Framework material for lithium metal battery negative electrode and preparation method of framework material as well as lithium metal battery negative electrode

A technology for lithium metal batteries and skeleton materials, applied in the direction of electrode carriers/collectors, secondary batteries, circuits, etc., can solve the problems of lithium metal and electrolyte consumption, low electrode potential, complex preparation methods, etc., and achieve improved cycle stability The effect of stability, stable charge and discharge voltage, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

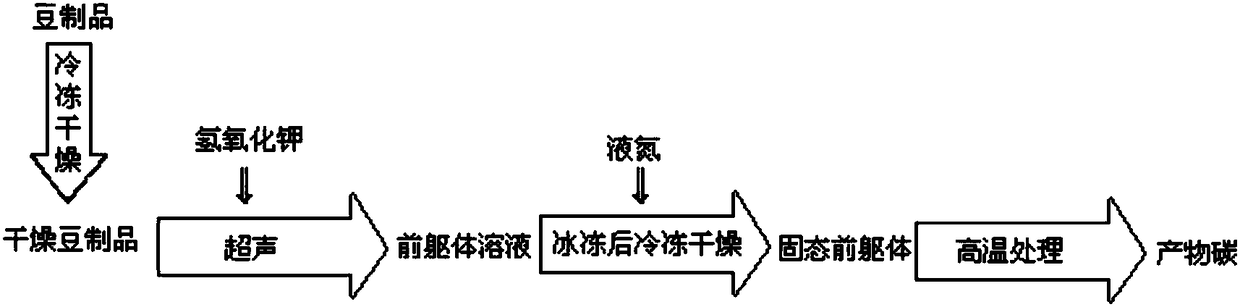

[0033] The invention provides a method for preparing a lithium metal battery negative electrode framework material, comprising the following steps:

[0034] a), mixing the soybean product and the KOH solution, and ultrasonically obtaining the precursor solution;

[0035] b), freezing the precursor solution with liquid nitrogen and then vacuum freeze-drying to obtain a layered precursor;

[0036] c) activating and carbonizing the layered precursor at 700-800° C. to obtain a lithium metal battery negative electrode framework material.

[0037] The preparation method provided by the invention uses abundant and cheap soy product biomass as a raw material, and through one-step activation and carbonization, the method is simple and easy, and the raw materials are widely and easily available; The anode material of the metal battery can improve the cycle stability of the battery.

[0038] The present invention mixes soybean product and KOH solution, and ultrasonically obtains precur...

Embodiment 1

[0065] (1) Weigh a certain amount of fresh tofu, wash it three times with deionized water at room temperature, put it in a 500mL petri dish, put it in the freezing layer of the refrigerator (-18°C) and take it out after freezing for 24 hours; then put it in Dry in a vacuum freeze dryer to form loose dried tofu. The temperature of the freeze dryer is -70°C and the air pressure is 10Pa;

[0066] (2) Weigh 15g of dry tofu obtained in step (1) and put it into 150mL, the mass concentration is 10mg mL -1 In the KOH aqueous solution, the mass ratio of dry tofu to activator is 5:1; mix in an ultrasonic machine to obtain a homogeneous precursor solution; the ultrasonic working frequency is 53kHz, the ultrasonic time is 30min, and the ultrasonic temperature is 30°C;

[0067] (3) Package the precursor solution obtained in step (2) in a beaker with plastic wrap, put it in liquid nitrogen, take it out after 20 minutes, put it in a vacuum freeze dryer, and take out the loose and porous prec...

Embodiment 2

[0072] The difference from Example 1 is that the mass ratio of KOH to dried tofu is 3:5.

[0073] The present invention has carried out X-ray photoelectron energy spectrum analysis (XPS) to the lithium metal battery negative pole framework material prepared in Example 2, and the C content of lithium metal battery negative pole framework material is 95wt%, and N content is 0.82wt% and O content 4.18 wt%. The test results show that the heteroatom-doped chemical properties of the lithium metal battery anode framework material provide abundant lithium-friendly sites.

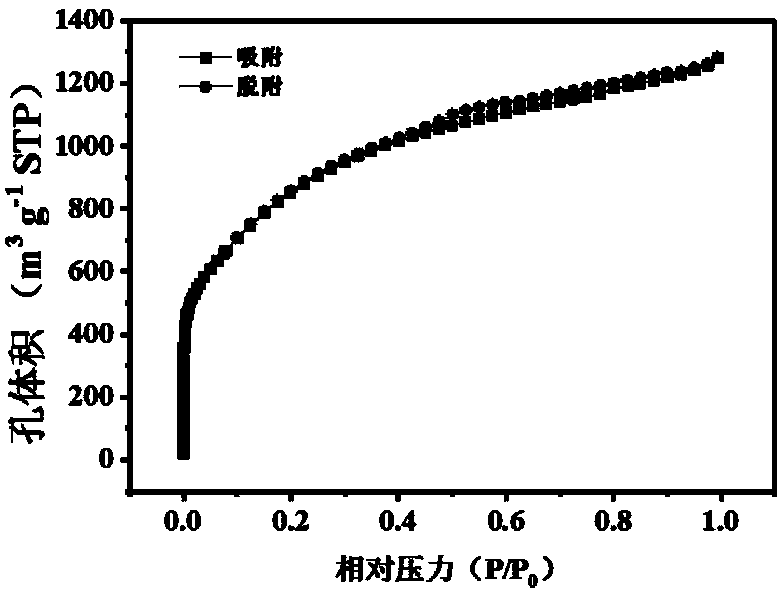

[0074] image 3 The nitrogen adsorption and desorption curve of the lithium metal battery negative electrode framework material prepared in Example 2 of the present invention; its specific surface area is as high as 3134m 2 g -1 .

[0075] Figure 4 The pore size distribution diagram of the lithium metal battery negative electrode framework material prepared in Example 2 of the present invention; the mesopores ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge current density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com