Method for preparing organic fertilizer through agricultural and animal husbandry waste

A technology of waste and organic fertilizer, applied in the field of preparing organic fertilizer by using agricultural and animal husbandry waste, can solve the problems of breeding mosquitoes and flies, polluting living environment, large amount of agricultural waste, etc., to promote rapid growth, promote rapid rooting, The effect of improving fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

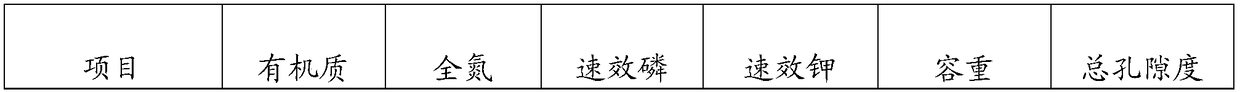

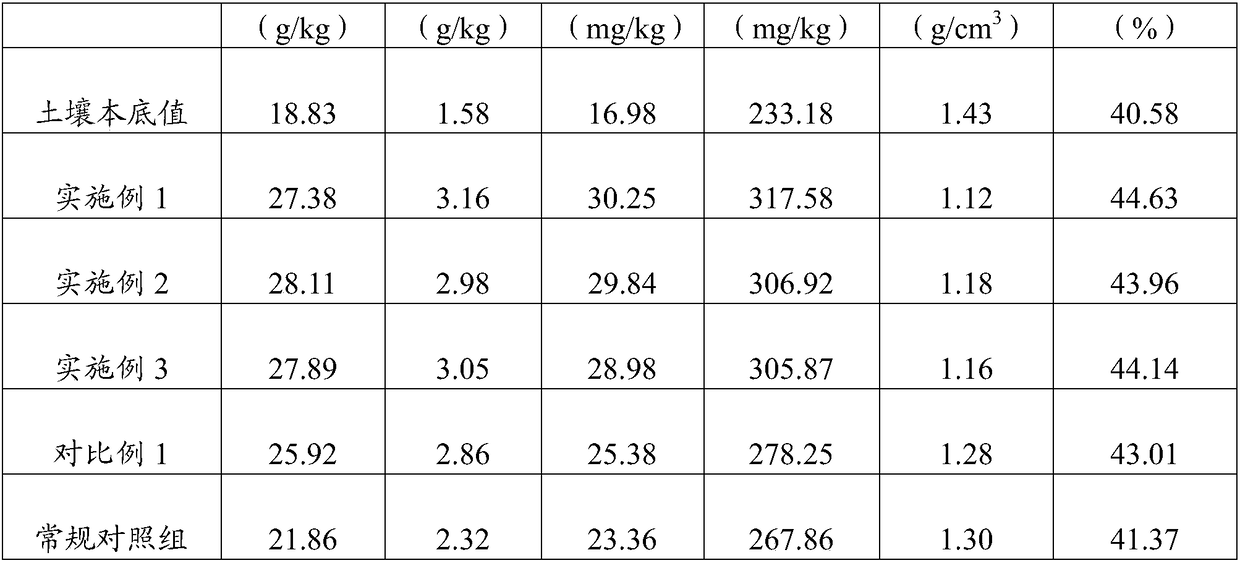

Examples

Embodiment 1

[0028] A method for preparing organic fertilizer from agricultural and animal husbandry waste, specifically prepared according to the following steps:

[0029] Step 1, crushing the crop waste into 3-5cm segments to obtain the crop waste slag;

[0030] Step 2, mix the giant fungus grass and willow branches and leaves according to the mass ratio of 5:1, and then crush them into 0.5-1cm segments to obtain the nutrient residue; add acetic acid equivalent to 5 times the weight of the nutrient residue to the nutrient residue Soak in sodium acetate buffer solution for 60 minutes, then add compound enzyme equivalent to 1% of the weight of nutrient slag to it, enzymolyze at 40°C for 8 hours, and obtain the enzymolysis product after enzymolysis is completed;

[0031] Among them, the compound enzyme is prepared by mixing protease, cellulase and xylanase according to the mass ratio of 1:2:1;

[0032] Step 3, mix the agricultural waste material slag in step 1, the enzymatic hydrolysis pro...

Embodiment 2

[0037] A method for preparing organic fertilizer from agricultural and animal husbandry waste, specifically prepared according to the following steps:

[0038] Step 1, crushing the crop waste into 3-5cm segments to obtain the crop waste slag;

[0039] Step 2, mix the giant fungus grass and willow branches and leaves according to the mass ratio of 5:1, and then crush them into 0.5-1cm segments to obtain the nutrient residue; add acetic acid equivalent to 5 times the weight of the nutrient residue to the nutrient residue Soak in sodium acetate buffer solution for 60 minutes, then add compound enzyme equivalent to 1% of the weight of nutrient slag to it, enzymolyze at 50°C for 6 hours, and obtain the enzymolysis product after enzymolysis is completed;

[0040] Among them, the compound enzyme is prepared by mixing protease, cellulase and xylanase according to the mass ratio of 1:2:1;

[0041] Step 3, mix the agricultural waste material slag in step 1, the enzymatic hydrolysis pro...

Embodiment 3

[0046] A method for preparing organic fertilizer from agricultural and animal husbandry waste, specifically prepared according to the following steps:

[0047] Step 1, crushing the crop waste into 3-5cm segments to obtain the crop waste slag;

[0048] Step 2, mix the giant fungus grass and willow branches and leaves according to the mass ratio of 5:1, and then crush them into 0.5-1cm segments to obtain the nutrient residue; add acetic acid equivalent to 5 times the weight of the nutrient residue to the nutrient residue Soak in sodium acetate buffer solution for 60 minutes, then add compound enzyme equivalent to 1% of the weight of nutrient slag to it, enzymolyze at 60°C for 5 hours, and obtain the enzymolysis product after enzymolysis is completed;

[0049] Among them, the compound enzyme is prepared by mixing protease, cellulase and xylanase according to the mass ratio of 1:2:1;

[0050] Step 3, mix the agricultural waste material slag in step 1, the enzymatic hydrolysis pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com