Preparation method of porphyra yezoensis antioxidant protein peptide

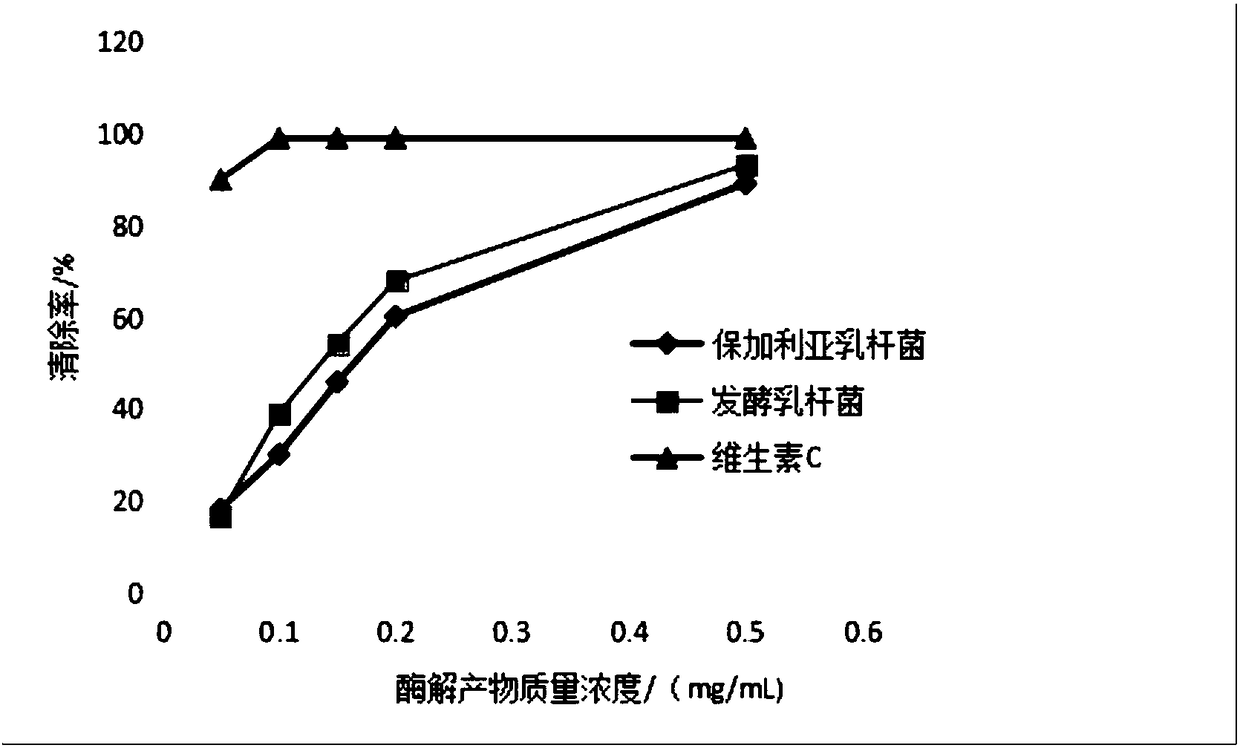

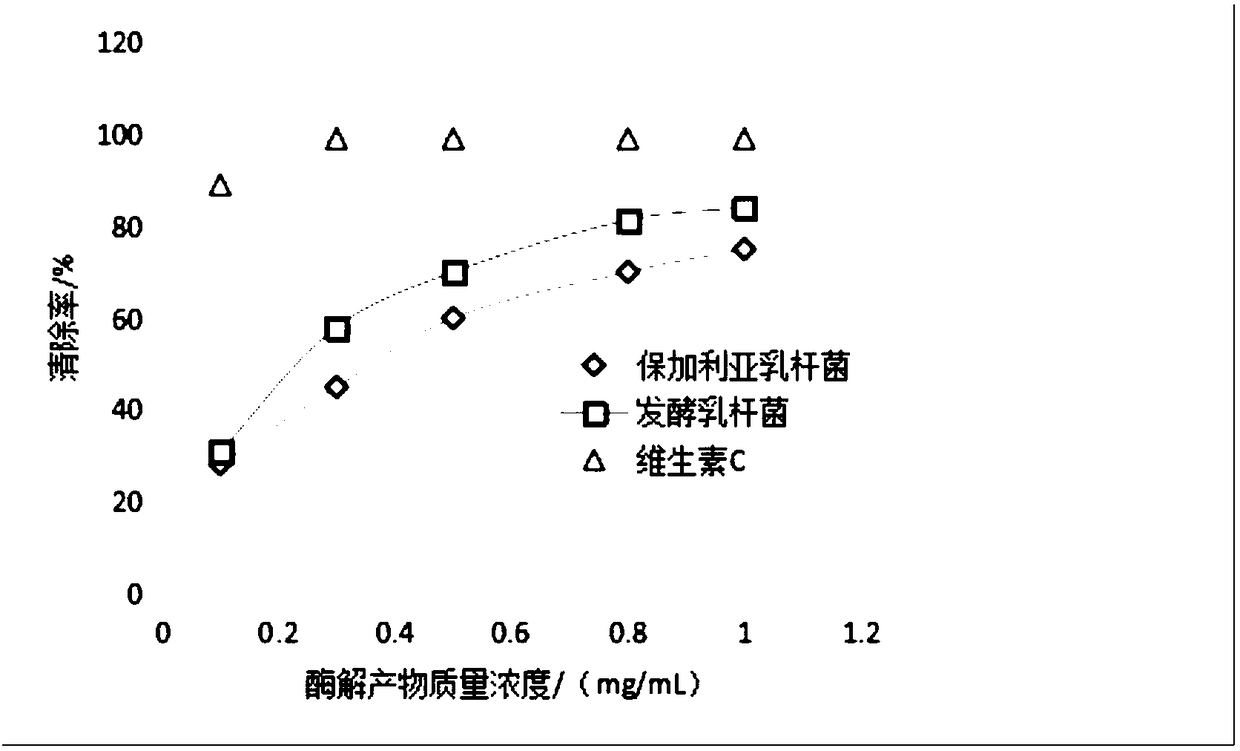

An anti-oxidative protein and Porphyra zebra technology, which is applied to the preparation method of peptides, biochemical equipment and methods, chemical instruments and methods, etc., can solve the problems of poor palatability, heavy peptide bitterness, and low peptide yield, and achieve improved Good removal ability, palatability, and value-added effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of Porphyra zebra antioxidant protein peptide, comprising the following steps:

[0027] S100, using Porphyra variegata as a raw material to perform crushing treatment, water extraction, and sterilization treatment to obtain an extract;

[0028] S200, inoculating the obtained extraction solution with lactic acid bacteria for fermentation, the inoculation amount of lactic acid bacteria is 1%-3%, the fermentation temperature is 35°C-40°C, the fermentation time is 20-36 hours, and the mixed solution is sterilized after fermentation;

[0029] S300, enzymatically hydrolyzing the sterilized mixed solution with papain, the addition amount is 0.5%-2% of the mass of Porphyra variegata, the enzymolysis temperature is 55°C-65°C, and the enzymolysis reaction time is 2-4 hours; After enzymatic hydrolysis, carry out inactivation treatment, after cooling, carry out centrifugation, and collect the supernatant;

[0030] Among them, the enzyme ...

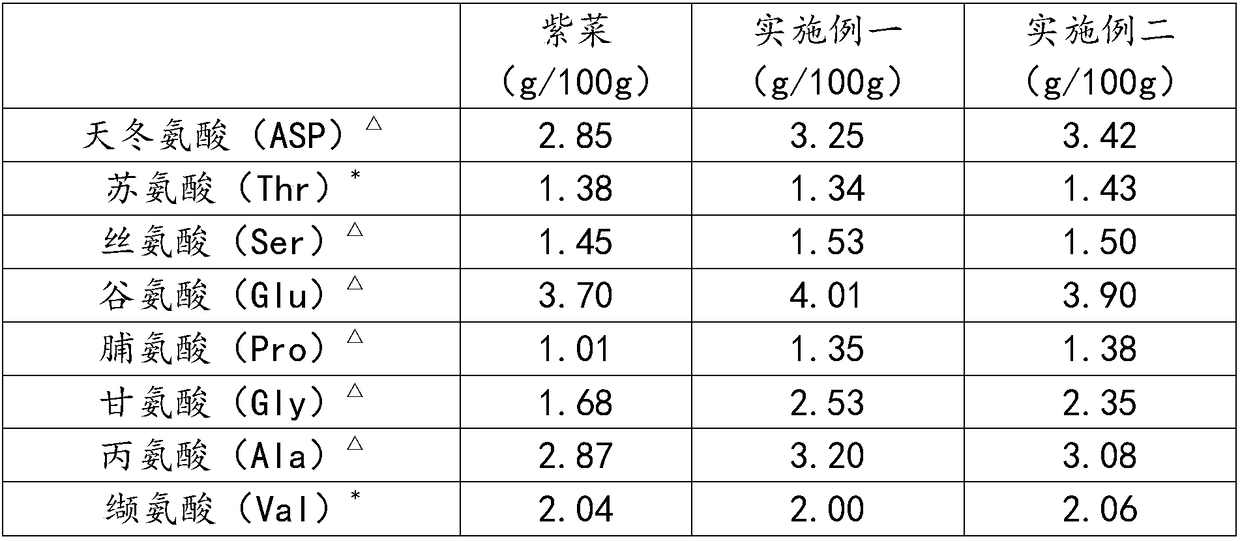

Embodiment 1

[0043] S100. Take 20g of Porphyra zebra and crush it with a 40-mesh sieve and add 500mL of distilled water to mix; stir for 20 minutes for leaching; after leaching, treat the extract at 121°C for 10 minutes to kill pathogenic bacteria and cool to Standby at 40°C;

[0044] S200, inoculate Lactobacillus bulgaricus in fresh MRS medium, activate for 12 hours, culture temperature is 37°C, shaker speed is 200 rpm;

[0045] Inoculate the above-mentioned activated culture solution into the extraction solution prepared by S100; the inoculation amount of Lactobacillus bulgaricus is 3%, the fermentation temperature is 37°C, and the fermentation time is 36 hours; after fermentation, the mixed solution is heated at 90°C for 10 minutes heat treatment.

[0046] S300, add 0.3g papain (2×105U / g), enzymolysis temperature is 60°C, enzymolysis reaction is 4 hours; after enzymolysis, at 100°C, treatment time is 15min for inactivation; after natural cooling , centrifuge at 5000r / min for 15 minute...

Embodiment 2

[0049] S100. Take 20g of Porphyra zebra and crush it with a 40-mesh sieve and add 500mL of distilled water to mix; stir for 20 minutes for leaching; after leaching, treat the extract at 121°C for 10 minutes to kill pathogenic bacteria and cool to Standby at 40°C;

[0050] S200. Inoculate Lactobacillus fermentum into fresh MRS medium, activate for 12 hours, culture temperature is 37°C, shaker speed is 200 rpm;

[0051] Inoculate the above-mentioned activated culture solution into the extraction solution prepared by S100; the inoculation amount of Lactobacillus fermentum is 3%, the fermentation temperature is 37°C, and the fermentation time is 36 hours; after fermentation, the mixed solution is heated at 90°C for 10 minutes heat treatment.

[0052] S300, add 0.3g papain (2×105U / g), enzymolysis temperature is 60°C, enzymolysis reaction is 4 hours; after enzymolysis, at 100°C, treatment time is 15min for inactivation; after natural cooling , centrifuge at 5000r / min for 15 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com