Surface functionalization of silicon nanomaterials based on vinylsulfone

A technology of surface functionalization and nanomaterials, which is applied in the field of inorganic-organic composite preparation, can solve the problem of the oxide layer hindering the reaction, and achieve the effects of wide substrate applicability, strong selectivity, and increased reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Functionalization of colloidal silicon nanomaterials with polyethylene glycol 2000-vinyl sulfone (PEG 2000-VS) and its anti-protein adsorption function test

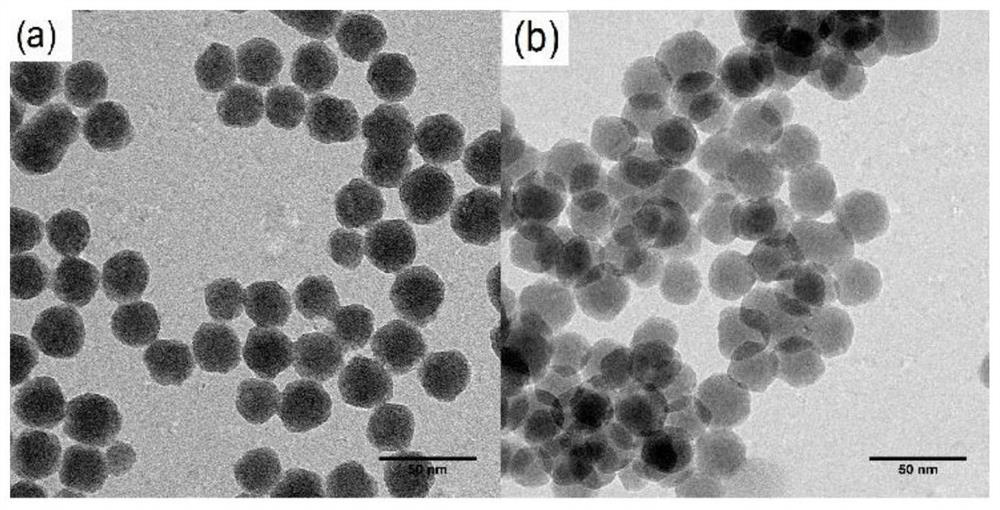

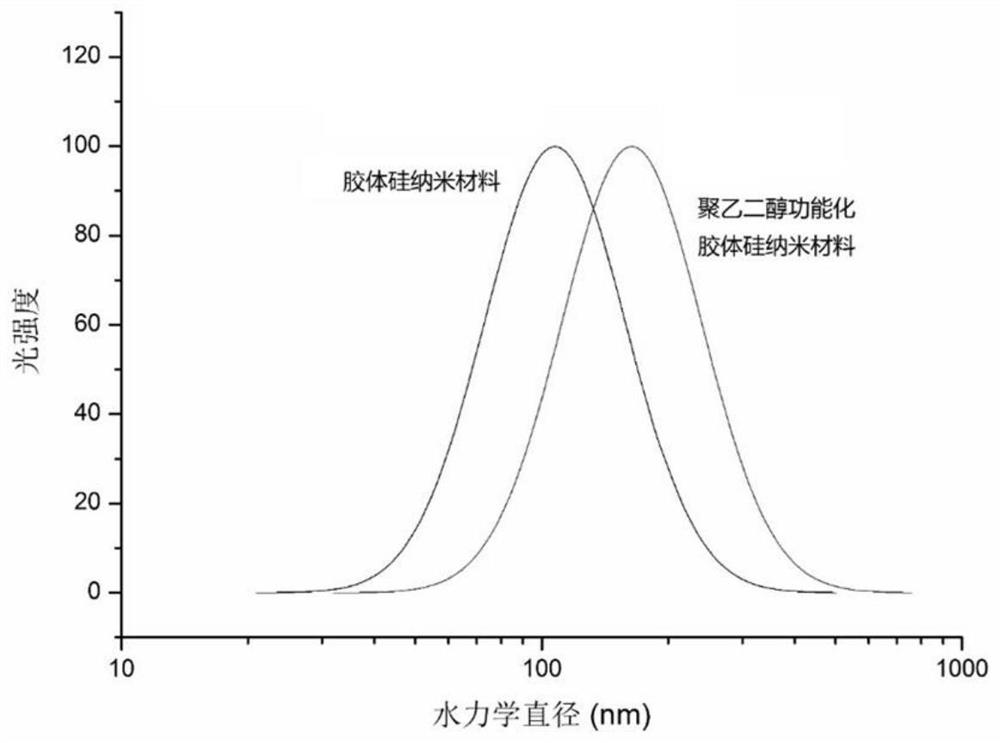

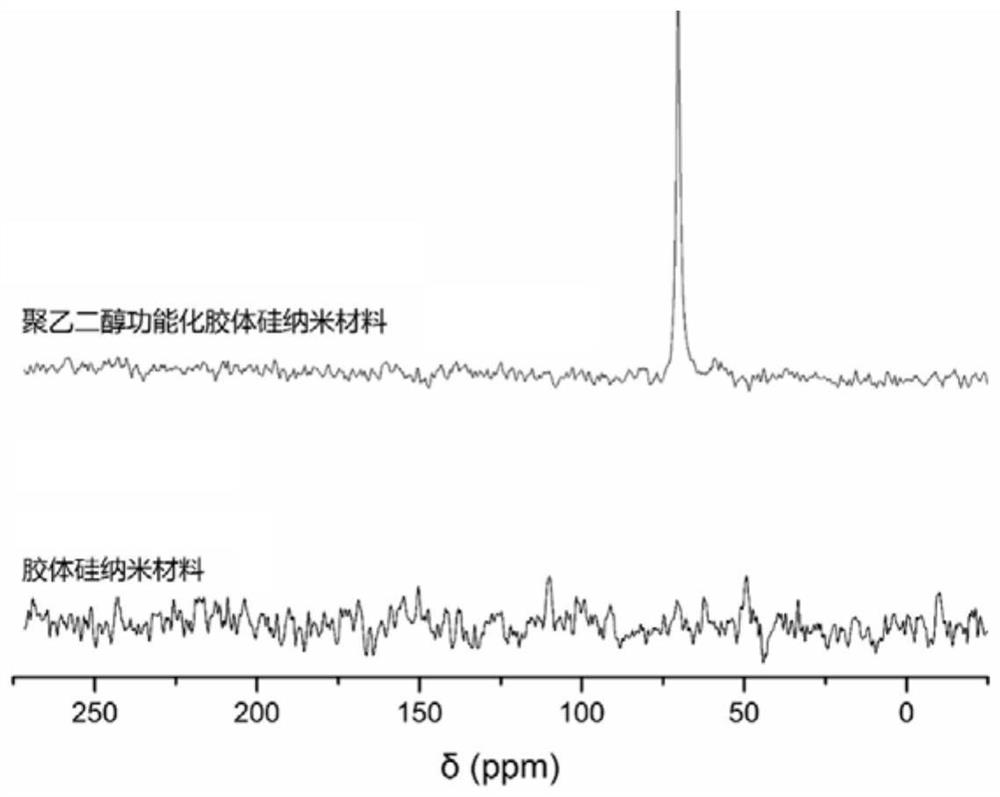

[0038] The colloidal silica nanomaterials (Colloidal silica, AS 40 TM , Sigma) dispersed in ethanol, acid treatment to increase the density of silanol on the surface of the material. The treated colloidal silica nanomaterials were centrifuged and washed three times with acetonitrile and stored for future use. Take 400 mg of the treated colloidal silicon nanomaterials and disperse them in 20 mL of acetonitrile. Add 500 mg of PEG 2000-VS into the colloidal silicon nanomaterial solution and fully dissolve it, add 65 mg of triphenylphosphine as a catalyst, and react under reflux for 12 hours. The PEG 2000-VS functionalized colloidal silica nanomaterials were obtained after centrifugation and washed three times with acetonitrile. Colloidal silica nanomaterials before and after functionalization were chara...

Embodiment 2

[0040] Example 2: Functionalization of Fumed Silica Material with Polyethylene Glycol 2000-Vinyl Sulfone (PEG 2000-VS)

[0041] 100 mg of fumed silica material (Sigma) was ultrasonically dispersed in 20 mL of acetonitrile. Add 1.0 g of PEG 2000-VS to the fumed silica material solution and fully dissolve it, add 262 mg of triphenylphosphine as a catalyst, and react under reflux for 12 hours. The PEG 2000-VS functionalized fumed silica material was obtained after centrifugation and three washes with acetonitrile. The dynamic light scattering method (DLS) was used to characterize the hydraulic diameter of the gas-phase silica material before and after functionalization, as shown in the attached Figure 6 shown. The particle size of fumed silica material functionalized with PEG2000-VS was about 50nm larger than that of unfunctionalized fumed silica material, indicating that the functionalization of PEG2000-VS was successful. The fumed silica material before and after functional...

Embodiment 3

[0042] Example 3: Functionalization of mesoporous silicon materials with polyethylene glycol 2000-vinylsulfone (PEG 2000-VS)

[0043] 50 mg of mesoporous silica material (MCM 41, Sigma) was ultrasonically dispersed in 10 mL of acetonitrile. Add 100 mg of PEG 2000-VS into the MCM 41 solution and fully dissolve it, add 37 mg of triphenylphosphine as a catalyst, and react under reflux for 12 hours. PEG 2000-VS functionalized MCM 41 was obtained after centrifugation and three washes with acetonitrile. MCM41 before and after functionalization was characterized using thermogravimetric analysis, as shown in the attached Figure 8 shown. The mass loss of PEG 2000-VS functionalized MCM 41 at 100 °C was due to the evaporation of solvent water adsorbed by nanomaterials; the mass loss at 350 °C was due to the formation of Si-O-C bond breakage, several Layer exfoliation, this phenomenon indicates that PEG 2000-VS functionalization was successful. Through thermogravimetric analysis, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com