A kind of manganese-doped inorganic halogen perovskite quantum dot and its preparation method and application

A technology of perovskite and quantum dots, which is applied in the fields of applications, chemical instruments and methods, household appliances, etc., can solve the problems of no double emission, unadjustable wavelength, low quantum yield, etc., achieve short dissolution time and reduce preparation The effect of high cost and solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

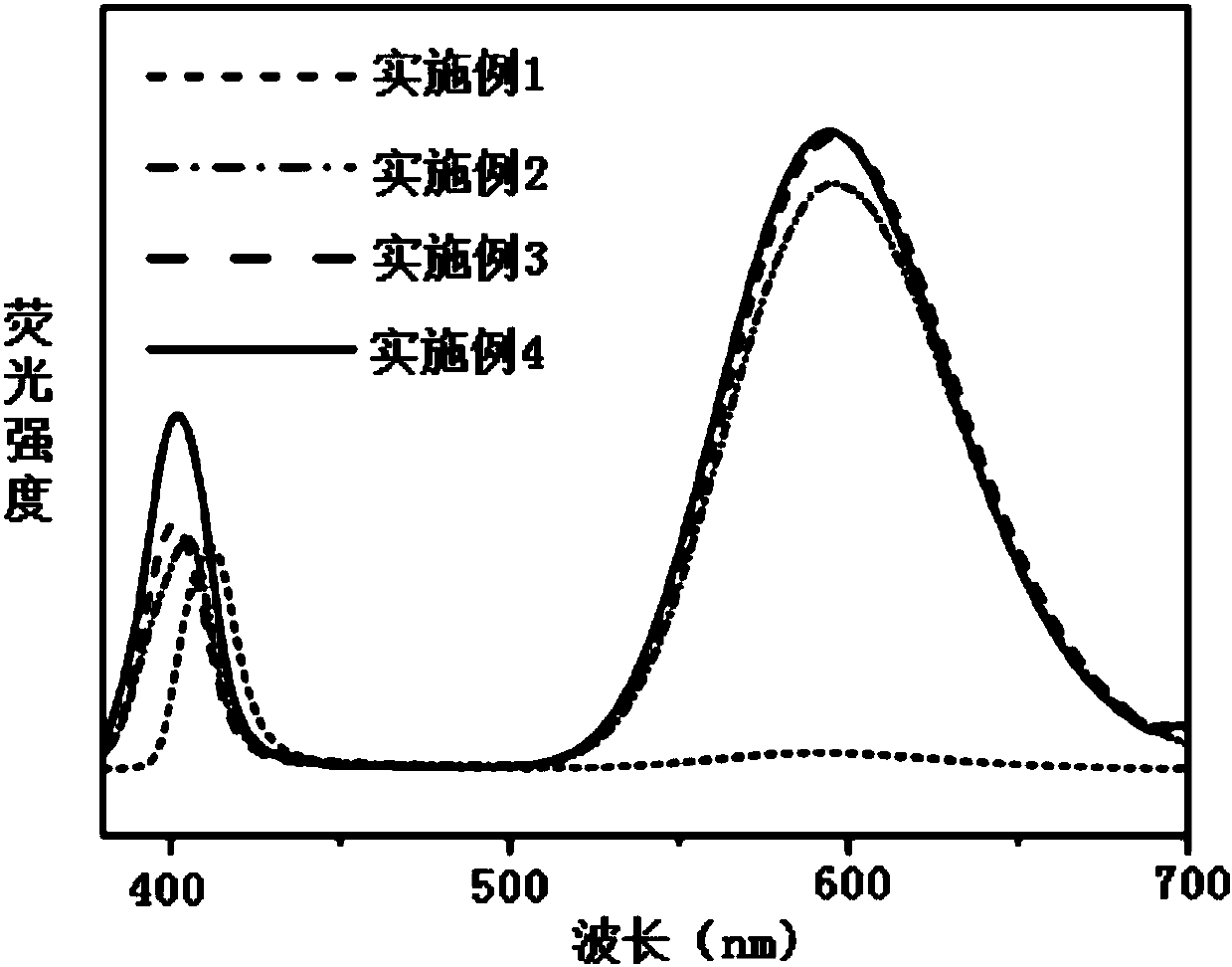

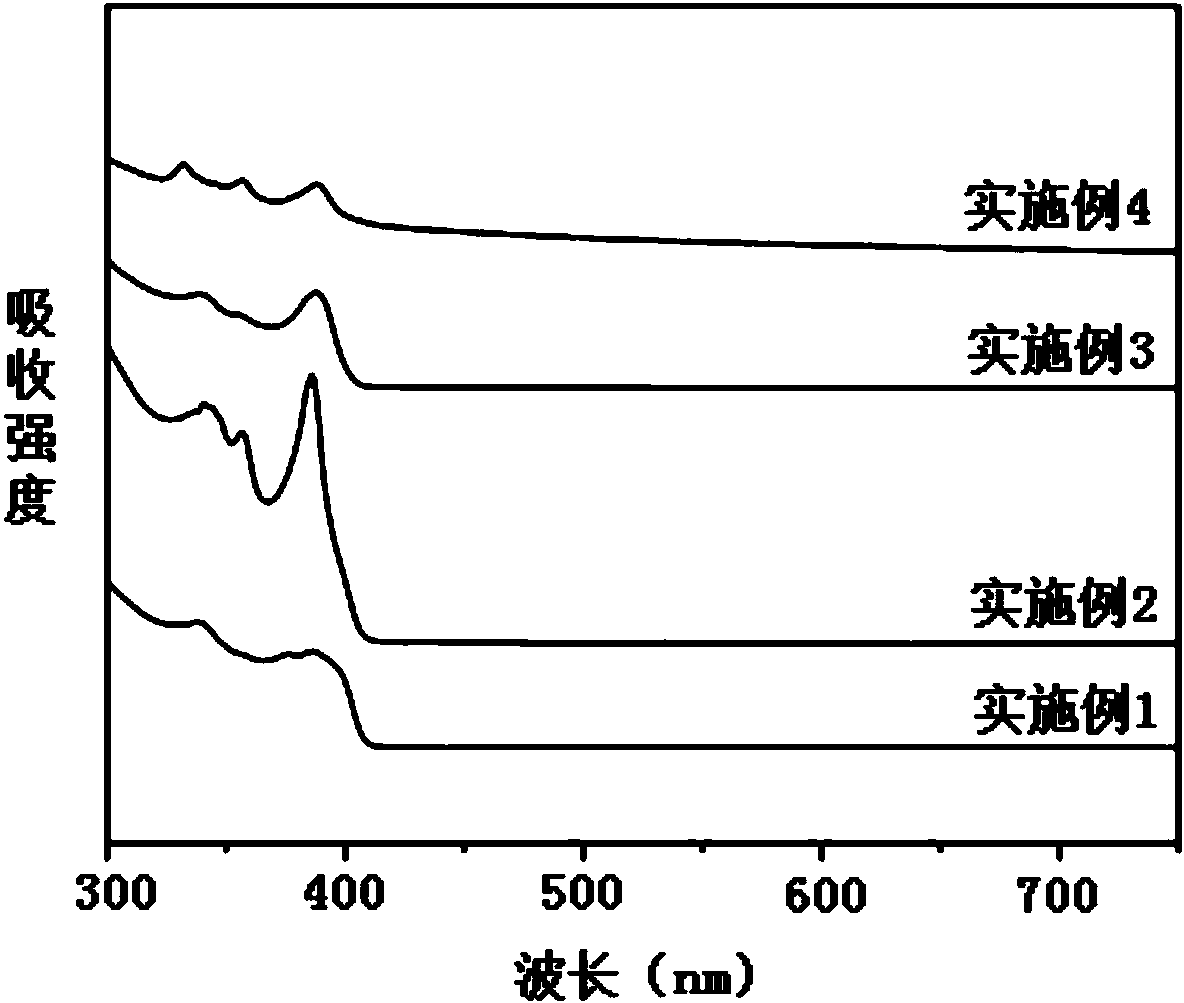

Embodiment 1

[0028] Dissolve 0.943g of CsOAc in 30mL of octadecene, and add 3mL of oleic acid, and keep stirring until completely dissolved to obtain a cesium precursor. 0.455g lead acetate, 0.0755g MnCl 2 Dissolve in 30 mL of octadecene, add 3 mL of oleic acid and 3 mL of oleylamine, heat to 80° C., and keep stirring until completely dissolved to obtain a halogen precursor.

[0029] Take 2mL of the cesium precursor solution and inject it into the halogen precursor, and keep it at 80°C with stirring for 5min. Then the solution is cooled to normal temperature with a water bath, and the luminescent quantum dots containing only halogen chlorine doped with manganese are formed. All operations do not require nitrogen protection and can be operated in the atmosphere.

[0030] Take 5 mL of the quantum dot solution obtained above, add 10 mL of ethyl acetate solution, and then put it into a centrifuge for centrifugation at 8000 rpm for 5 min. Subsequently, the upper solution was discarded, leavi...

Embodiment 2

[0032] Dissolve 0.943g of CsOAc in 30mL of octadecene, and add 3mL of oleic acid, and keep stirring until completely dissolved to obtain a cesium precursor. 0.325g lead acetate, 0.126g MnCl 2 Dissolve in 30 mL of octadecene, add 3 mL of oleic acid and 3 mL of oleylamine, heat to 90° C., and keep stirring until completely dissolved to obtain a halogen precursor.

[0033] Take 2mL of the cesium precursor solution and inject it into the halogen precursor, and keep it at 90°C with stirring for 5min. Then the solution is cooled to normal temperature with a water bath, and the luminescent quantum dots containing only halogen chlorine doped with manganese are formed. All operations do not require nitrogen protection and can be operated in the atmosphere.

[0034] Take 5 mL of the quantum dot solution obtained above, add 10 mL of ethyl acetate solution, and then put it into a centrifuge for centrifugation at 8000 rpm for 5 min. Subsequently, the upper solution was discarded, leavin...

Embodiment 3

[0036] Dissolve 0.943 g of CsOAc in 30 mL of octadecene, add 3 mL of oleic acid, and keep stirring until it is completely dissolved to obtain a cesium precursor. 0.260g lead acetate, 0.151MnCl 2 Dissolve in 30 mL of octadecene, add 3 mL of oleic acid and 3 mL of oleylamine, heat to 100° C., and keep stirring until completely dissolved to obtain a halogen precursor.

[0037] Take 2 mL of the cesium precursor solution and inject it into the halogen precursor, and keep it at 100 °C for 5 min with stirring. Then, the solution was cooled to room temperature with a water bath, and the luminescent quantum dots containing only halogen chlorine-doped manganese were formed. All operations do not require nitrogen protection and can be operated in the atmosphere.

[0038] Take 5 mL of the quantum dot solution obtained above, add 10 mL of ethyl acetate solution, and then put it into a centrifuge for centrifugation at a rotational speed of 8000 rpm and a time of 5 min. Subsequently, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com