A kind of preparation method and application of argan oil microemulsion spray

A technology of microemulsion spray and nut oil, which is applied in the directions of aerosol delivery, anti-inflammatory agent, pharmaceutical formulation, etc., can solve the problem that macadamia nut oil and green bark extract cannot be mutually miscible and used synergistically, and green bark by-products cannot be effectively utilized, Nut oil is easy to oxidize and other problems, to achieve the effect of improving economic added value, simple preparation method and overcoming easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

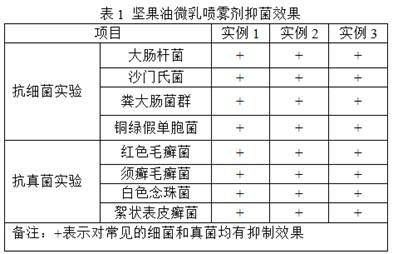

Image

Examples

Embodiment 1

[0023] Embodiment 1 adopts the following steps to realize the present invention:

[0024] (1) Preparation of argan oil nano-microemulsion: Mix Tween 60 and hydrogenated castor oil (mass ratio 2.5:1) as a composite surfactant, and cosurfactant polyethylene glycol and argan oil (mass ratio 1:3.5 ) as a mixed oil phase, and then mix the two at a mass ratio (1:1) to form an emulsion, stir evenly with magnetic force (rotation speed 1200rpm) at 55~70°C, and add distilled water (8 times the mass of the emulsion) dropwise High-speed shear dispersion to obtain W / O nano-emulsion, and then homogenize through a high-pressure micro-fluidic homogenizer (homogenization pressure 50MPa) for 3 times until a transparent and clear nano-emulsion is formed;

[0025] (2) Preparation of macadamia nut green peel extract: take macadamia nut green peel powder with a particle size of 100 mesh and 8 times the mass of macadamia nut green peel powder with a volume fraction of 70% edible alcohol, mix them, a...

Embodiment 2

[0027] Embodiment 2 adopts the following steps to realize the present invention:

[0028] (1) Preparation of argan oil nano-microemulsion: Mix Tween 60 and hydrogenated castor oil (mass ratio 2.5:1) as a composite surfactant, and cosurfactant polyethylene glycol and argan oil (mass ratio 1:3.5 ) as a mixed oil phase, and then mix the two at a mass ratio (1:1) to form an emulsion, stir evenly with magnetic force (rotation speed 1200rpm) at 55~70°C, and add distilled water (10 times the mass of the emulsion) dropwise High-speed shear dispersion to obtain W / O nano-emulsion, and then homogenized by a high-pressure micro-fluidic homogenizer (homogenization pressure 60MPa) 4 times until a transparent and clear nano-emulsion is formed;

[0029] (2) Preparation of macadamia nut green peel extract: take macadamia nut green peel powder with a particle size of 100 mesh and 6 times the mass of macadamia nut green peel powder with a volume fraction of 70% edible alcohol, mix them, and extr...

Embodiment 3

[0031] Embodiment 3 Adopt the following steps to realize the present invention:

[0032] (1) Preparation of argan oil nano-microemulsion: Mix Tween 60 and hydrogenated castor oil (mass ratio 2.5:1) as a composite surfactant, and cosurfactant polyethylene glycol and argan oil (mass ratio 1:3.5 ) as a mixed oil phase, and then mix the two at a mass ratio (2:1) to form an emulsion, stir evenly with magnetic force (rotation speed 1200rpm) at 55~70°C, and add distilled water (12 times the mass of the emulsion) dropwise High-speed shear dispersion to obtain W / O nano-emulsion, and then homogenized by a high-pressure micro-jet homogenizer (homogeneous pressure 80MPa) for 3 to 5 times until a transparent and clear nano-emulsion is formed;

[0033](2) Preparation of macadamia nut green peel extract: take macadamia nut green peel powder with a particle size of 200 mesh and 10 times the mass of macadamia nut green peel powder with a volume fraction of 70% edible alcohol, mix them, and ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com