Resource regeneration method for hazardous waste

A hazardous waste and resource regeneration technology, applied in the direction of improving process efficiency, can solve problems such as complicated operation, clogged tuyere, poor adaptability, etc., and achieve the effect of high metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention can be further described through the following examples, but they are not intended to limit the protection scope of the claims of the present invention.

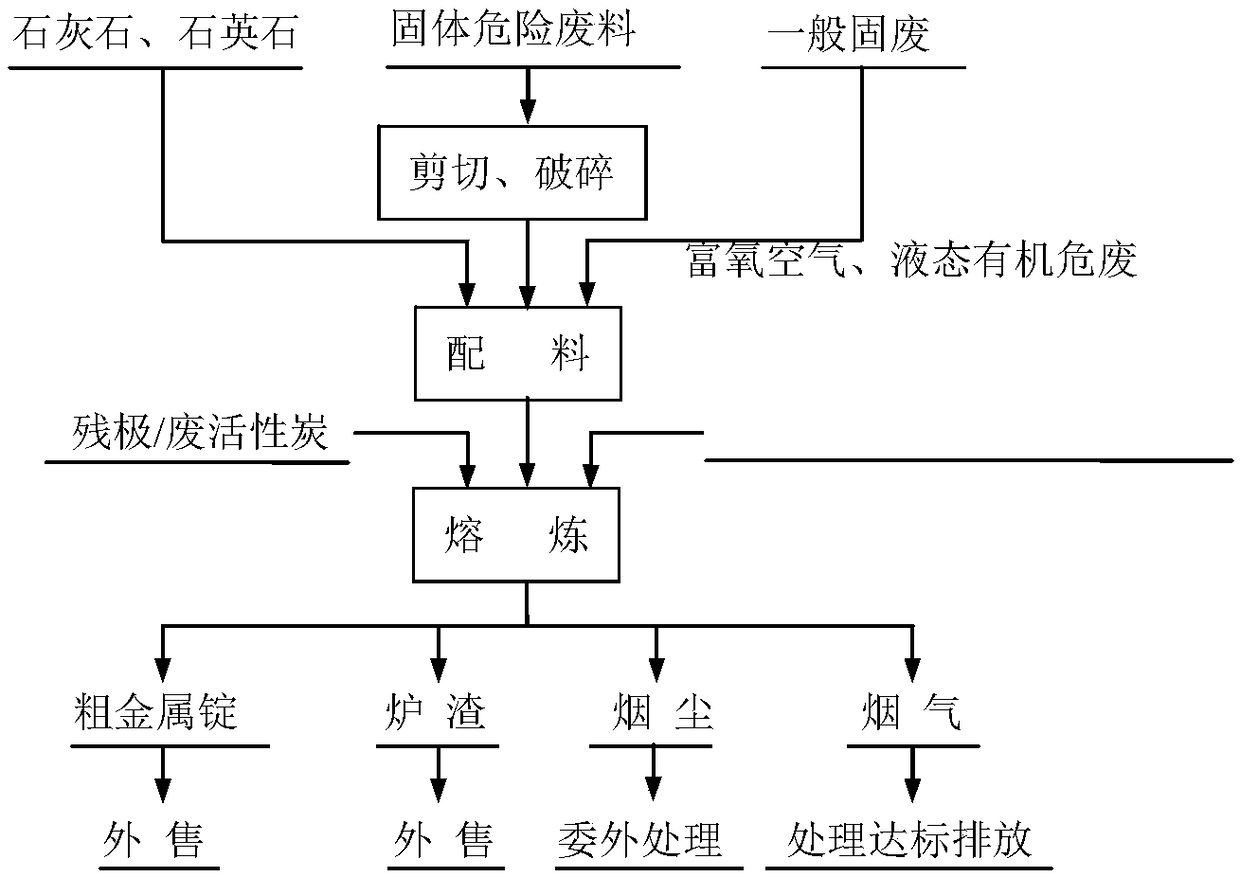

[0023] The resource regeneration method of a hazardous waste provided by the present invention can simultaneously process three types of hazardous wastes: valuable solid hazardous waste (metal solid hazardous waste with a metal content greater than 3%), liquid organic hazardous waste, and waste activated carbon / residual poles. Mainly use metal-containing solid hazardous waste (such as surface treatment waste HW17, copper-containing waste HW22, waste circuit board HW49, waste catalyst HW50, non-ferrous metal smelting waste HW48, etc.) Hazardous waste (such as waste mineral oil and waste containing mineral oil HW08, waste organic solvent and waste containing organic solvent HW06 in the National Hazardous Waste List) is used as auxiliary fuel, and waste activated carbon (HW49) or residual pole (HW48,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com