Side chain type homogeneous anion exchange membrane and preparation method thereof

A technology of anion exchange membrane and side chain, which is applied in the field of side chain type homogeneous anion exchange membrane and its preparation, can solve the problems of low conductivity and poor stability of anion exchange membrane, and achieve high ion conductivity, good stability, The effect of high response controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

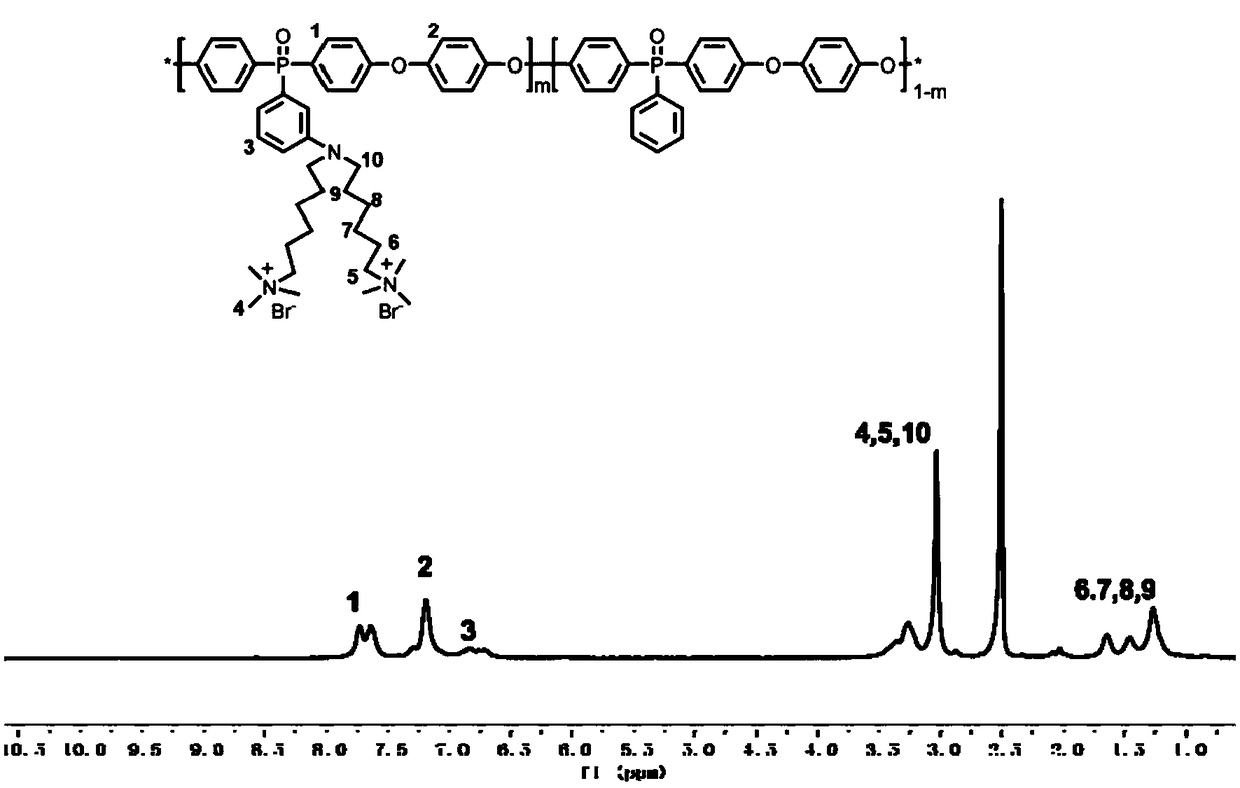

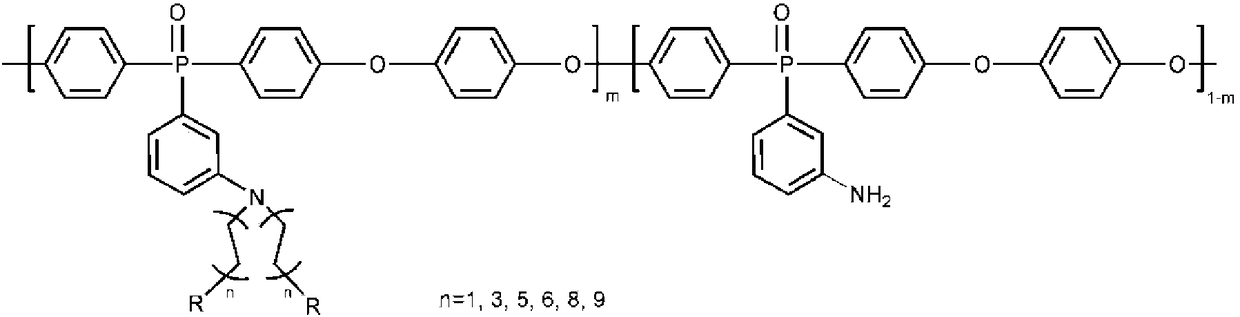

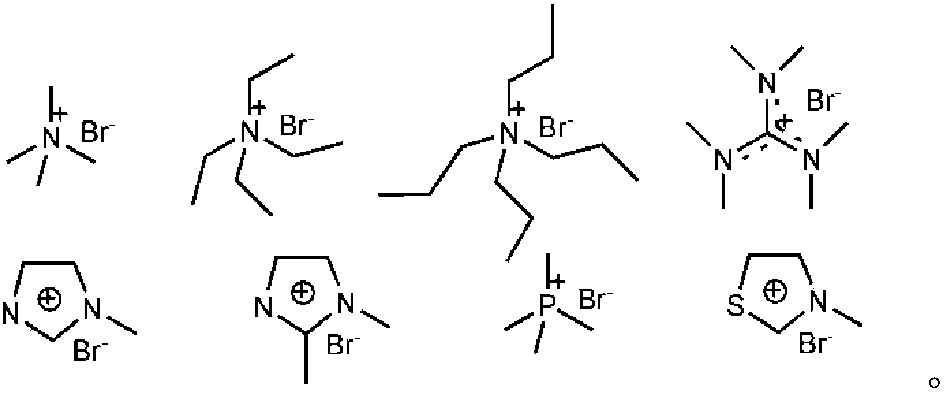

Method used

Image

Examples

Embodiment 1

[0045] 1, the preparation of the basic functionalization reagent that contains Bian bromine group: in the one-necked flask of 100mL, add 1,6-dibromohexane 0.244g (1mmol), add 20mL acetone as solvent, utilize magnetic stirring to react liquid Stir to ensure that the system is evenly mixed; 0.04926g (0.6mmol) of 1-methylimidazole is dissolved in 20mL of acetone, and the acetone solution of trimethylamine is slowly added dropwise to the single-necked flask using a constant pressure dropping funnel, and the After reacting for 10 hours, stop stirring, and filter the reaction solution with suction to obtain a white solid, and add acetone again to wash and remove unreacted raw materials. body;

[0046] 2. Preparation of side chain type polymers: Add 0.5g polyphenylene phosphine oxide polymer into a 100mL three-necked flask, add 20ml N-methylpyrrolidone as a solvent, after the reactants are completely dissolved, blow nitrogen, add 1390μL N, N-diisopropylethylamine was used as an acid...

Embodiment 2

[0050] 1. Preparation of the basic functionalization reagent containing Bian bromine group: adopt the same preparation process as in Example 2, the amount of the basic functionalization reagent added is 0.8mmol, and a monomer with similar structure is obtained.

[0051] 2. Preparation of side chain type polymer: adopt the same preparation process as in Example 2.

[0052] 3. Film formation: the same preparation process as in Example 2 was adopted.

[0053] After measurement, the water content of the homogeneous anion exchange membrane prepared in this embodiment is 31.6%, the ion exchange capacity is 1.57mmol / g dry film, and the OH - The conductivity is 3.8×10 -2 S / cm.

Embodiment 3

[0055] 1, the preparation of the basic functionalization reagent containing Bian bromine group: adopt the preparation process identical with embodiment 2, the basic functionalization reagent added changes triethylamine into.

[0056] 2. Preparation of side chain type polymer: the same preparation process as in Example 2 was adopted, and the mass of the basic functionalized monomer containing Bian bromine group was added to be 3.2 g.

[0057] 3. Film formation: the same preparation process as in Example 2 was adopted.

[0058] After measurement, the water content of the homogeneous anion exchange membrane prepared in this embodiment is 51.6%, the ion exchange capacity is 1.66mmol / g dry film, and the OH - The conductivity is 4.5×10 -2 S / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com