Pressure sensor and preparation method thereof

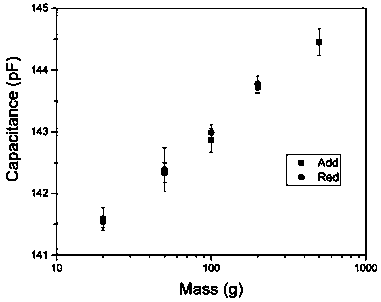

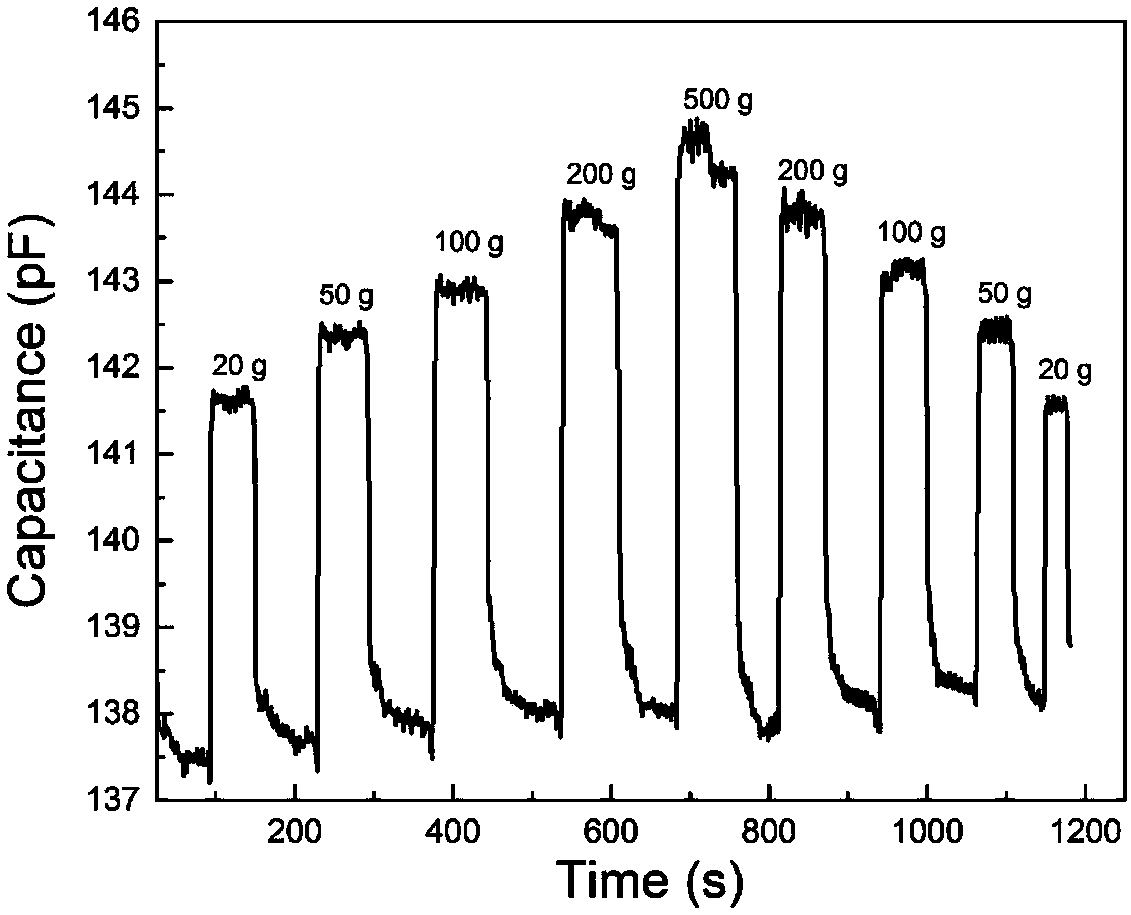

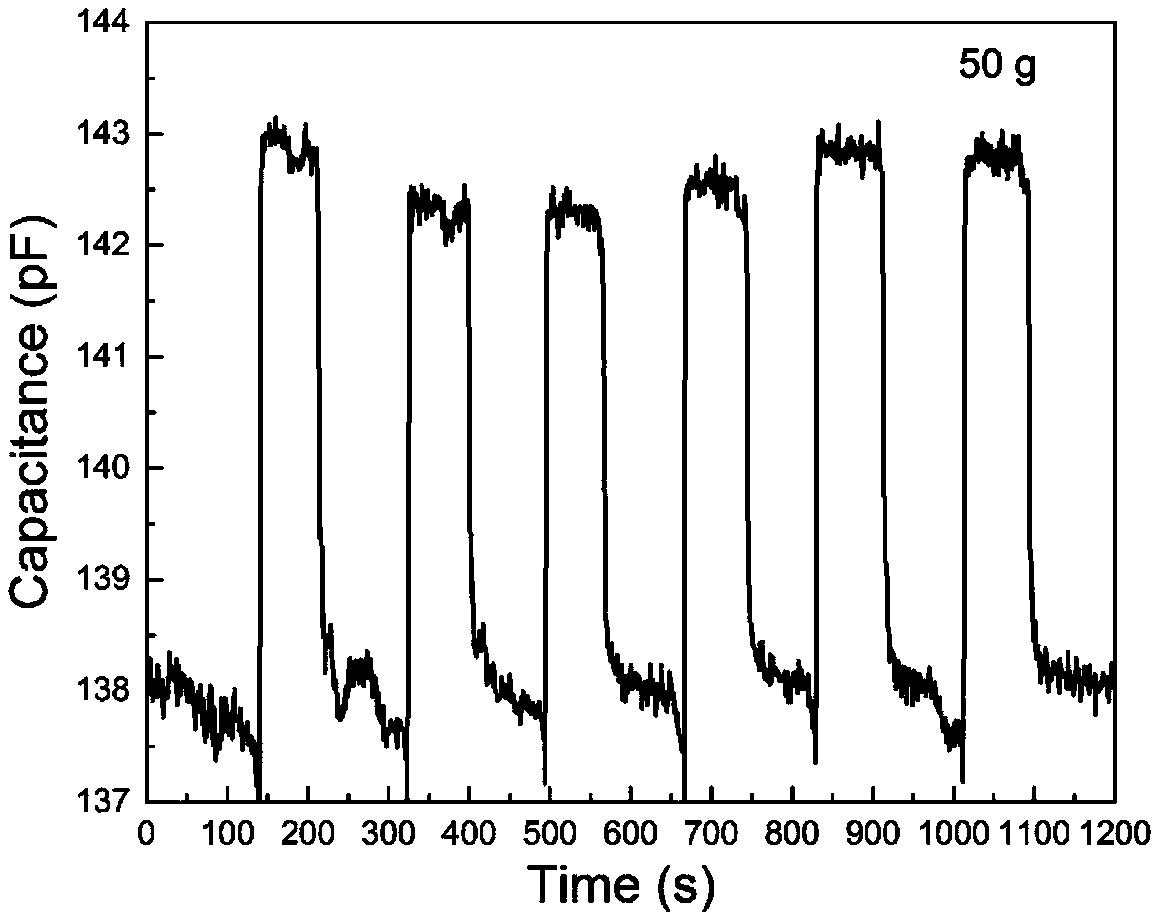

A pressure sensor and coating technology, applied in the direction of instruments, measuring forces, measuring devices, etc., can solve the problems of increased electrode sensitivity, many parameters, expensive equipment, etc., and achieve the effects of good linear response, high sensitivity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of the pressure sensor:

[0033] 1) Preparation of the flexible electrode array: strip-shaped silver electrode stripes are inkjet printed on the flexible substrate, and the width and spacing of the electrode stripes can be adjusted as required.

[0034] 2) Preparation of PDMS pressure-sensitive adhesive: After mixing and stirring the PDMS matrix and curing agent at a ratio of 10:1 for 30 minutes, let it stand in a vacuum environment for 20 minutes to remove air bubbles, and finally obtain a viscous PDMS pressure-sensitive adhesive.

[0035] 3) Apply the PDMS pressure-sensitive adhesive to the flexible electrode array, and then select two electrodes of the same size coated with PDMS pressure-sensitive adhesive to attach to form a sandwich structure. The two electrode arrays are perpendicular to each other. After curing at 70°C for 2 hours A flexible pressure sensor is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com