Micro hotplate of silica-based structure and preparation method thereof

A micro-hot plate, silicon-based technology, applied in micro-structure technology, micro-structure devices, manufacturing micro-structure devices, etc. Expansion and shrinkage problems, to achieve the effect of low cost, increased thickness, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

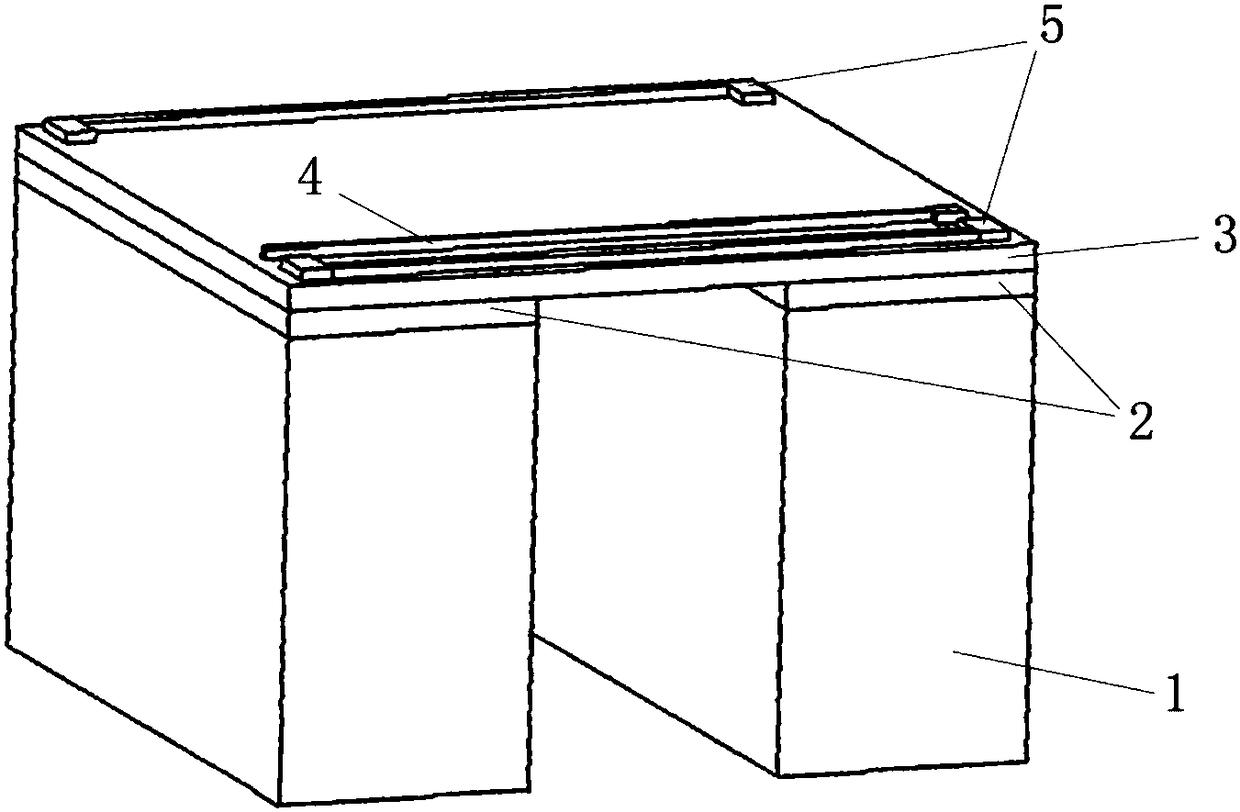

[0044] A silicon-based microhotplate, such as figure 1 shown. The substrate selects single crystal silicon with crystal orientation, such as Figure 5 As shown; firstly, porous silicon 2 is formed on a single crystal silicon substrate using an anodic oxidation method, such as Image 6 shown; then part of the porous silicon 2 is oxidized to form silicon dioxide 3, which is attached to the surface of the porous silicon 2, such as Figure 7 Shown; Spin glue on the surface of silicon dioxide 3, make positive photoresist 6 evenly distributed on silicon dioxide 3, as Figure 8 As shown, in order to increase the adhesiveness between the positive photoresist 6 and the silicon dioxide 3, it is dried immediately after spinning the resist.

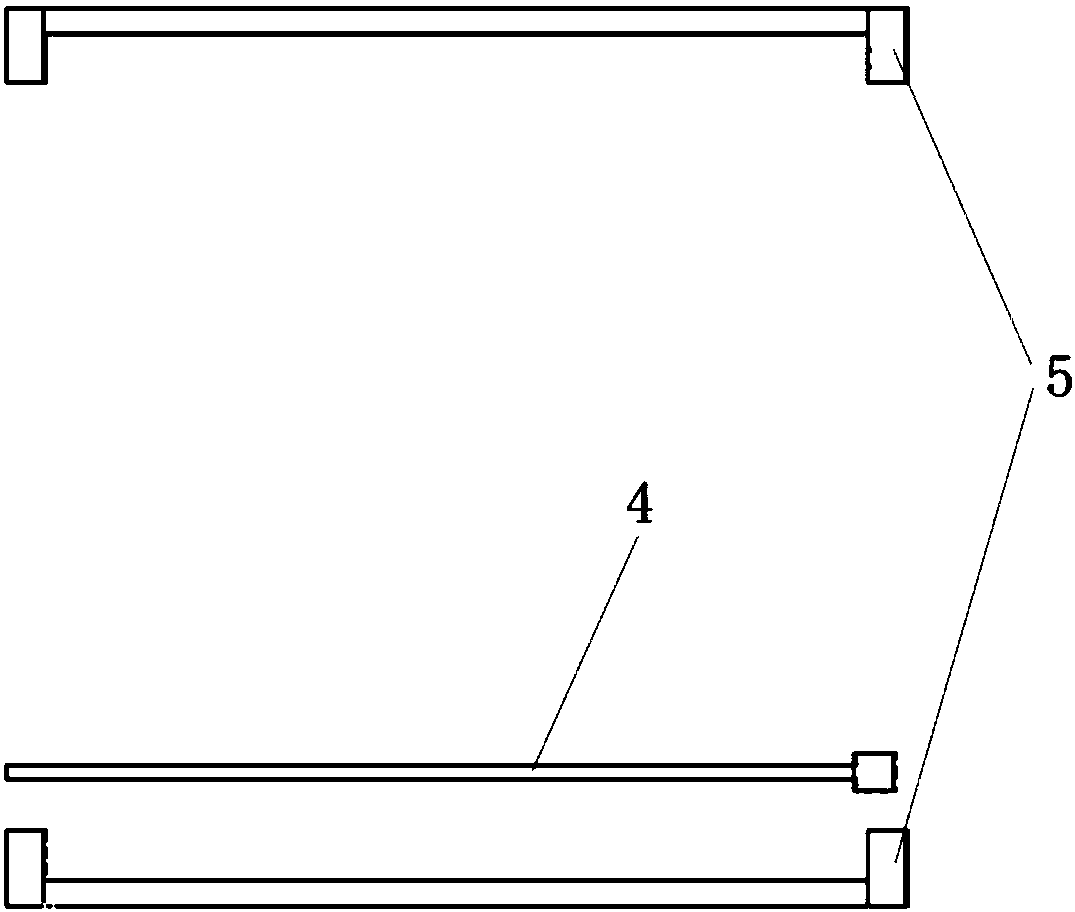

[0045] according to figure 2 According to the shape of the electrode, the corresponding mask plate 7 is engraved, so that only the position of the sputtering electrode is exposed on the silicon wafer, and the other parts are protected with phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com