Preparation method of polymer modified graphene composite material

A graphene composite and composite material technology, which is applied in the field of preparation of polymer-modified graphene composite materials, can solve problems such as bonding, graphene dispersion interface, and distance, and achieves simple preparation process and improved tensile modulus. , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

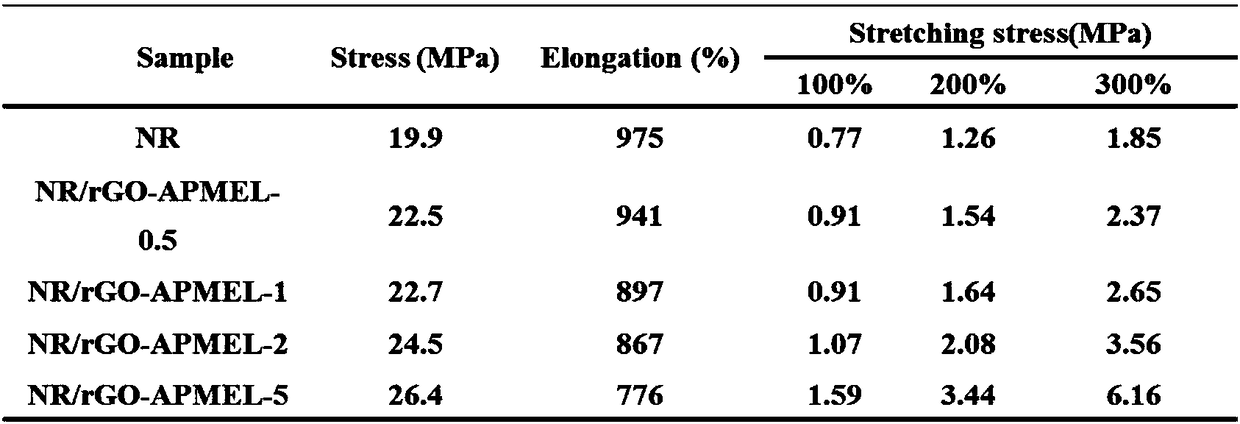

Examples

Embodiment 1

[0034] Add 3.0kg of graphite oxide and 1600kg of water into the ultrasonic irradiation reactor, and ultrasonically disperse for 2 hours under the conditions of ultrasonic power of 300W, frequency of 300Hz, and temperature of 50°C to obtain a graphite oxide solution, and add 1kg of triethylenetetramine, continued to ultrasonically disperse for 1 hour, then stirred and reacted at 40°C for 20 hours, then centrifuged and washed at a speed of 10,000r / min, washed until neutral, and finally dried at 80°C to constant weight to obtain Modified graphene;

[0035] Add 2.5kg of modified graphene and 1600kg of water into a reaction kettle with an ultrasonic generator, the ultrasonic power is 200W, the frequency is 200Hz, the temperature is 40°C, ultrasonically disperse for 1 hour to obtain a modified graphene solution, and add natural rubber latex 32.3kg, continue to ultrasonically disperse for 1 hour to obtain a natural latex / modified graphene composite emulsion; use 5kg of formic acid de...

Embodiment 2

[0039] Add 100kg of modified graphene and 3000kg of ethanol into the ultrasonic cleaning machine, and the ultrasonic time is 1.5 hours to obtain a modified graphene solution, add 300 kg of polymethyl methacrylate emulsion, ultrasonic 1.5 hours, then add 8 kg of sodium borohydride solution, Continue ultrasonication for 2 hours to obtain polymethyl methacrylate / modified graphene composite emulsion. Using 30kg of sodium chloride solution, at a temperature of 100°C, demulsification for 60 minutes, and drying the product to a constant weight at a vacuum degree of 0.1MPa and a temperature of 230°C to obtain a polymethyl methacrylate / modified graphene composite masterbatch.

[0040] 34kg polymethyl methacrylate-coated modified graphene, 70kg polymethyl methacrylate, 13kg bis(tribromophenoxy)ethane and 7kg PbO3 were prepared by extrusion Ester / modified graphene composite material, extrusion temperature is 200°C.

Embodiment 3

[0042] Add 0.01kg of modified graphene and 100kg of DMF into the ultrasonic irradiation reactor, start the ultrasonic cell pulverizer, the ultrasonic power is 10000W, the frequency is 20000Hz, the temperature is 60°C, and the ultrasonic dispersion time is 30 minutes to obtain a modified graphene solution. Add 5 kg of EVA latex, continue ultrasonication for 30 minutes, then add 4 kg of ethylenediamine, and continue ultrasonication for 3 hours to prepare a stable EVA / modified graphene composite emulsion. Using 1kg of sodium sulfate solution, demulsification at a temperature of 10°C for 1 minute, and drying the product to a constant weight at a vacuum degree of 0.05MPa and a temperature of 50°C to obtain an EVA / modified graphene composite masterbatch.

[0043] 21kg of EVA-coated modified graphene, 80kg of EVA, 20kg of calcium carbonate and 3kg of stearic acid were first extruded and mixed uniformly through a twin-screw extruder, and the extrusion temperature was 180°C. After gran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com