Method for Improving the Biosynthetic Yield of Ansamitocin p-3

A technology of biosynthesis and ansamitocin, applied in the field of bioengineering, can solve the problems of low biosynthesis yield and limited commercial application, and achieve the effect of increasing yield and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

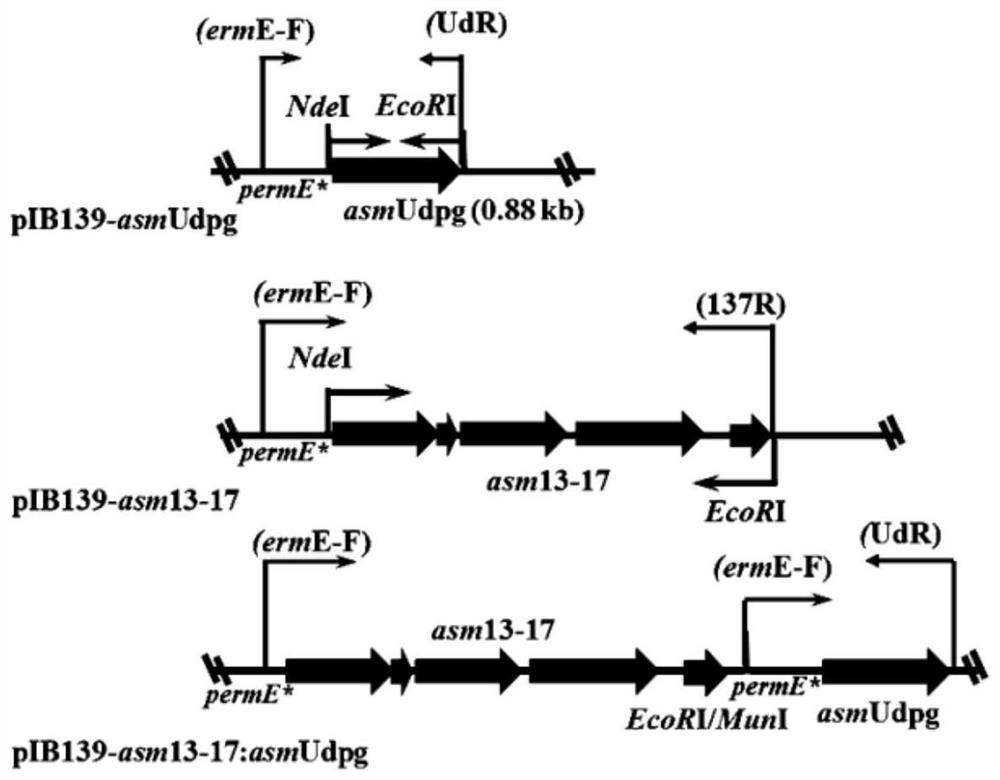

[0033] Such as figure 1 As shown, this embodiment realizes the construction of three expression plasmids and corresponding bacterial strains through the following specific steps:

[0034] ① Construction of the expression plasmid pIB139-asm13-17, specifically: using the genomic DNA of Actinomyces aurantiaciensis ATCC31565 as a template, using 137F / 137R primers to obtain a 4,451bp end containing NdeI / EcoRI enzymes through PCR amplification The asm13-17 fragment of the cutting site, the resulting gene fragment, is connected to pMD @ On the 19-T vector, asm13-17-19T was obtained; the correctness of the sequence was verified by sequencing, digested with NdeI / EcoRI, and connected with the corresponding digested pIB139 plasmid, and the plasmid for asm13-17 gene expression was obtained pIB139-asm13-17.

[0035]The 137F / 137R primers include: asm13-17-upstream primer (137F), as shown in Seq ID No.3, specifically: 5'-GGGAATTC CATATG GTGCCCGGCGACACCGAC-3'; asm13-17-downstream primer (...

Embodiment 2

[0051] The wild-type strain and the engineering bacteria constructed in Example 1 were shaken for fermentation and culture respectively, and the seed medium used for the culture contained (g / l): yeast extract 10, beef extract 10, anhydrous glucose 5, glycerin 10 and sodium chloride 3; fermentation medium (g / l): anhydrous glucose 5, glycerol 40, yeast extract 10, sucrose 2.5, calcium carbonate 2, dipotassium hydrogen phosphate 0.65, magnesium sulfate heptahydrate 0.5, sulfuric acid heptahydrate Ferrous iron 0.002, calcium carbonate 2, isobutanol 200μl / 60ml, aliquot 60ml / 250ml.

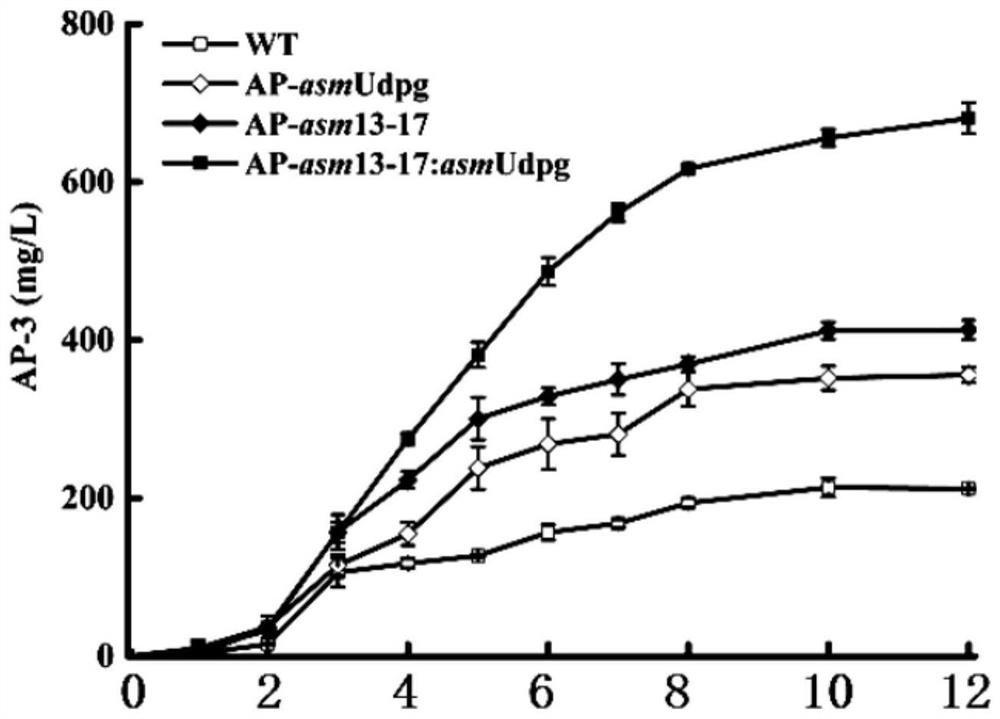

[0052] The fermentation culture of the above-mentioned bacterial strains was cultivated according to the method described in the literature (Lin JX et al., Bioresource Technology, 2011, 102 (2): 1863-1868). After primary and secondary seed cultivation respectively, the wild-type strain ATCC31565 and the constructed The seed solution of the obtained engineered bacteria is inserted into the fermentation m...

Embodiment 3

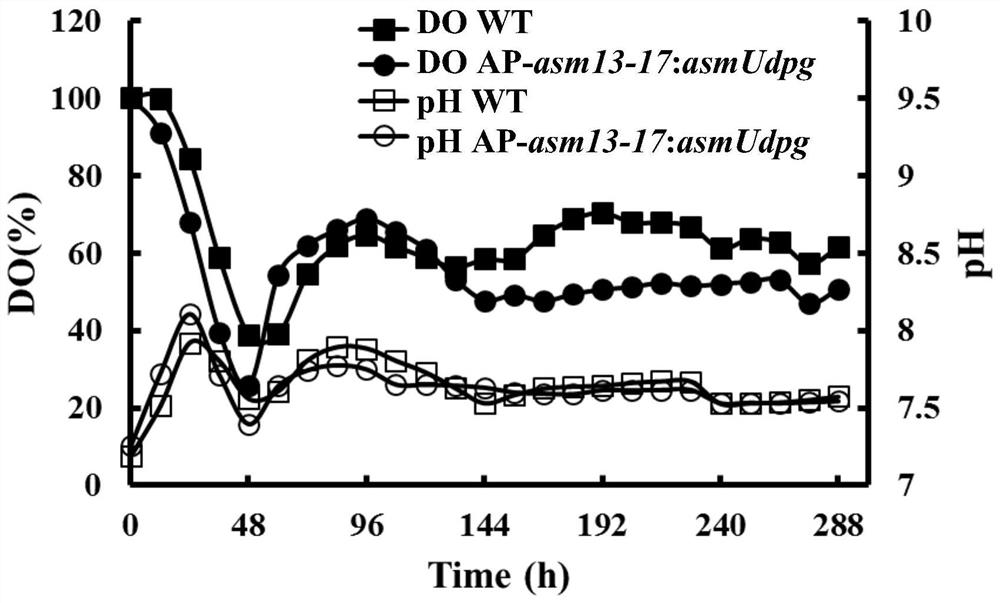

[0057] Fermentation of AP-3 in 3L-Fermenter

[0058] Seed culture: According to the cultivation of the seed culture solution in Example 2, through the primary and secondary seed cultivation, the secondary seed is cultivated for about 36 hours, and inoculated according to the ratio of 1ml seed solution / 60ml medium.

[0059] Using a 3L fermenter (NBS BioFlo110), prepare 1.8L according to the fermentation medium formula in Example 2, 121°C, and sterilize for 30min, and introduce Actinomyces aurantiacens ATCC31565 and pIB139-asm13-17 in Example 1: AP-asm13-17 of the asmUdpg plasmid: asmUdpg engineering bacteria seeds were aseptically inoculated, and 6ml of isobutanol was added at the same time. The culture conditions were temperature 28°C, pH 7.5, rotation speed 400rpm, ventilation volume 1VVM, K L a=70h -1 Conditions for batch fermentation. The AP-3 output was 547 mg / L as measured by HPLC at the end of the fermentation. The dynamic process of dissolved oxygen, pH, cell mass an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com