Modification method of macroporous resin for adsorbing low-concentration sulfur dioxide in air

A sulfur dioxide, low-concentration technology, used in chemical instruments and methods, separation methods, gas treatment and other directions, can solve problems such as unsatisfactory adsorption mechanism effects, achieve excellent adsorption effects, easy reaction conditions, and avoid carcinogenic hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

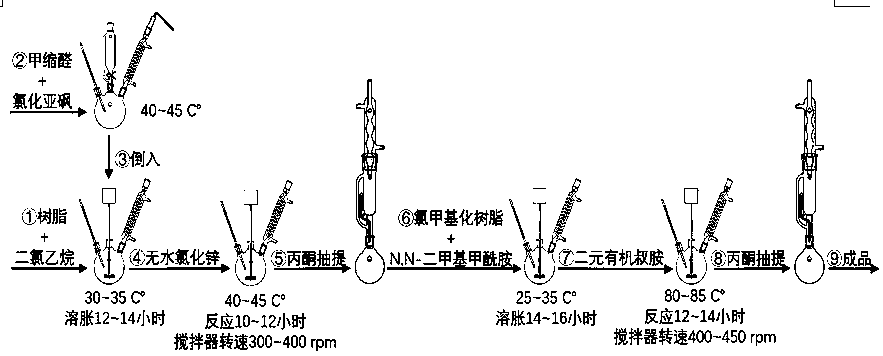

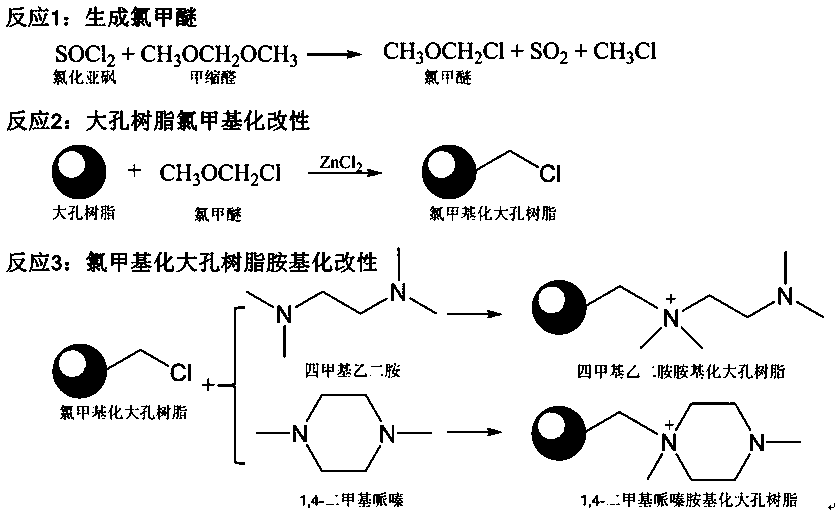

Method used

Image

Examples

Embodiment 1

[0029] Take 20 g of purchased polystyrene-type D101 macroporous adsorption resin, with a particle size of 0.3-1.25 mm and a specific surface area of 550-600 m 2 / g, with an average pore size of 9-10 nm, fully cleaned with ultrapure water. Take 15 g of the above-mentioned pretreated resin and put it into a three-necked flask equipped with a thermometer, a stirrer, and a reflux condenser, add 100 g of dichloroethane solution, and swell at 30 ° C for 12 hours. Add 50 g of methylal solution to another three-necked flask equipped with a thermometer, a dropping funnel, and a reflux condenser, and keep the temperature at 40 ° C. Slowly add 50 g of thionyl chloride solution dropwise at a rate of 3 mL / min, after the dropwise addition was completed, all the resulting reaction mixture solution was poured into a three-necked flask filled with resin. Then add 5 g of anhydrous zinc chloride powder as a catalyst in a three-necked flask filled with resin, and fully react for 10 hours at 40...

Embodiment 2

[0032] Take 20 g of purchased polystyrene-type D101 macroporous adsorption resin, with a particle size of 0.3-1.25 mm and a specific surface area of 550-600 m 2 / g, with an average pore size of 9-10 nm, fully cleaned with ultrapure water. Take 15 g of the above-mentioned pretreated resin and put it into a three-necked flask equipped with a thermometer, a stirrer, and a reflux condenser, add 100 g of dichloroethane solution, and swell at 30 ° C for 12 hours. Add 50 g of methylal solution to another three-necked flask equipped with a thermometer, a dropping funnel, and a reflux condenser, and keep the temperature at 40 ° C. Slowly add 50 g of thionyl chloride solution dropwise at a rate of 3 mL / min, after the dropwise addition was completed, all the resulting reaction mixture solution was poured into a three-necked flask filled with resin. Then add 5 g of anhydrous zinc chloride powder as a catalyst in a three-necked flask filled with resin, and fully react for 10 hours at 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com