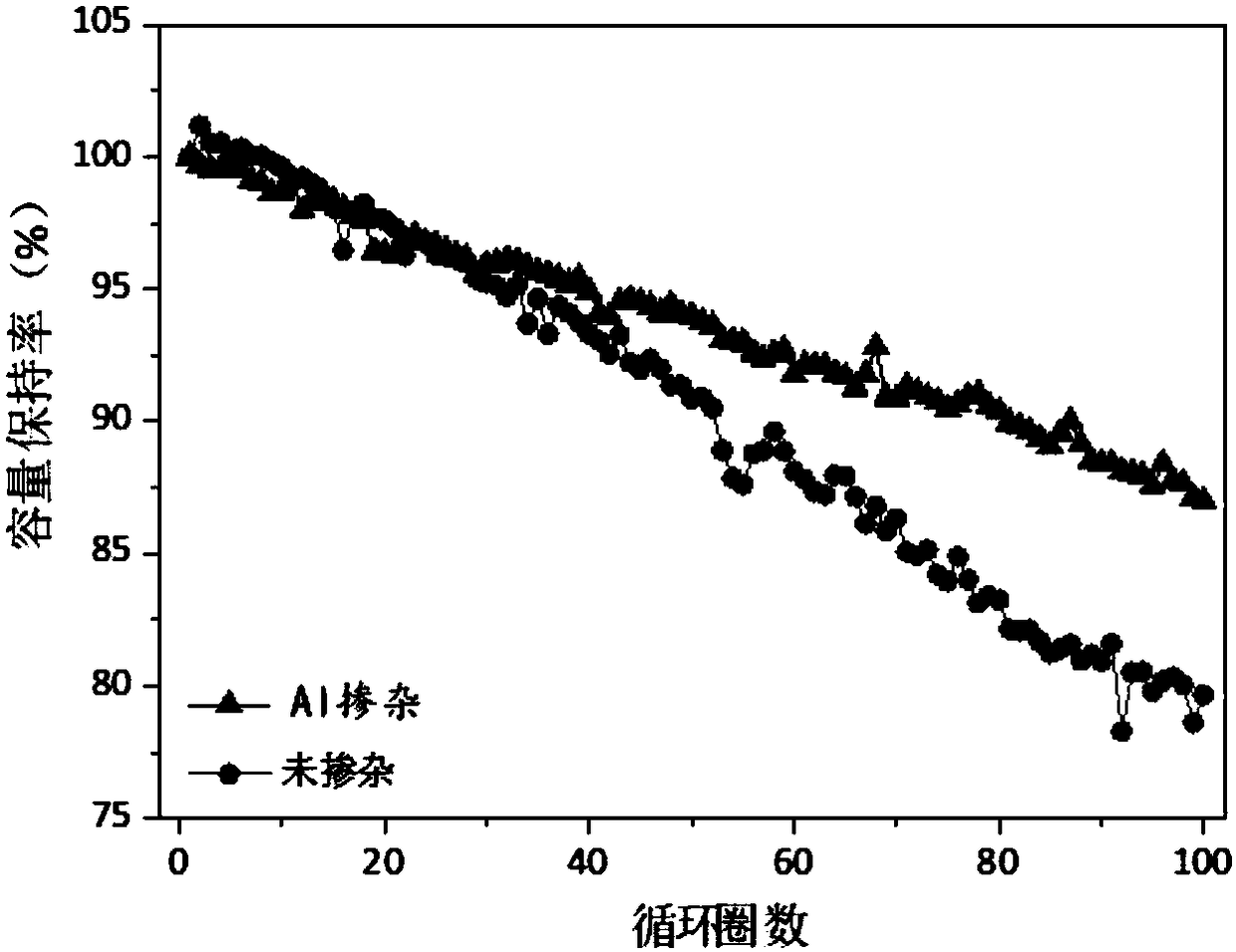

Doped nickel-cobalt-aluminum ternary lithium-ion battery positive electrode material as well as preparation method and application

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as reducing material cycle stability, increasing battery impedance, and reducing coating effects, so as to improve electrochemical performance and reduce Impedance, the effect of improving the coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of the doped nickel-cobalt-aluminum ternary lithium-ion battery positive electrode material of the embodiment of the present invention comprises the following steps:

[0050] Step (1), the first sintering: the ternary cathode material precursor Ni 1-x-y co x Al y (OH) 2+y Sintering; sintering time 6-20 hours, sintering temperature 200-1000 ℃;

[0051] Step (2), the second sintering: add the sintered product of the step (1) to the lithium source and the dopant material to mix and grind according to a certain ratio, after the grinding is uniform, sinter in air or oxygen atmosphere, after the sintering is completed, Cool down to room temperature at a cooling rate of 0.01-2.5°C / min;

[0052] Step (3), the third sintering: sintering the sintered product of the step (2), the sintering time is 1-12 hours, the sintering temperature is 500-1000°C, and the positive electrode of the doped nickel-cobalt-aluminum ternary lithium-ion battery is obtained Ma...

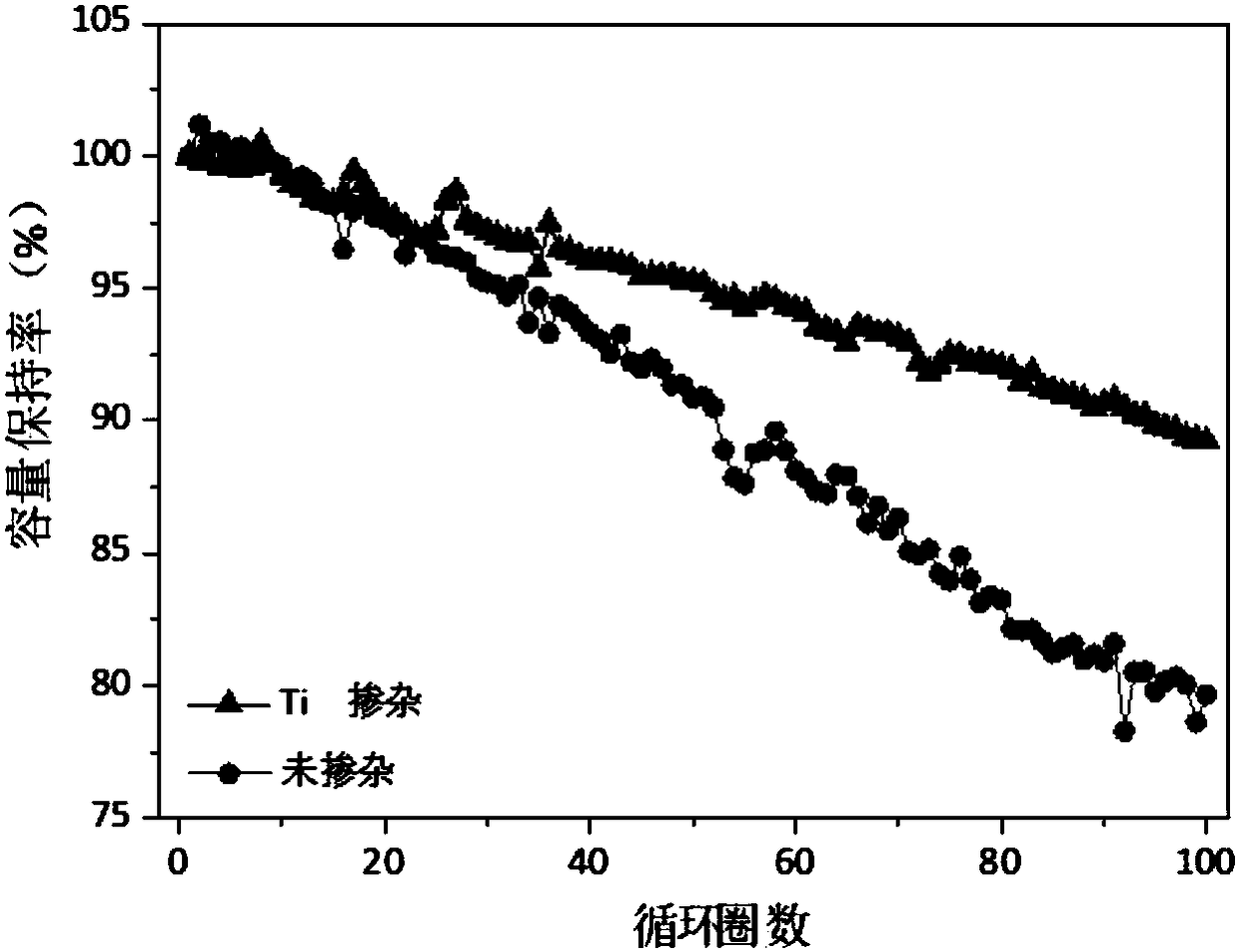

Embodiment 1

[0059] What embodiment 1 provides is Ti-doped nickel-cobalt-aluminum ternary lithium-ion battery cathode material (Li 1.035 Ni 0.815 co 0.15 Al 0.035 ) 0.9993 Ti 0.0007 o 2 , M is Ti, x=0.15, y=0.035, a=1.035, b=0.0007. The Ti-doped nickel-cobalt-aluminum ternary lithium-ion battery cathode material (Li 1.035 Ni 0.815 co 0.15 Al 0.035 ) 0.9993 Ti 0.0007 o 2 The preparation method comprises the following steps:

[0060] Step (1), the first sintering: the ternary cathode material precursor Ni 1-x-y co x Al y (OH) 2+y Sintering, heating up to 500°C for 10 hours;

[0061] Step (2), the second sintering: After drying lithium hydroxide monohydrate until the crystal water is completely lost, sinter the resultant and the doping material TiO with the step (1) 2 Mixing and grinding, the amount of lithium hydroxide monohydrate is Li in lithium hydroxide monohydrate and (Ni+Co+Al) in the precursor of the ternary positive electrode material The molar ratio is 1.035: 1, Ti...

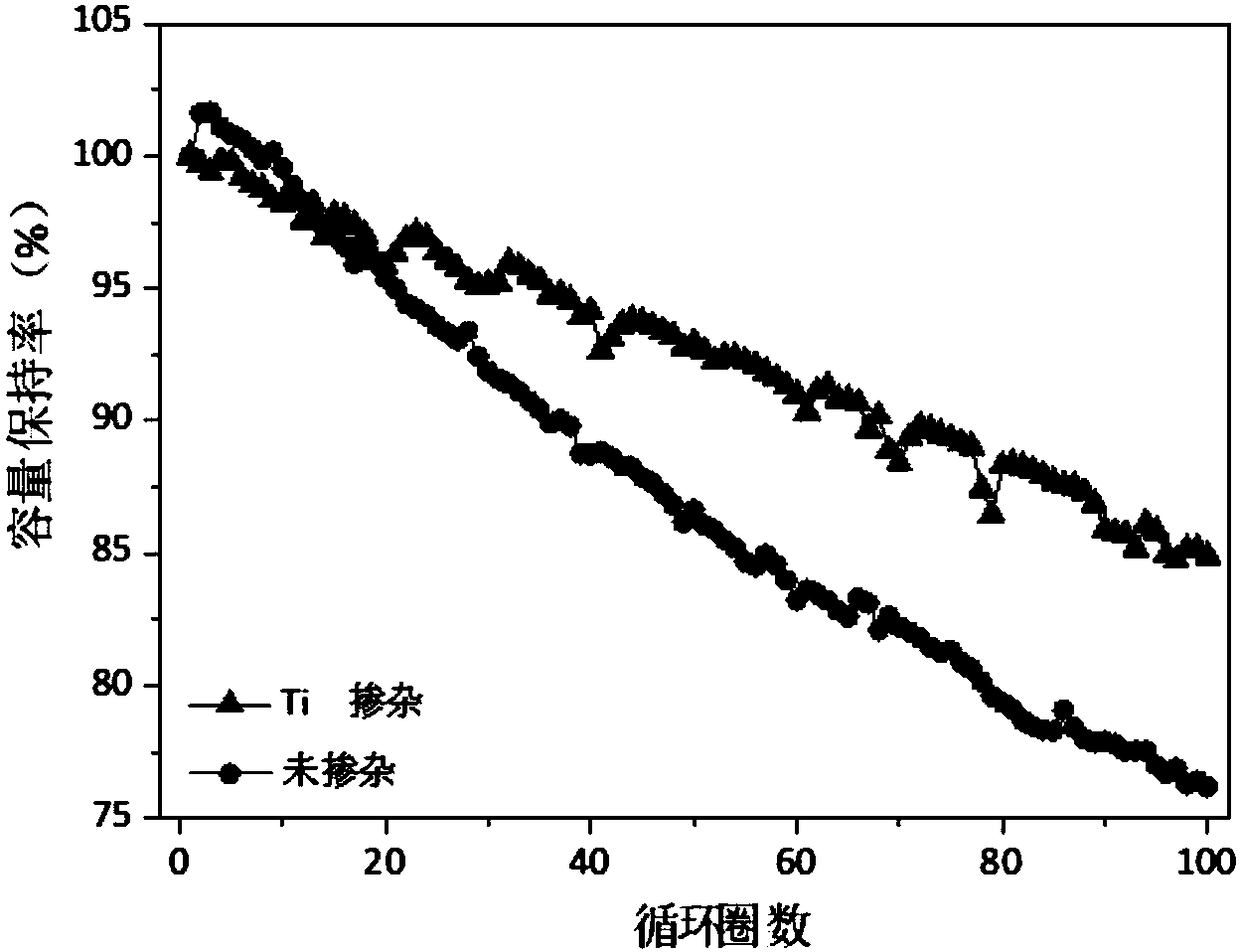

Embodiment 2

[0066] What embodiment 2 provides is Ti-doped nickel-cobalt-aluminum ternary lithium-ion battery cathode material (Li 1.035 Ni 0.815 co 0.15 Al 0.035 ) 0.9981 Ti 0.0019 o 2 , M is Ti, x=0.15, y=0.035, a=1.035, b=0.0019. The Ti-doped nickel-cobalt-aluminum ternary lithium-ion battery cathode material (Li 1.035 Ni 0.815 co 0.15 Al 0.035 ) 0.9981 Ti 0.0019 o 2 The preparation method comprises the following steps:

[0067] Step (1), the first sintering: the ternary cathode material precursor Ni 1-x-y co x Al y (OH) 2+y Sintering, heating up to 600°C for 6.5 hours;

[0068] Step (2), the second sintering: After drying lithium hydroxide monohydrate until the crystal water is completely lost, sinter the resultant and the doping material TiO with the step (1) 2 Mixing and grinding, the amount of lithium hydroxide monohydrate is Li in lithium hydroxide monohydrate and (Ni+Co+Al) in the precursor of the ternary positive electrode material The molar ratio is 1.035: 1, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com