioxide and anatase type titanium dioxide according to the mass ratio of 4:1;

[0059] The particle size of the titanium dioxide is 5-10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com