Silicon-based lithium ion battery negative electrode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor conductivity, low structural stability, and low cycle life, and achieve improved battery life, high capacity, and stable materials structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

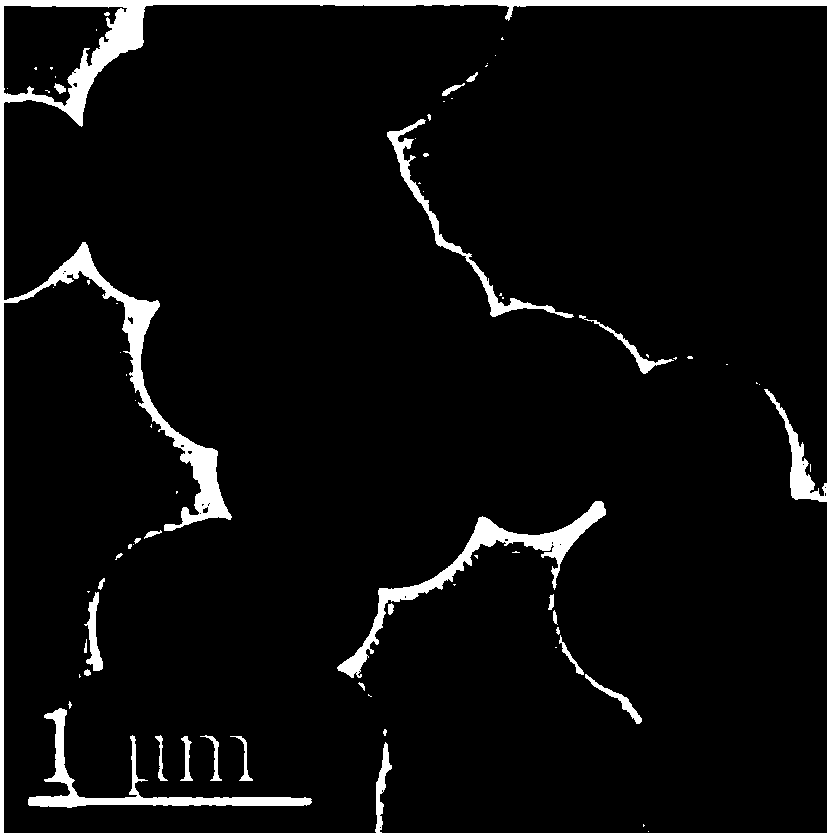

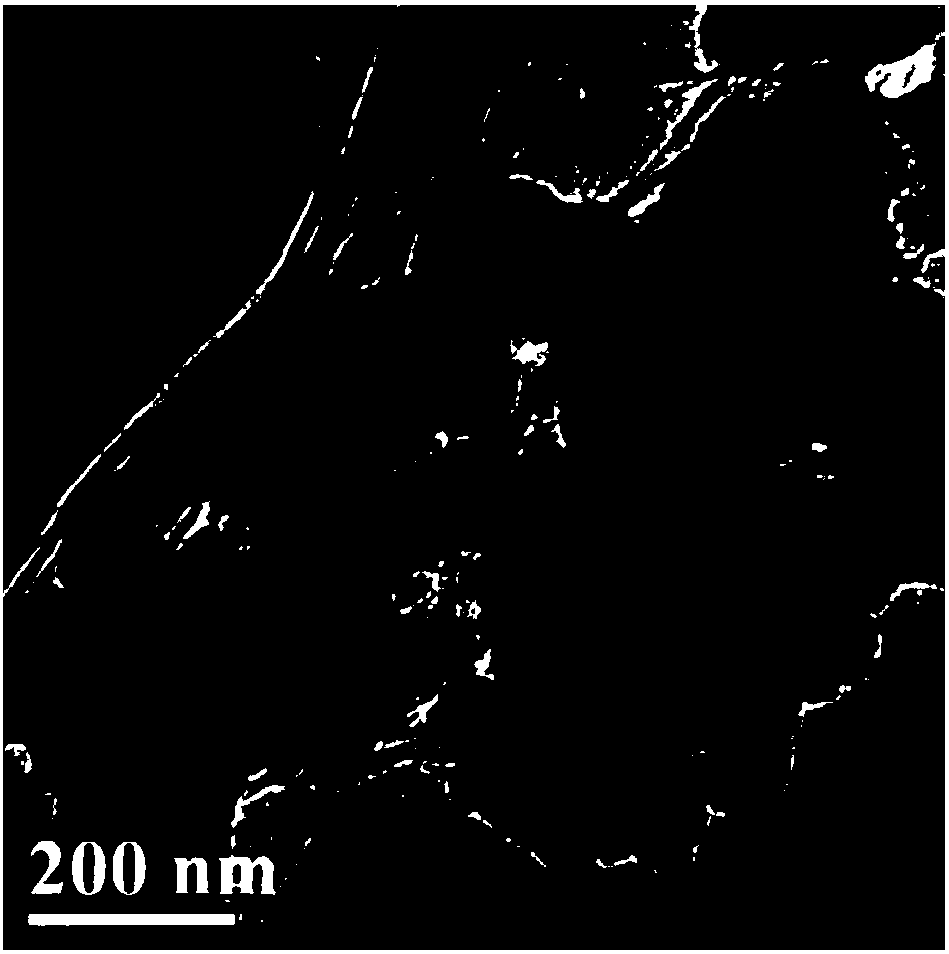

[0029] (1) Take 1 g of nano-spherical zinc oxide particles with a particle size of 200 nm and disperse them in a mixed solution of 50 mL of water and ethanol to form a nano-zinc oxide dispersion. Then slowly add 1 g of tetraethyl orthosilicate into the above-mentioned nano-zinc oxide dispersion liquid, and stir while adding. After all the tetraethyl orthosilicate was added, 5 mL of concentrated ammonia water was added, stirred for 30 minutes, centrifuged, washed, and the obtained precipitate was dried. Then place the precipitate in a muffle furnace and heat it to 120°C for 1 hour to obtain ZnO / SiO with a core-shell structure. 2 ;

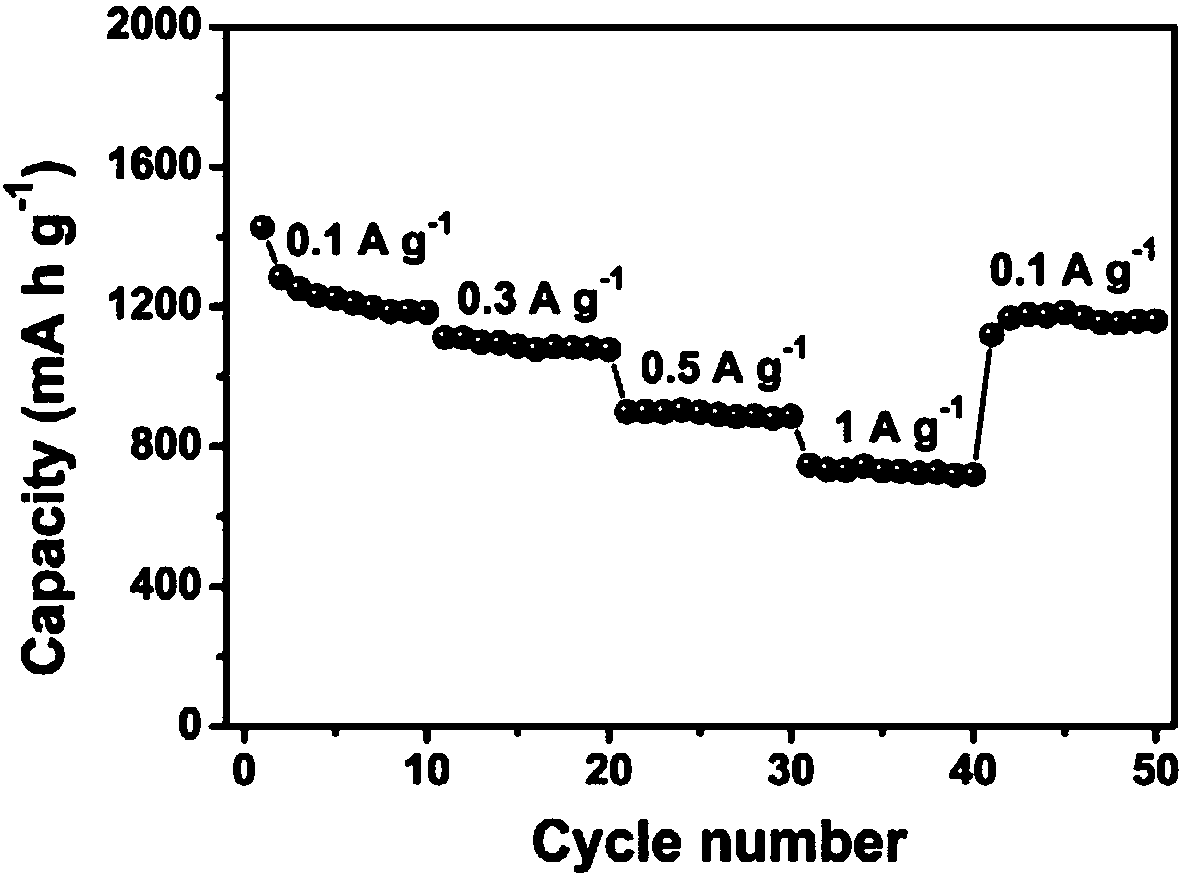

[0030] (2) Take the above-mentioned ZnO / SiO with core-shell structure 2 Mix it with zinc powder at a mass ratio of 1:4, and heat at 650°C for 3 hours in a tube furnace under the protection of nitrogen atmosphere. After the reaction, the silicon-based material ZnO / SiO with lithium storage activity is obtained x (The following uses ZnO / SiO x Indi...

Embodiment 2

[0037] (1) Take 1 g of nano-spherical zinc oxide particles with a particle size of 10 nm and disperse them in a mixed solution of 50 mL of water and ethanol to form a nano-zinc oxide dispersion. Then slowly add 3 g of tetramethyl orthosilicate into the above-mentioned nano-zinc oxide dispersion liquid, and stir while adding. After all the tetramethyl orthosilicate was added, 5 mL of concentrated ammonia water was added, stirred for 30 minutes, centrifuged, washed, and the obtained precipitate was dried. Then place the precipitate in a muffle furnace and heat it to 100°C for 1.5h to obtain ZnO / SiO with a core-shell structure 2 ;

[0038] (2) Take the above-mentioned ZnO / SiO with core-shell structure 2 Mix it with zinc powder at a mass ratio of 1:3, and heat at 750°C for 6 hours in a tube furnace under the protection of a nitrogen atmosphere. After the reaction, the silicon-based material ZnO / SiO with lithium storage activity is obtained x (The following uses ZnO / SiO x Indi...

Embodiment 3

[0045] (1) Take 1 g of nano-spherical zinc oxide particles with a particle size of 30 nm and disperse them in a mixed solution of 50 mL of water and ethanol to form a nano-zinc oxide dispersion. Then, 1.5 g of tetrabutyl orthosilicate was slowly added into the above-mentioned nano-zinc oxide dispersion liquid, and stirred while adding. After all the tetrabutyl orthosilicate was added, 5 mL of concentrated ammonia water was added, stirred for 30 minutes, centrifuged, washed, and the obtained precipitate was dried. Then place the precipitate in a muffle furnace and heat it to 60°C for 1 hour to obtain ZnO / SiO with a core-shell structure. 2 ;

[0046] (2) Take the above-mentioned ZnO / SiO with core-shell structure 2 Mix it with zinc powder at a mass ratio of 1:3, and heat at 850°C for 3 hours in a tube furnace under a nitrogen-protected atmosphere. After the reaction, the silicon-based material ZnO / SiO with lithium storage activity is obtained x (The following uses ZnO / SiO x ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com