Biodegradable triblock miktoarm star-shaped amphiphilic high molecular material and preparation method thereof

A polymer material and biodegradable technology, applied in the field of biodegradable multi-arm star-shaped amphiphilic polymer materials and their preparation, can solve the problems of small hydrodynamic radius, low viscosity, and difficult preparation, and achieve low Effects of critical material concentration, high stability, and high drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

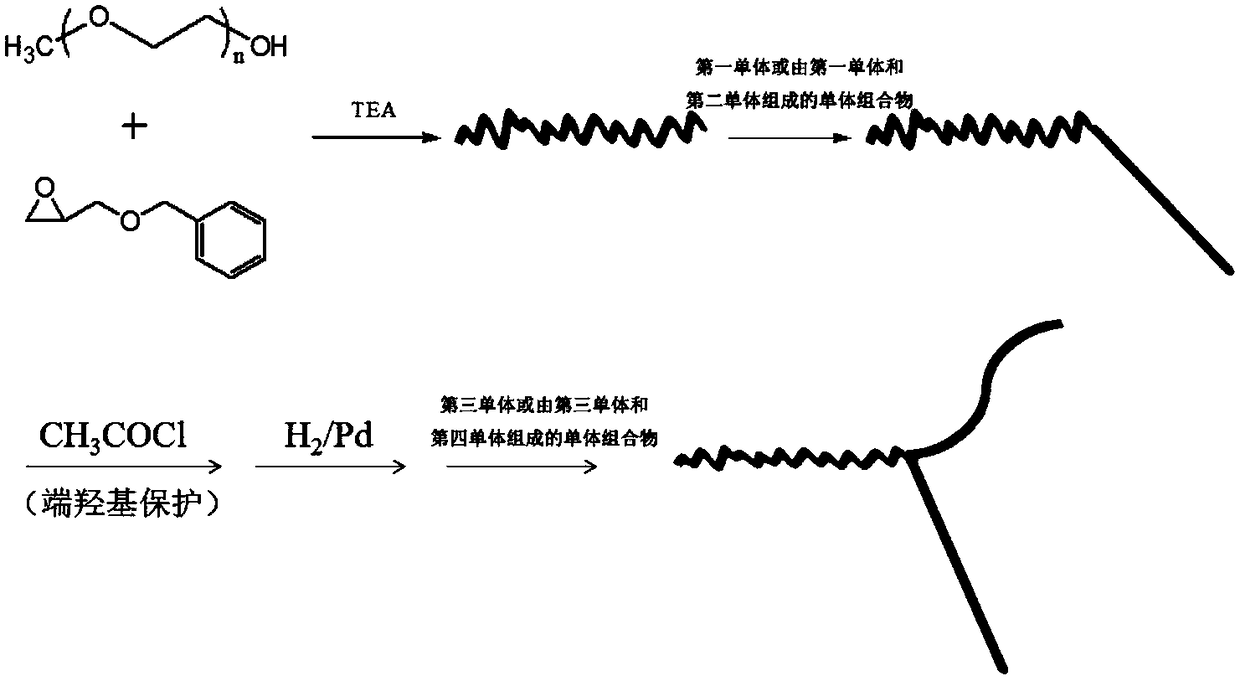

[0041] This example prepares PCL-PEG-PLLA biodegradable triblock heteroarm star-shaped amphiphilic polymer material, and the preparation steps are as follows:

[0042] (1) End group modification of mPEG

[0043] First feed nitrogen into the branch bottle for 5 minutes, then under the protection of nitrogen, add 6 g of vacuum-dried polyethylene glycol monomethyl ether (Mn=2000) in the branch bottle, and add 30 ml of dichloromethane, and stir until Dissolve to obtain a dichloromethane solution of polyethylene glycol monomethyl ether; then add 2.29 mL of benzyloxymethyl oxirane to the dichloromethane solution of polyethylene glycol monomethyl ether and mix to obtain the first mixed solution, and then Under the conditions of ice bath and magnetic stirring, add a dichloromethane solution of triethylamine dropwise into the obtained first mixed solution (obtained by mixing 4.17mL triethylamine and 10mL dichloromethane uniformly), after the dropwise addition, the The bottle was moved...

Embodiment 2

[0055] In this example, PCL-PEG-PGA biodegradable triblock heteroarm star-shaped amphiphilic polymer material is prepared, and the preparation steps are as follows:

[0056] (1) End group modification of mPEG

[0057] First pass nitrogen into the branch bottle for 10 minutes, then under the protection of nitrogen, add 8 g of vacuum-dried polyethylene glycol monomethyl ether (Mn=2000) into the branch bottle, and add 30 ml of chloroform, stir until dissolved, Obtain a chloroform solution of polyethylene glycol monomethyl ether; then add 0.61 mL of benzyloxymethyl oxirane to the chloroform solution of polyethylene glycol monomethyl ether and mix to obtain the first mixed solution, then in an ice bath, magnetically stirred Under the conditions, drop the chloroform solution of triethylamine (obtained by mixing 0.56mL triethylamine and 15mL chloroform) into the obtained first mixed solution dropwise. React for 1 day; after the reaction, the reaction solution obtained by rotary stea...

Embodiment 3

[0067] This example prepares PVL-PEG-PLLA biodegradable triblock heteroarm star-shaped amphiphilic polymer material, and the preparation steps are as follows:

[0068] (1) End group modification of mPEG

[0069] First pass nitrogen into the branch bottle for 3 minutes, then under the protection of nitrogen, add 5 g of vacuum-dried polyethylene glycol monomethyl ether (Mn=5000) into the branch bottle, and add 100 ml of tetrahydrofuran, stir until dissolved, To obtain a tetrahydrofuran solution of polyethylene glycol monomethyl ether; then add 1.52 mL of benzyloxymethyl oxirane to the tetrahydrofuran solution of polyethylene glycol monomethyl ether and mix to obtain the first mixed solution, then in an ice bath and magnetically stirred Under the conditions, drop triethylamine tetrahydrofuran solution (obtained by uniformly mixing 1.39mL triethylamine and 10mL tetrahydrofuran) into the obtained first mixed solution. Reacted for 2 days; after the reaction, the reaction solution o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com