Preparation method for sintered neodymium iron boron permanent magnet free of heavy rare earths

A neodymium-iron-boron and permanent magnet technology, applied in the direction of magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of low distribution uniformity of neodymium-rich grain boundary phase, increased labor intensity, labor cost, grain boundary phase Uneven distribution, etc., to achieve the effect of being conducive to continuous extraction, shortening sintering time, and preventing the formation of tiny pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

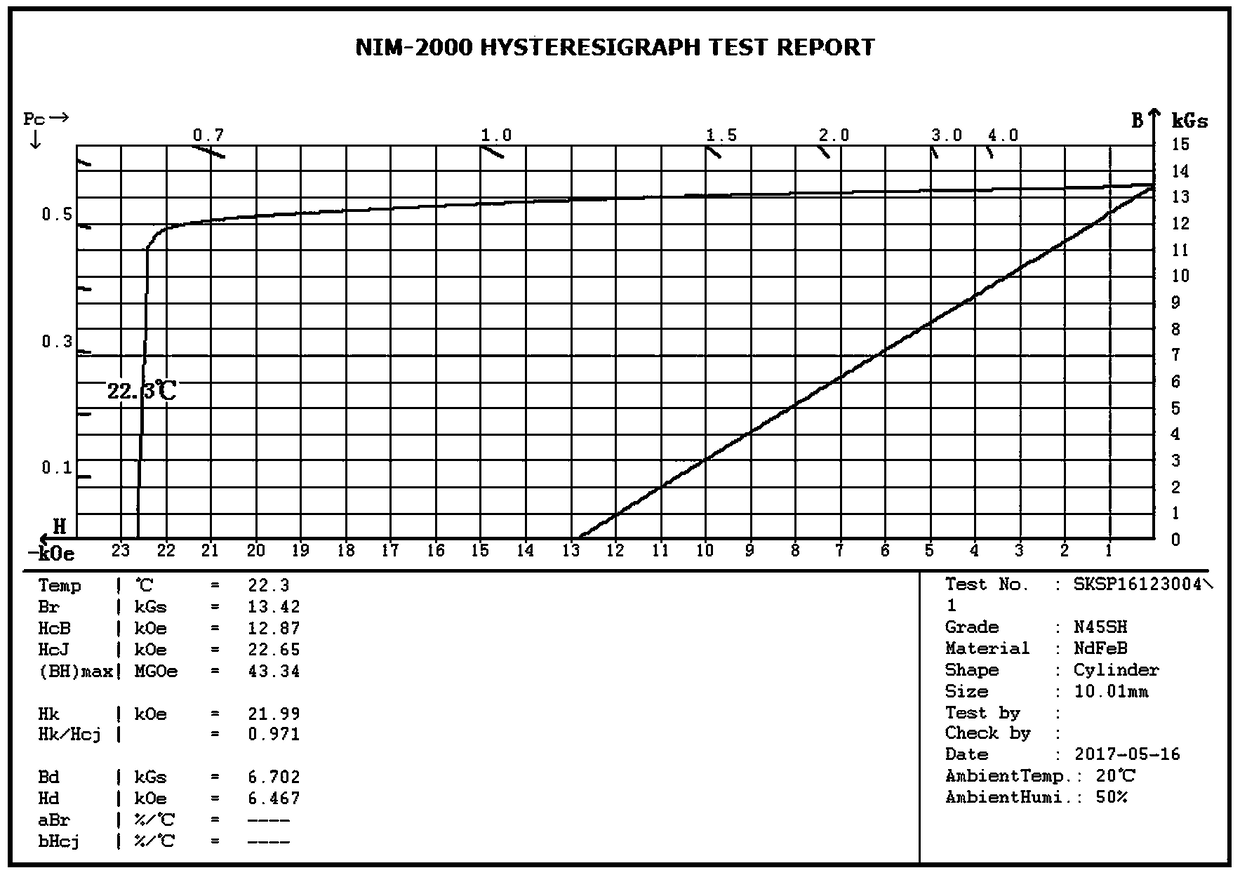

Embodiment 1

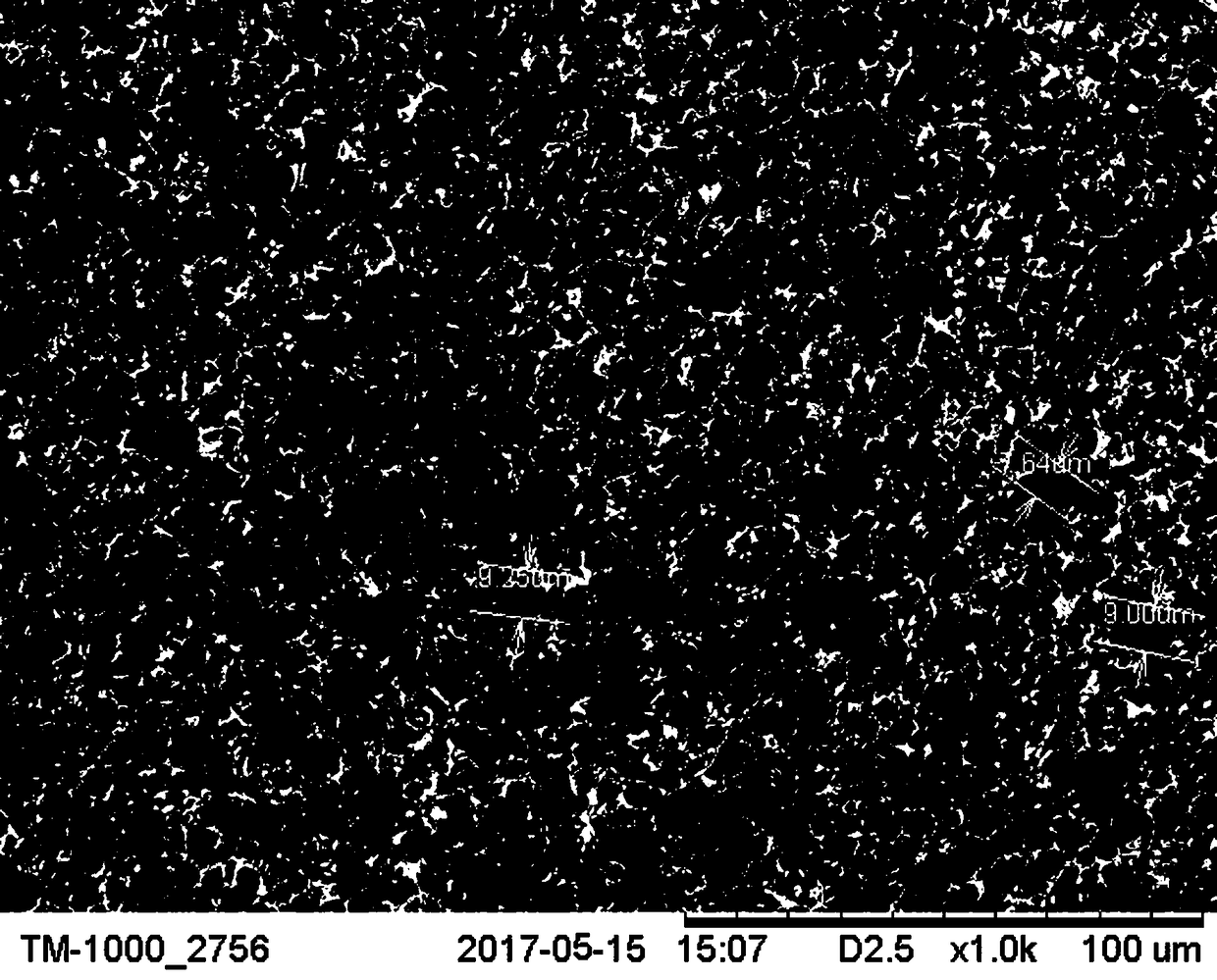

[0022] (a) The sintered NdFeB permanent magnet raw materials are based on weight percentage, Pr25Nd75 is 31.5wt%; B is 0.83wt%; Co is 1.0wt%; Al is 0.3wt%; Cu is 0.2wt%; Zr is 0.1wt% ; Ga is 0.6wt%; Fe surplus; carry out quick-setting throwing strip, obtain the NdFeB quick-setting throwing sheet that average thickness is 0.2-0.4mm, fine microstructure, columnar crystal evenly arranged;

[0023] (b) The NdFeB quick-setting sheet obtained in the above steps is subjected to hydrogen breaking treatment, the hydrogen absorbing pressure is 0.2Mpa, the hydrogen absorbing time is 4 hours, and the dehydrogenation temperature is 520°C to obtain a coarse powder after hydrogen breaking;

[0024] (c) Add additives to the hydrogen-broken coarse powder obtained in the above steps. The additives are a mixture of antioxidants and lubricants, with a mass fraction of 0.6‰. Stir in a three-dimensional motion mixer for 1 hour and then perform jet milling powder, the oxygen content in the grinding ...

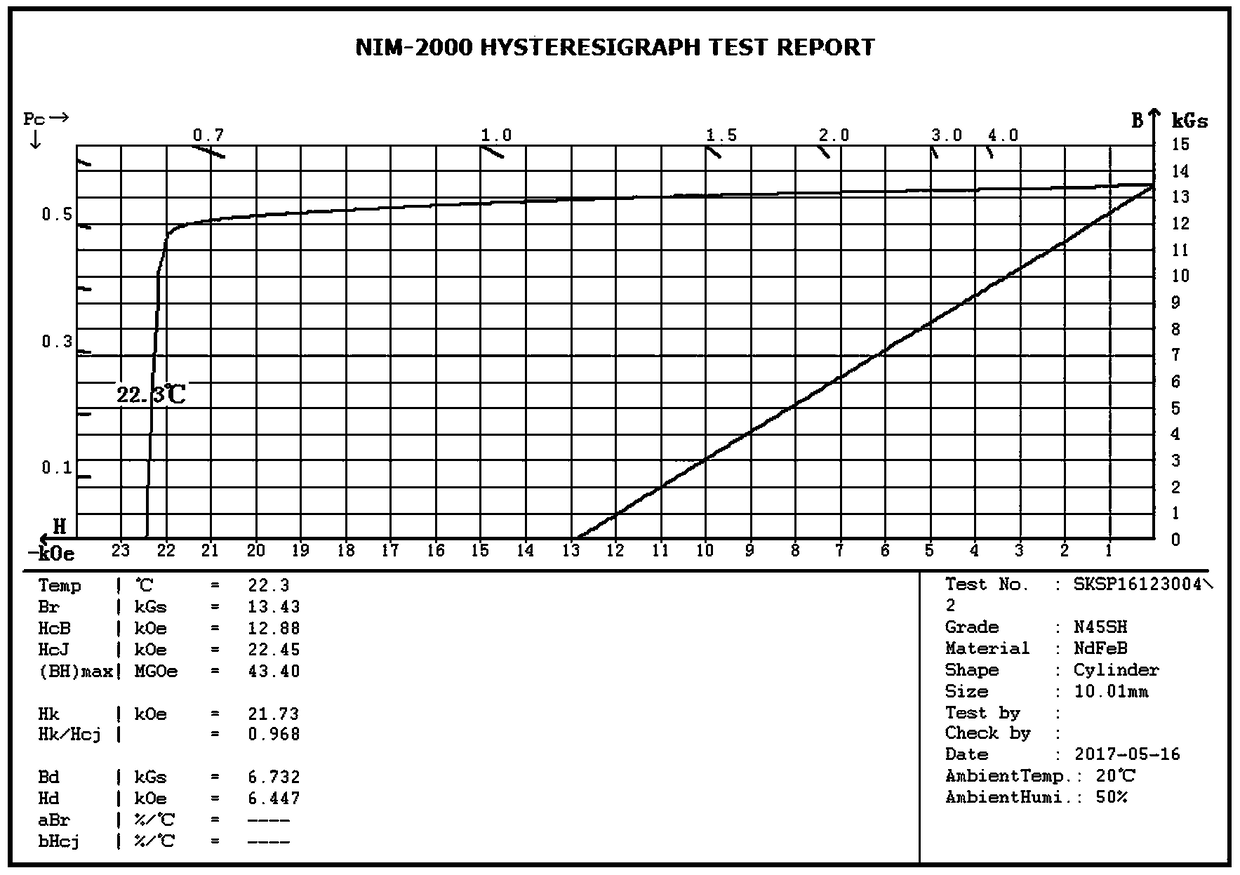

Embodiment 2

[0030] (a) The sintered NdFeB permanent magnet raw materials are based on weight percentage, Pr25Nd75 is 31.1wt%; B is 0.85wt%; Co is 1.2wt%; Al is 0.45wt%; Cu is 0.25wt%; Zr is 0.15wt% ; Ga is 0.65wt%; Fe surplus; carry out quick-setting throwing strip, obtain the NdFeB quick-setting throwing sheet that average thickness is 0.2-0.4mm, fine microstructure, columnar crystal evenly arranged;

[0031] (b) The NdFeB quick-setting sheet obtained in the above steps is subjected to hydrogen breaking treatment, the hydrogen absorbing pressure is 0.2Mpa, the hydrogen absorbing time is 4 hours, and the dehydrogenation temperature is 520°C to obtain a coarse powder after hydrogen breaking;

[0032] (c) Add additives to the hydrogen-broken coarse powder obtained in the above steps. The additives are a mixture of antioxidants and lubricants, with a mass fraction of 0.6‰. Stir in a three-dimensional motion mixer for 1 hour and then perform jet milling powder, the oxygen content in the grind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com