Preparation method of negative electrode material of lithium-ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of poor cycle stability and rate performance, low reversible capacity of silicon negative electrode materials, structural damage, etc., and achieve good cycle. The effect of stability, low cost and short holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

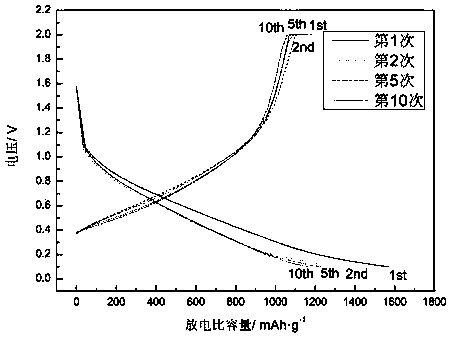

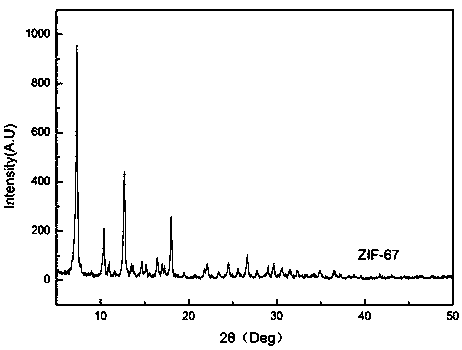

[0020] The preparation method of the nanometer Co / N / C / Si composite lithium-ion battery negative electrode material described in this embodiment specifically includes the following steps:

[0021] (1) Add cobalt nitrate hexahydrate and nano-silicon powder into 250ml of methanol solution to prepare a mixed solution, then stir magnetically and disperse ultrasonically for 30 minutes to obtain dispersion A; add 2-methylimidazole into 250ml of methanol solution, and then use magnetic Stir and disperse with an ultrasonic generator for 30 minutes to obtain dispersion B.

[0022] (2) Quickly mix the dispersion A and dispersion B in step (1), age at room temperature for 24 hours, then vacuum filter, wash repeatedly with methanol for 3 times, and dry at 60°C for 12 hours to obtain a powder A composite material of matter; wherein, the molar ratio of silicon, cobalt nitrate hexahydrate, and 2-methylimidazole is 2:1:4.

[0023] (3) Take out the dried powder in step (2), heat it up to 700°C...

Embodiment 2

[0031] The preparation method of the nanometer Co / N / C / Si composite lithium-ion battery negative electrode material described in this embodiment specifically includes the following steps:

[0032] (1) Add cobalt nitrate hexahydrate and nano-silicon powder into 250ml of methanol solution to prepare a mixed solution, then stir magnetically and disperse ultrasonically for 30 minutes to obtain dispersion A; add 2-methylimidazole into 250ml of methanol solution, and then use magnetic Stir and disperse with an ultrasonic generator for 30 minutes to obtain dispersion B.

[0033] (2) Quickly mix the dispersion A and dispersion B in step (1), age at room temperature for 24 hours, then vacuum filter, wash repeatedly with methanol for 3 times, and dry at 60°C for 12 hours to obtain a powder Composite material of substance; wherein the molar ratio of silicon, cobalt nitrate hexahydrate, and 2-methylimidazole is 2:1:4.

[0034] (3) Take out the dried powder in step (2), heat it up to 700°C...

Embodiment 3

[0038] The preparation method of the nanometer Co / N / C / Si composite lithium-ion battery negative electrode material described in this embodiment specifically includes the following steps:

[0039] (1) Add cobalt nitrate hexahydrate and nano-silicon powder into 250ml of methanol solution to prepare a mixed solution, then stir magnetically and disperse ultrasonically for 30 minutes to obtain dispersion A; add 2-methylimidazole into 250ml of methanol solution, and then use magnetic Stir and disperse with an ultrasonic generator for 30 minutes to obtain dispersion B.

[0040] (2) Quickly mix the dispersion A and dispersion B in step (1), age at room temperature for 24 hours, then vacuum filter, wash repeatedly with methanol for 3 times, and dry at 60°C for 12 hours to obtain a powder Composite material of substance; wherein the molar ratio of silicon, cobalt nitrate hexahydrate, and 2-methylimidazole is 1:1:4.

[0041] (3) Take out the dried powder in step (2), heat it up to 600°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com