Cuprous oxide-metal organic frame composite material and preparation method thereof

A technology of metal-organic framework and cuprous oxide, which is applied in the field of Cu2O-MOFs composite materials and its preparation, can solve the problems of limiting large-scale industrial application and lack of stability, and achieves low production cost, environmentally friendly preparation process and excellent preparation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

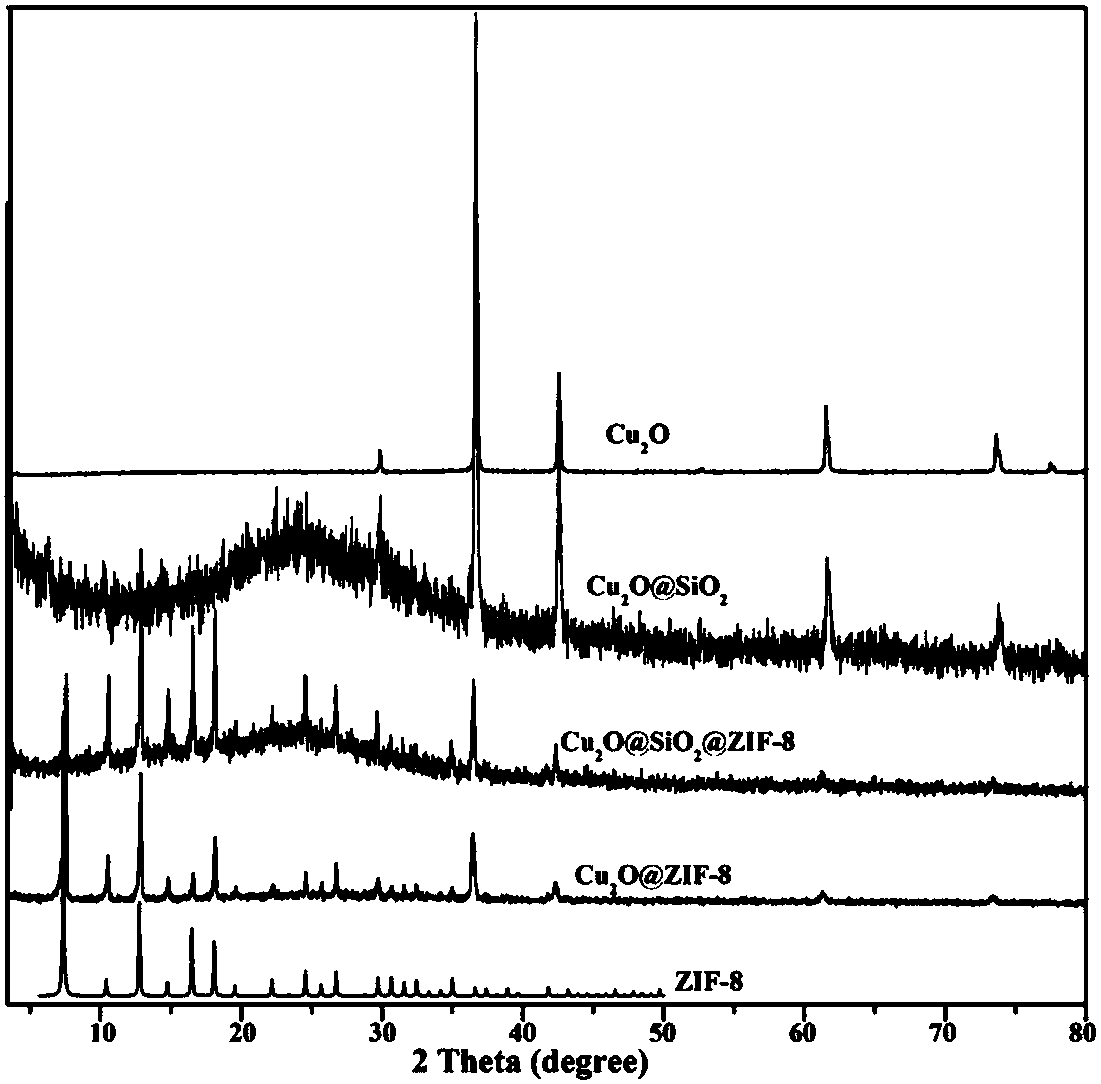

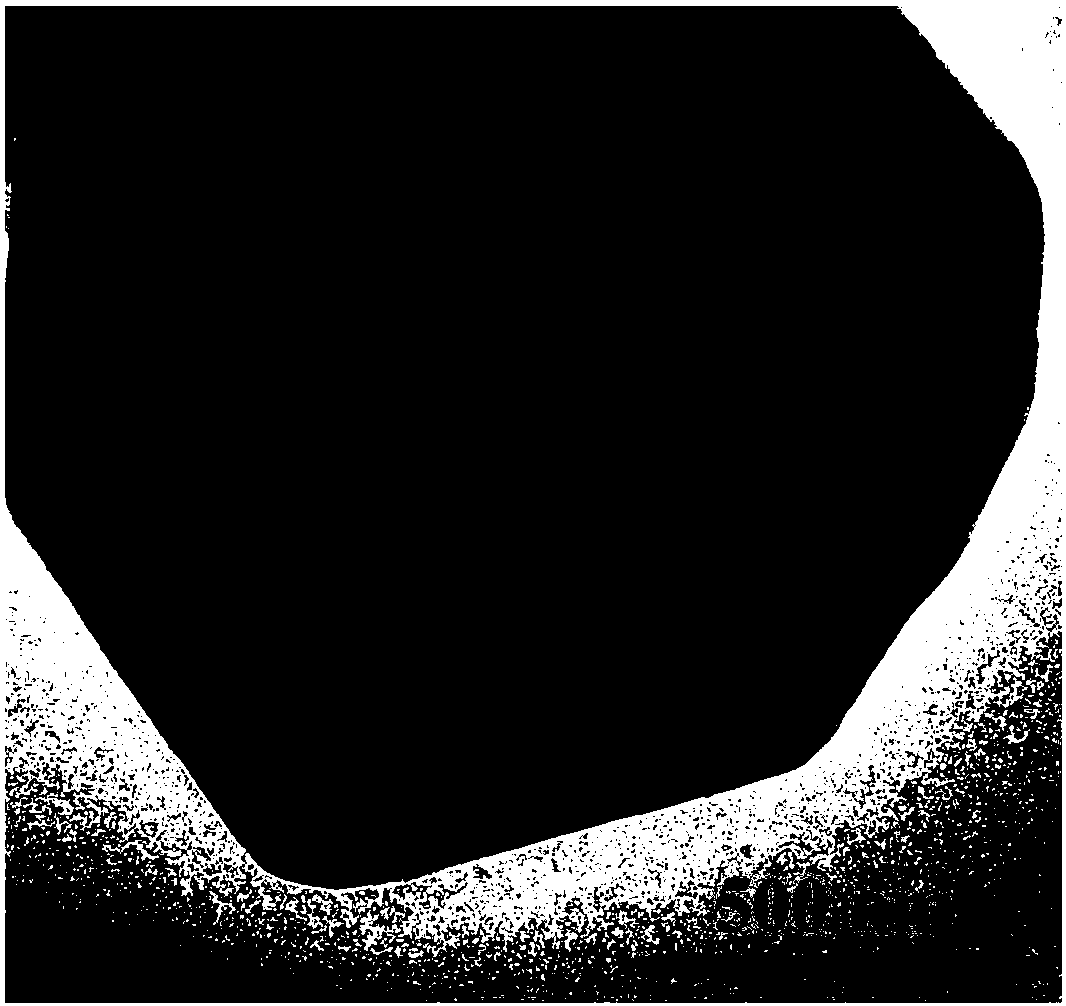

[0025] A Cuprous Oxide-Metal Organic Framework Cu 2 The preparation method of O@ZIF-8 composite material specifically includes the following steps:

[0026] (1), preparation of cuprous oxide nanoparticles (Cu 2 O);

[0027] Mix 5mL of copper chloride aqueous solution with a concentration of 0.08mol / L and 87mL of sodium lauryl sulfate solution with a concentration of 0.027mol / L, place the container in a water bath at 30-35°C for 20min, and under ultrasonic conditions Next, add 16.5 mL of NaOH solution with a concentration of 0.08 mol / L to the mixed solution, continue to sonicate for 10 minutes, add 3.5 mL of hydroxylamine hydrochloride solution with a concentration of 0.08 mol / L to the above mixed solution within 20 seconds, and continue to sonicate for 1 hour; The resulting reaction solution was centrifuged to remove the supernatant, and washed several times with water / absolute ethanol solution and absolute ethanol with a volume ratio of 1:1, and finally obtained a mass conc...

Embodiment 2

[0035] A Cuprous Oxide-Metal Organic Framework Cu 2 The preparation method of O@ZIF-8 composite material specifically includes the following steps:

[0036] (1), preparation of cuprous oxide nanoparticles (Cu 2 O);

[0037] Mix 8mL of copper chloride aqueous solution with a concentration of 0.08mol / L and 110mL of sodium lauryl sulfate solution with a concentration of 0.035mol / L, and place the container in a water bath at 30-35°C for 20 minutes to sonicate. Next, add 23mL of NaOH solution with a concentration of 0.1mol / L to the mixed solution, continue to sonicate for 10min, add 5.1mL of hydroxylamine hydrochloride solution with a concentration of 0.08mol / L to the above mixed solution within 20s, and continue to sonicate for 1 hour; The resulting reaction solution was centrifuged to remove the supernatant, and washed several times with water / dehydrated ethanol solution and absolute ethanol with a volume ratio of 1:1, and finally obtained a mass concentration of 8 mL and a con...

Embodiment 3

[0045] A Cuprous Oxide-Metal Organic Framework Cu 2 The preparation method of O@ZIF-8 composite material specifically includes the following steps:

[0046] (1), preparation of cuprous oxide nanoparticles (Cu 2 O);

[0047] Mix 10mL of copper chloride aqueous solution with a concentration of 0.1mol / L and 153mL of sodium lauryl sulfate solution with a concentration of 0.04mol / L, and place the container in a water bath at 30-35°C for 20 minutes to sonicate. Next, add 32.5 mL of NaOH solution with a concentration of 0.12 mol / L to the mixed solution, continue to sonicate for 10 minutes, add 7.5 mL of hydroxylamine hydrochloride solution with a concentration of 0.12 mol / L to the above mixed solution within 20 seconds, and continue to sonicate for 1 hour; The resulting reaction solution was centrifuged to remove the supernatant, and washed several times with water / absolute ethanol solution and absolute ethanol with a volume ratio of 1:1, and finally obtained a mass concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com