P-nitrophenol hydrogenated loaded yolk-eggshell nanostructure catalyst and preparation method

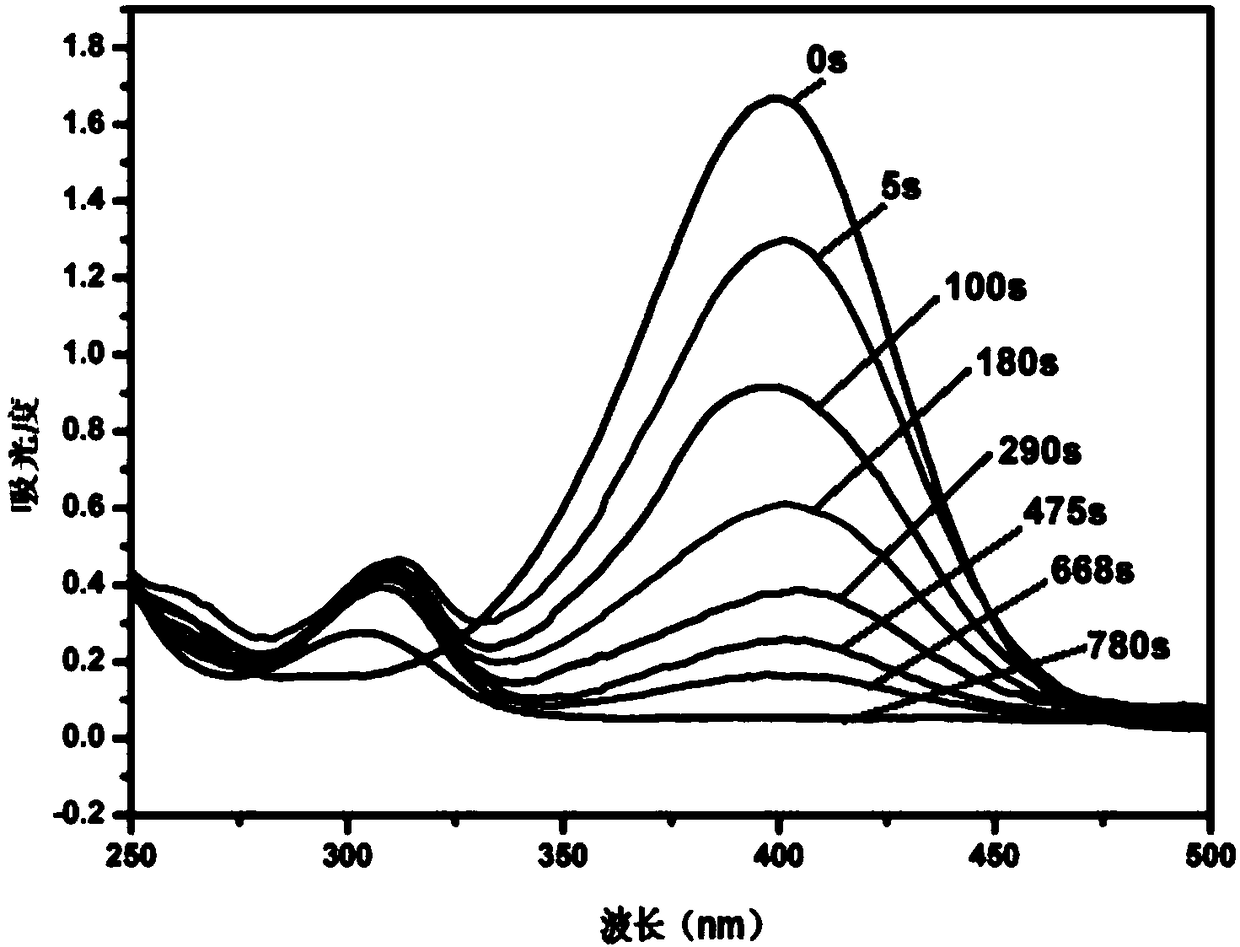

A technology of p-nitrophenol and nanostructure, which is applied in the field of loaded egg yolk-eggshell nanocatalyst and its preparation, can solve the problems of increasing the production cost of aminophenol, the limitation of aminophenol production, and the expensive price of palladium catalyst, etc., and achieve the synthesis Low cost, good catalytic activity, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The method for preparing the above-mentioned supported egg yolk-egg shell nanostructure catalyst for hydrogenation of p-nitrophenol includes the following steps:

[0044] S1. Grind the washed and dried biomass through a screen to make biomass powder; under the protection of inert gas, the biomass powder is carbonized in a tube furnace to obtain a carbonized powder, which is acid-washed to adjust the pH; dried and piped The carrier biomass charcoal is obtained by the second carbonization of the furnace;

[0045] S2. The biomass charcoal and the transition metal salt are added to the dispersant and dispersed to obtain a dispersion;

[0046] S3. Separate the dispersion, wash and dry the precipitate to obtain a precursor powder;

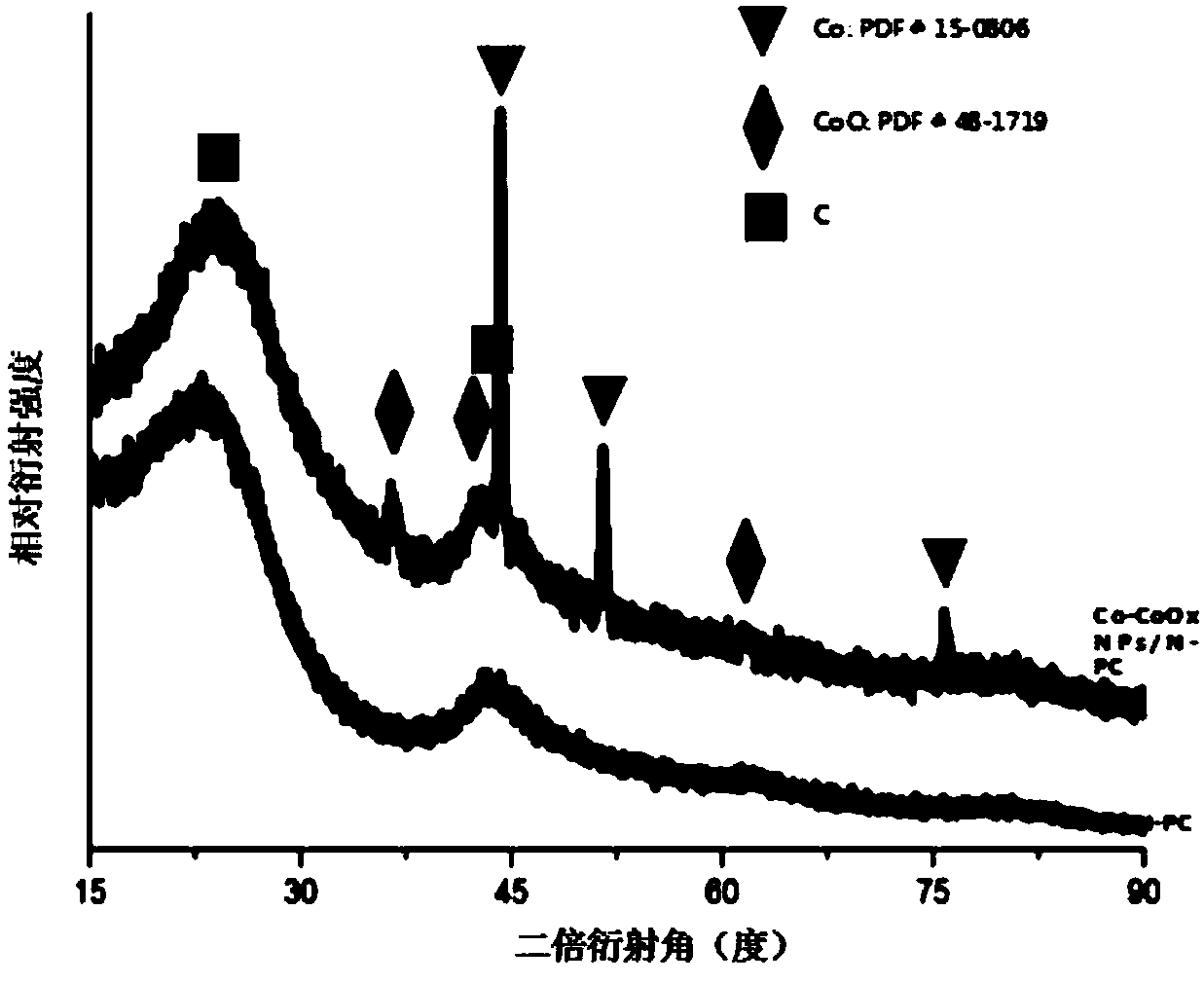

[0047] S4. Under the protection of inert gas, the precursor powder is heated in a tube furnace, chemically calcined and reduced, and then cooled to obtain a supported egg yolk-egg shell nanostructure catalyst for the hydrogenation reaction of p-nitropheno...

Embodiment 1

[0064] A method for preparing a supported egg yolk-egg shell nano-structured catalyst for the hydrogenation reaction of p-nitrophenol includes the following steps:

[0065] S1. Wash the freshly picked holly leaves with deionized water for 3 times, dry them in a blast drying oven at 80°C for 12 hours, then take them out, manually grind them until the leaves are powdered, and sieved through a 100-mesh pharmacopoeia sieve; The tube furnace is heated to 800℃, the heating rate is 10℃ / min, the gas velocity is 40mL / min, and the temperature is maintained for 120min; take 3g of the carbonized holly leaf powder and add it to 80ml of deionized water. After fully stirring on the stirrer, add 2ml of hydrochloric acid and 1ml of nitric acid to it for pickling; set the speed of magnetic stirring to 600r / min, immersion time of 12h; wash with deionized water to PH=7, centrifuge and dry; Under the protection, the tube furnace is heated to 500℃, the heating rate is 10℃ / min, the gas velocity is 40mL...

Embodiment 2

[0075] Except that the sieving pharmacopoeia sieve used in step S1 is 50 meshes, other conditions are the same as in Example 1.

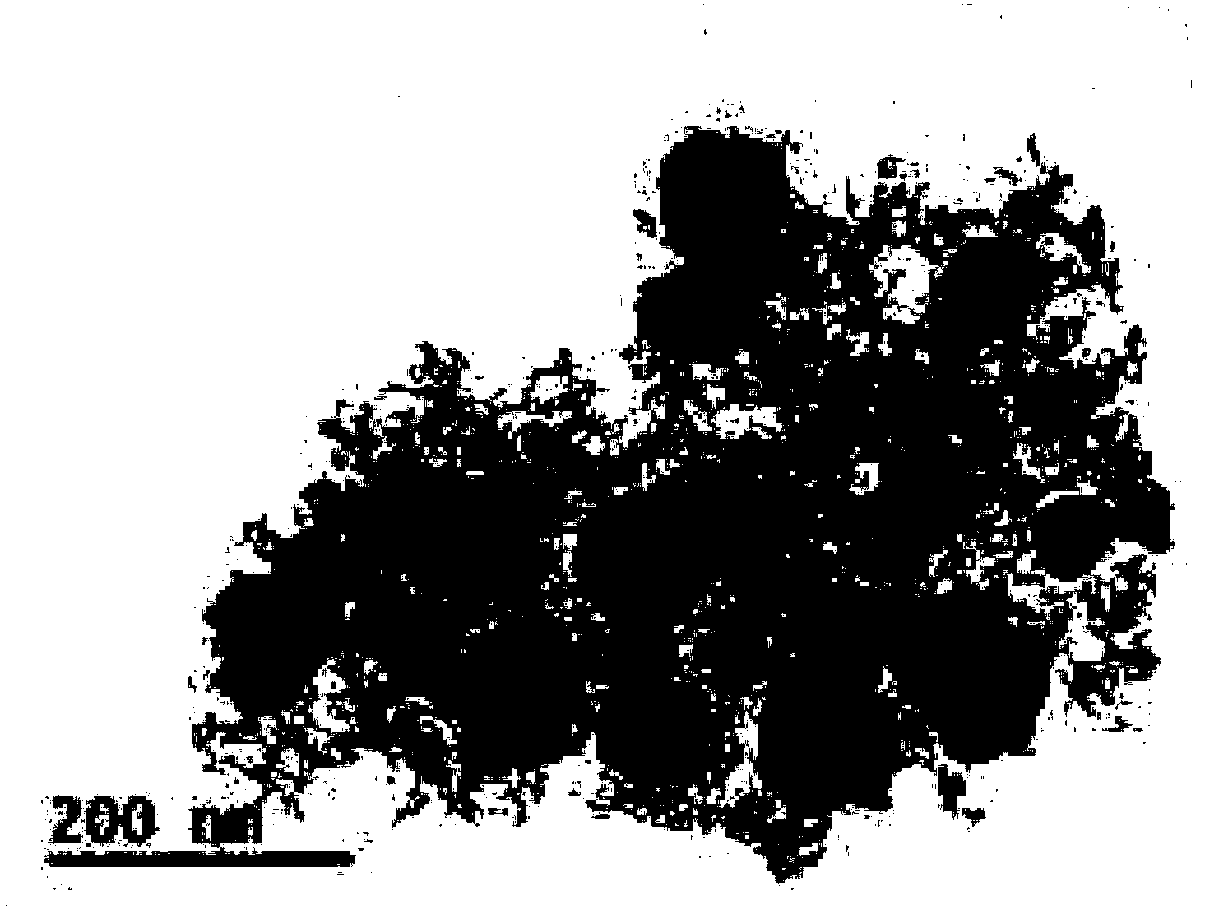

[0076] The obtained supported catalyst has good dispersibility and no agglomeration phenomenon; the average particle size is about 70 nm; all have egg yolk-egg shell structure morphology and uniform distribution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com