Gradient composite material and preparation method and application thereof

A composite material, gradient technology, applied in the fields of medical science, prosthesis, tissue regeneration, etc., to achieve the effect of controllable process, good hydrophilicity, and small surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In the first aspect, the present invention provides a method for preparing a gradient composite material. The method includes the following steps:

[0033] (1) Using organic solvents to formulate biocompatible polymers and bioactive ceramic powder into a variety of slurries with different contents of bioactive ceramic powder; and

[0034] (2) The multiple slurries prepared in step (1) are cast layer by layer or co-pressed by layered casting in a manner of increasing or decreasing bioactive ceramic powder content to obtain a gradient composite containing multilayer casting film material.

[0035] In the present invention, the multiple refers to two or more than two, the multi-layer refers to two and more than two layers; the layer-by-layer casting refers to placing a certain volume of a slurry Casting in the casting machine to obtain the first layer of cast film, and then on the basis of the first layer of cast film, another slurry is placed in the casting machine for casting ...

Embodiment 1

[0057] ①Mix the polycaprolactone and calcium silicophosphate powder in four 50mL sealed bottles according to different volume ratios of 1:0, 7:3, 5:5 and 3:7, and then put them into each sealed bottle Add a certain amount of dichloromethane to dissolve the polycaprolactone, and after the polycaprolactone is completely dissolved, 4 kinds of slurries with different volume percentages of uniformly dispersed calcium silicophosphate are obtained.

[0058] ②The 4 kinds of slurries obtained in ① were used for layered casting using the preparation parameters in Table 1 to prepare 4 kinds of single-layer casting films with increasing volume percentage of calcium silicophosphate. In Table 1, the casting volume indicates the amount of each slurry used for casting.

[0059] Perform performance tests on the four single-layer cast films prepared in this example:

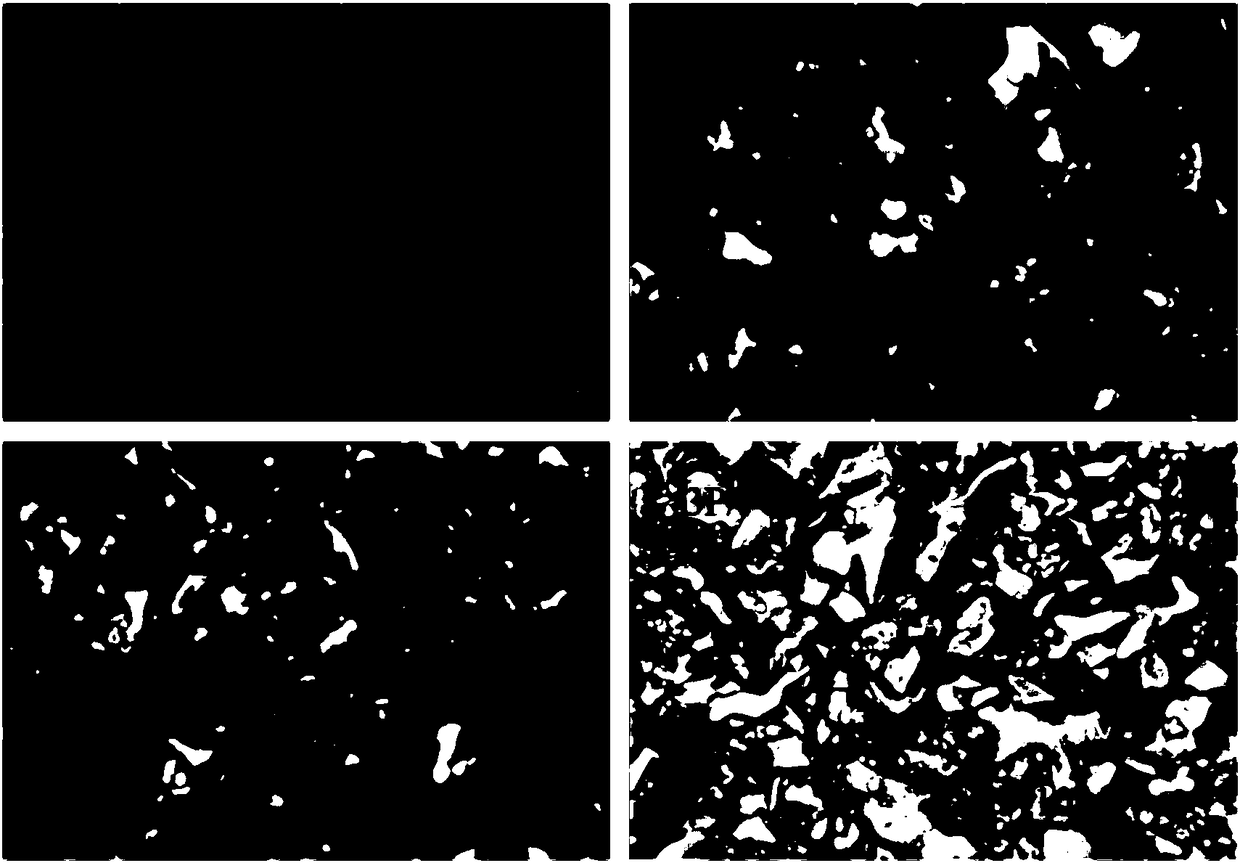

[0060] figure 1 The backscattered surface topography (SEM image) of the four single-layer cast films prepared in this example. by fig...

Embodiment 2

[0062] The adhesion experiments of mouse osteoblasts and fibroblasts were carried out on the 4 kinds of cast monolayer films obtained in Example 1. After each sample of monolayer cast film was sterilized by 75% alcohol for 2 hours, the density was 5×10 4 Cells / mL 1mL of cell suspension was inoculated on the surface of the sample. After culturing for a specific time (1, 4, 24h), wash each monolayer cast film sample twice with phosphate buffered saline solution (PBS buffer), and use the mass fraction Fix the cells with 4% paraformaldehyde, wash with PBS buffer, add 500 μL volume of 0.1% Triton 100 for cell permeabilization, and finally use rhodamine dye and 4,6-diamidine- 2-Phenylindole (DAPI) stains the cytoskeleton and nucleus of the cells, and observes the cytoskeleton and nucleus under a fluorescence microscope.

[0063] figure 2 The experimental results of the morphology observation of osteoblasts on the surface of the four single-layer cast film samples of this example. by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com