Crack-resistant anti-radiation mass concrete based on waste glass and preparation method thereof

A waste glass and large-volume technology, which is applied in the field of construction engineering, can solve the problems of poor shielding effect of gamma rays and poor durability of concrete, and achieve the effects of radiation protection performance, increased difficulty of water movement, and reduced shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

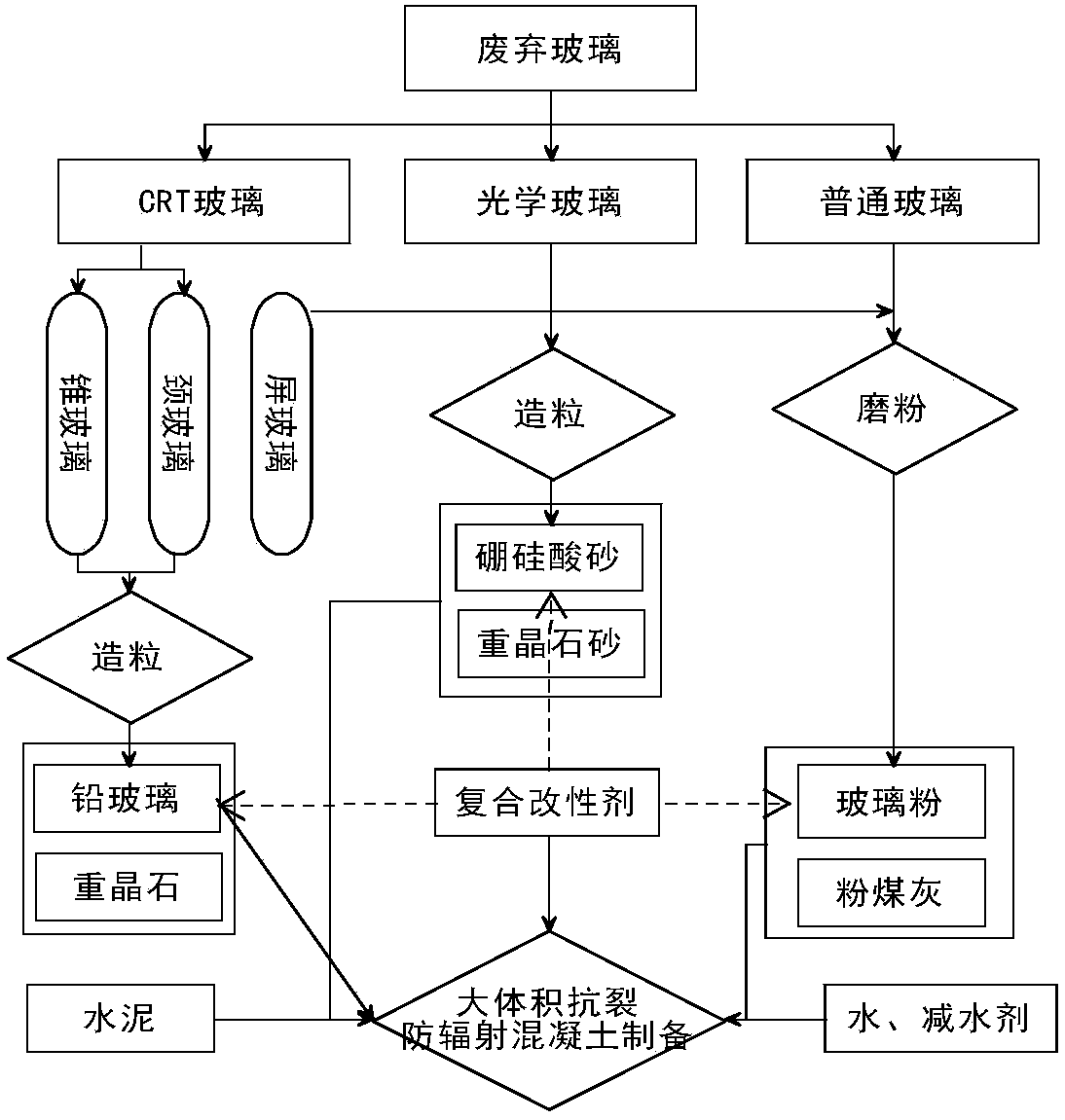

Method used

Image

Examples

Embodiment 1

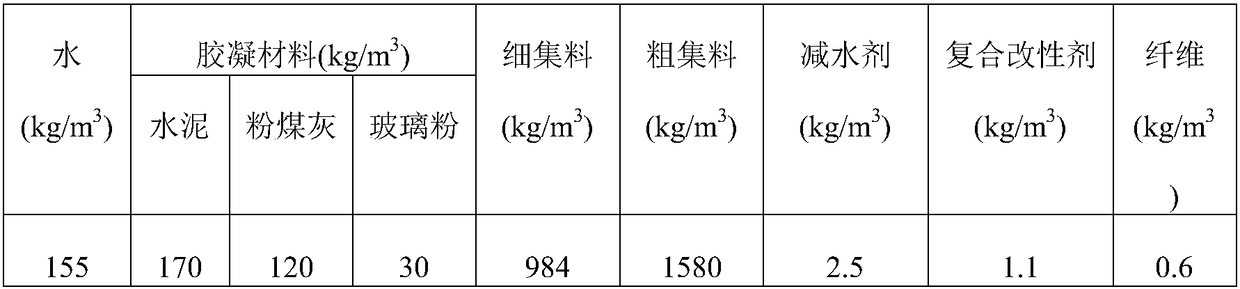

[0034] A large-volume anti-crack and anti-radiation concrete based on waste glass. The components and their contents are shown in Table 1; the coarse aggregate is composed of lead glass aggregate and barite in a mass ratio of 1:2, which is 5-31.5 mm continuous gradation; the fine aggregate is composed of borosilicate glass sand and barite sand in a mass ratio of 1:5, and the fineness modulus of the fine aggregate is 2.5 to 3.0; the mineral admixture is composed of glass powder and powder Coal ash is composed by the mass ratio of 1:4, and the mass ratio of methyl cellulose ether, lithium carbonate, gypsum, slaked lime in the composite modifier is 1:0.5:2:2; The preparation method includes the following steps: mixing the weighed cement, glass powder, fly ash, fine aggregate, coarse aggregate, composite modifier and fiber for 45 seconds to obtain a premixed material; , fiber and water are added to the obtained premixed material according to the stated ratio, and stirred for 150 s...

Embodiment 2

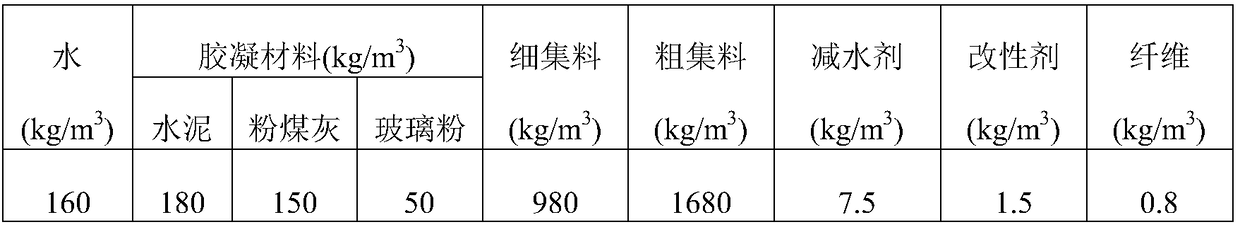

[0038] A large-volume anti-crack and anti-radiation concrete based on waste glass. The components and their contents are shown in Table 2; the coarse aggregate is composed of lead glass aggregate and barite in a mass ratio of 1:3, which is 5 to 31.5 mm continuous gradation; the fine aggregate is composed of borosilicate glass sand and barite sand in a mass ratio of 1:4, and the fineness modulus of the fine aggregate is 2.5 to 3.0; the mineral admixture is composed of glass powder and powder Coal ash is formed by the mass ratio of 1:3, and the mass ratio of methyl cellulose ether, lithium carbonate, gypsum, slaked lime in the composite modifier is 1:0.6:3:2; The preparation method includes the following steps: mixing the weighed cement, glass powder, fly ash, fine aggregate, coarse aggregate, composite modifier and fiber for 45 seconds to obtain a premixed material; , fiber and water are added to the obtained premixed material according to the stated ratio, and stirred for 150 ...

Embodiment 3

[0042] A large-volume anti-crack and anti-radiation concrete based on waste glass. The components and their contents are shown in Table 3; the coarse aggregate is composed of lead glass aggregate and barite in a mass ratio of 1:3, which is 5 to 31.5 mm continuous gradation; the fine aggregate is composed of borosilicate glass sand and barite sand in a mass ratio of 1:3, and the fineness modulus of the fine aggregate is 2.5 to 3.0; the mineral admixture is composed of glass powder and powder Coal ash is formed by the mass ratio of 1:1, and the mass ratio of methyl cellulose ether, lithium carbonate, gypsum, slaked lime in the composite modifier is 1:0.5:5:5; The preparation method includes the following steps: mix the weighed cement, glass powder, fly ash, fine aggregate, coarse aggregate, composite modifier and fiber for 60 seconds to obtain a premixed material; then mix the water reducer , fiber and water are added to the obtained premixed material according to the stated rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com