Controlled preparation method of three-dimensional honeycomb-structured ZnO nano-material

A technology of honeycomb structure and nanomaterials, which is applied in the field of controllable preparation of three-dimensional honeycomb structure zinc oxide nanomaterials, can solve the problem that the requirements of high-performance gas sensing and catalytic materials cannot be met, the honeycomb scale is not suitable for flexible control, and the scale of honeycomb ZnO is large and other problems, to achieve the effect of improving gas sensitivity and photocatalytic performance, strong surface activity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

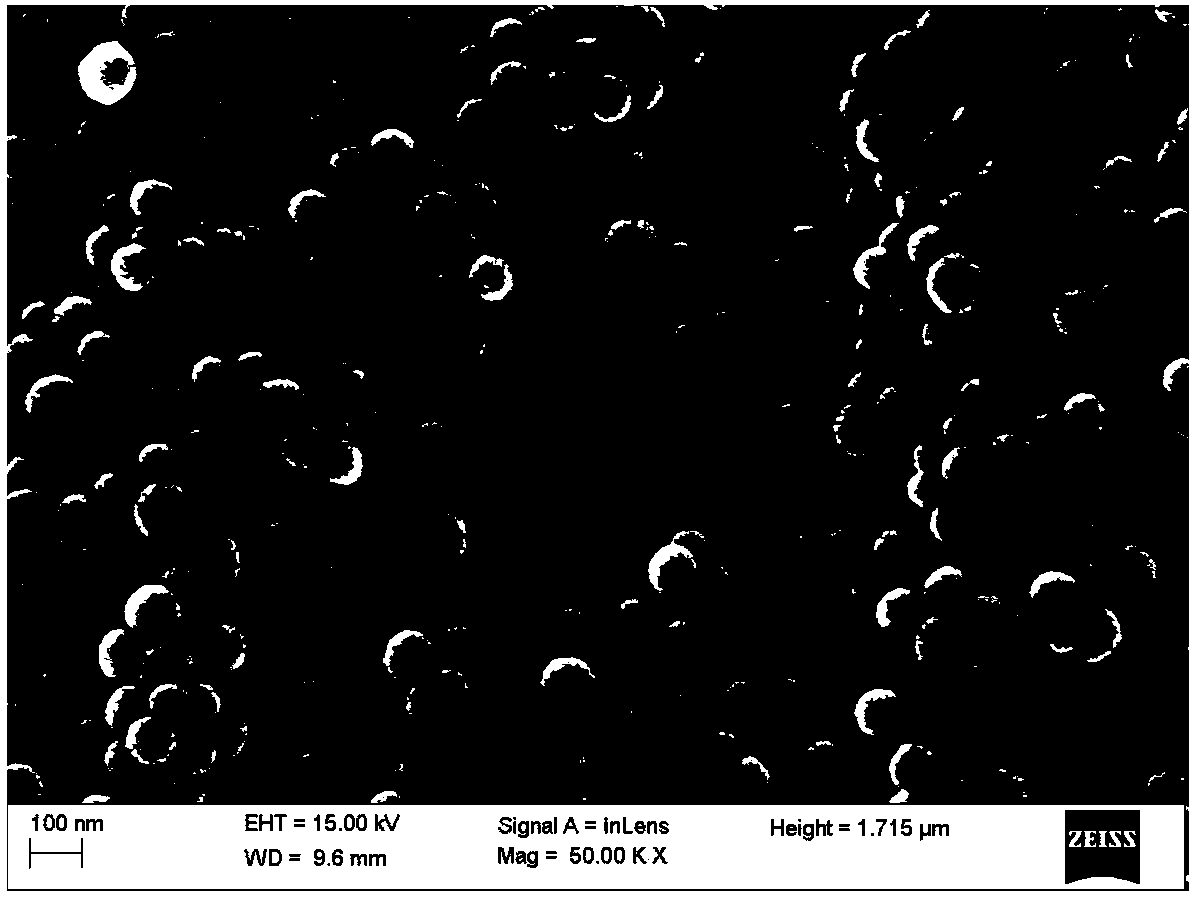

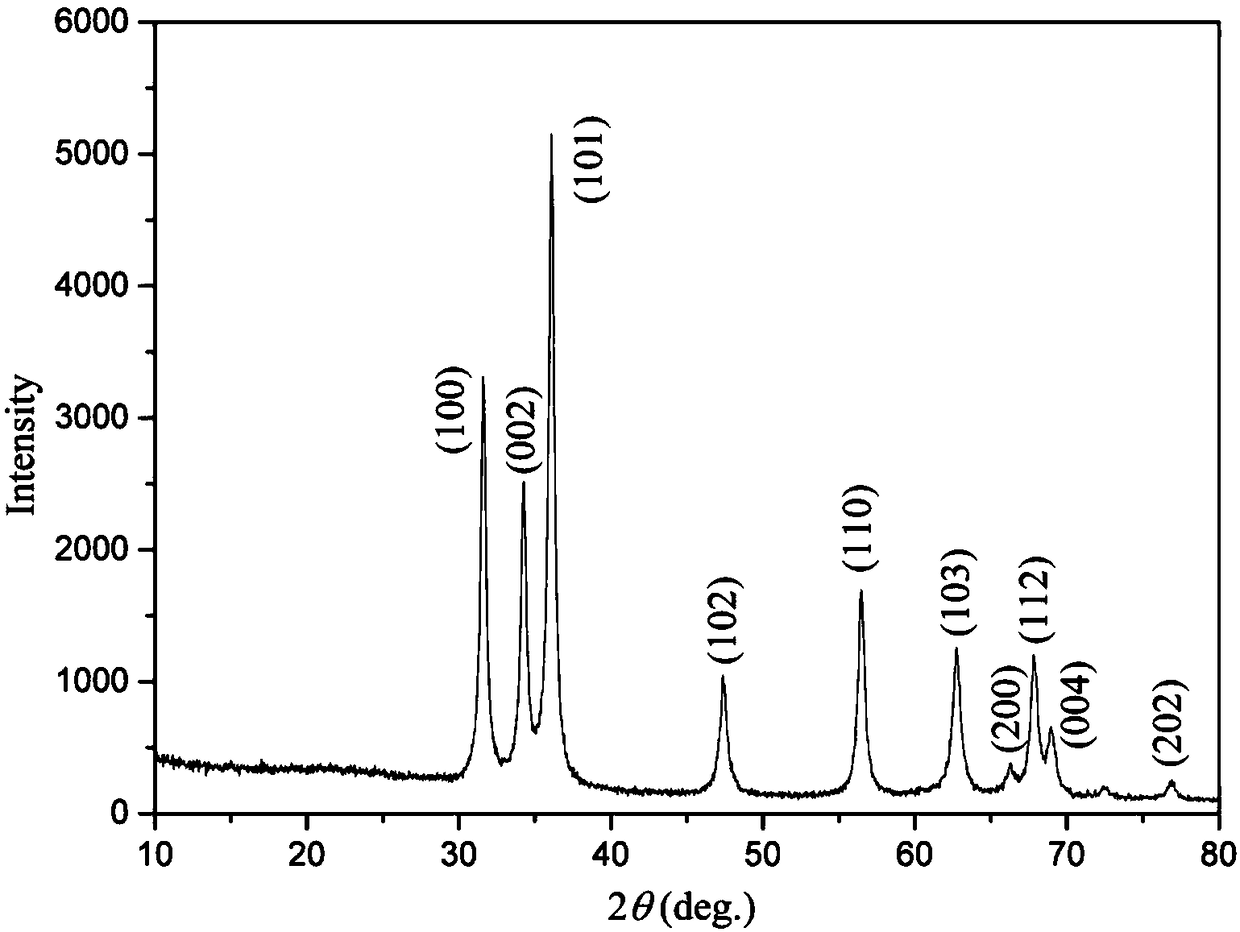

[0031] A controllable preparation method of a three-dimensional honeycomb structure ZnO nanomaterial, comprising the following steps:

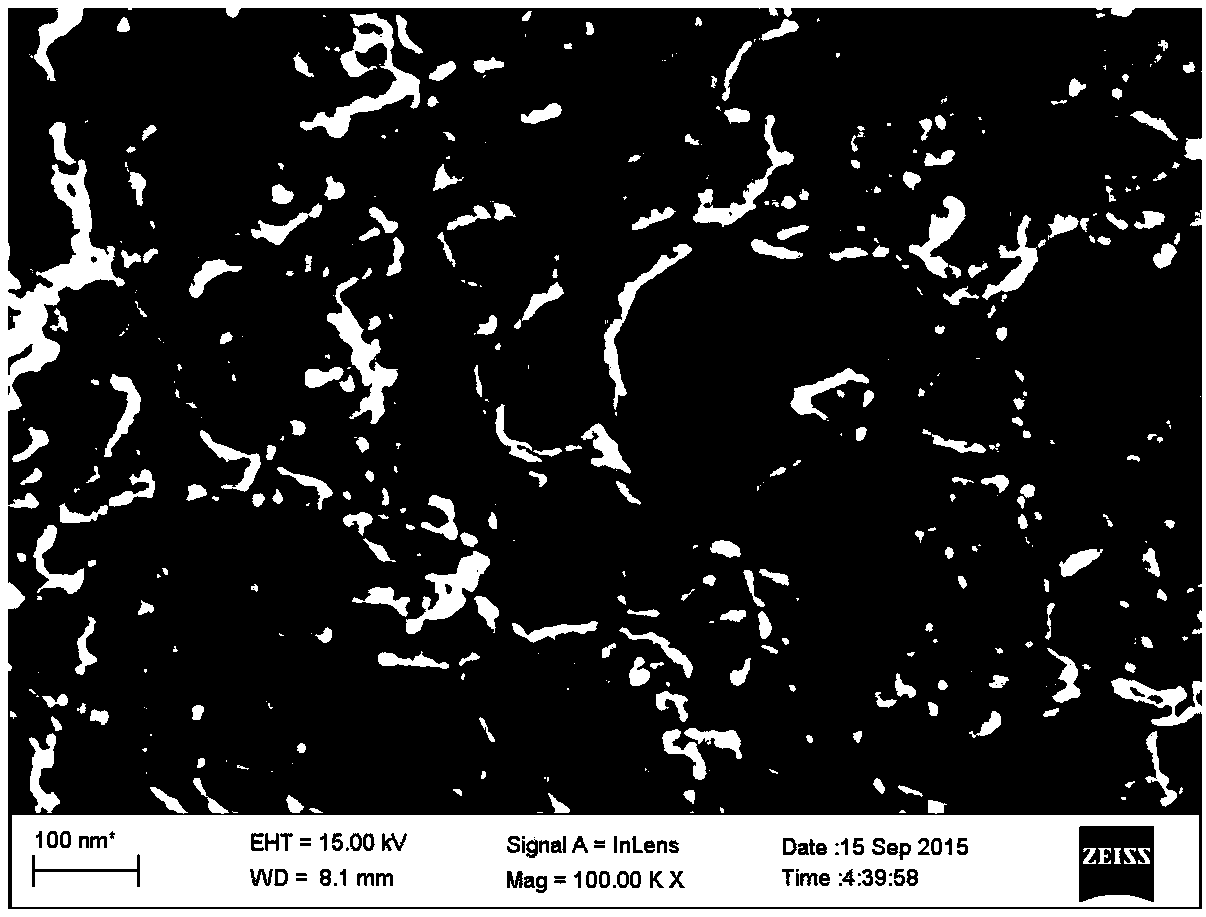

[0032] Step 1. Dissolve glucose in deionized water to prepare a glucose solution with a concentration of 0.5mol / L; transfer it to a hydrothermal reaction kettle and react at 180°C for 4 hours; after cooling, wash and dry at 60°C. Uniform and well-dispersed carbon nanospheres with a particle size of about 80nm were obtained; figure 2 The scanning electron micrograph of the carbon nanospheres prepared in Example 1;

[0033] Step 2. Soak the carbon nanospheres in step 1 in deionized water at a solid-to-liquid mass ratio of 1:30 to obtain a coating reaction bottom solution; adjust the pH value of the coating reaction bottom solution to 5.6 with acetic acid;

[0034] Step 3. Slowly drop 100 mL of zinc acetate solution with a concentration of 1 mol / L and dilute ammonia water with a mass concentration of 7% into the coating reaction bottom solution...

Embodiment 2

[0037] A controllable preparation method of a three-dimensional honeycomb structure ZnO nanomaterial, comprising the following steps:

[0038] Step 1. Dissolve glucose in deionized water to prepare a glucose solution with a concentration of 0.25mol / L; transfer it to a hydrothermal reaction kettle and react at 160°C for 4 hours; after cooling, wash and dry at 60°C. Uniform and well-dispersed carbon nanospheres with a particle size of about 60nm were obtained;

[0039] Step 2. Soak the carbon nanospheres in step 1 in deionized water at a solid-to-liquid mass ratio of 1:40 to obtain a coating reaction bottom solution; adjust the pH value of the coating reaction bottom solution to 6.0 with acetic acid;

[0040] Step 3. Slowly drop 100 mL of zinc acetate solution with a concentration of 0.5 mol / L and dilute ammonia water with a mass concentration of 5% into the coating reaction bottom solution in step 2 at the same time at a rate ratio of 5:1 to control the reaction pH value 6.0 a...

Embodiment 3

[0043] A controllable preparation method of a three-dimensional honeycomb structure ZnO nanomaterial, comprising the following steps:

[0044] Step 1. Dissolve sucrose in deionized water to prepare a sucrose solution with a concentration of 1mol / L; transfer it to a hydrothermal reaction kettle and react at 200°C for 5 hours; after cooling, wash and dry at 60°C to prepare Uniform and well-dispersed carbon nanospheres with a particle size of about 90nm were obtained;

[0045] Step 2. Soak the carbon nanospheres in step 1 in deionized water at a solid-to-liquid mass ratio of 1:50 to obtain a coating reaction bottom solution; adjust the pH value of the coating reaction bottom solution to 6.5 with acetic acid;

[0046] Step 3. Slowly drop 100 mL of zinc acetate solution with a concentration of 1 mol / L and dilute ammonia water with a mass concentration of 10% into the coating reaction bottom solution in step 2 at the same time at a rate ratio of 3:1, and control the reaction pH to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com