A kind of graphene-metal sulfide-polymer composite fiber membrane with layered structure and its preparation method

A metal sulfide, composite fiber membrane technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as rare research on textile materials, achieve good biodegradability, high binding force, and improve compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

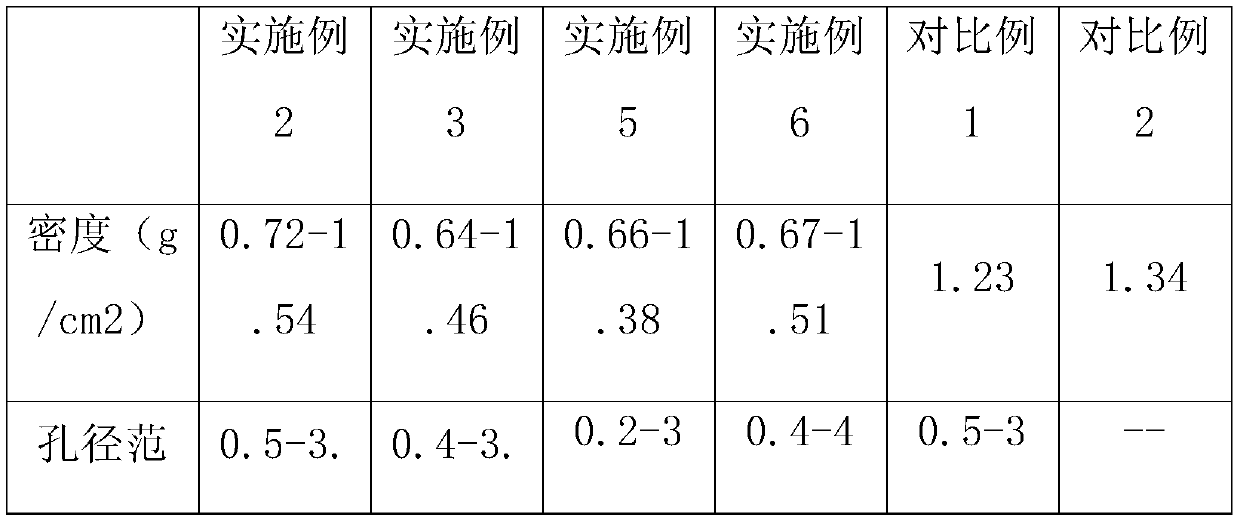

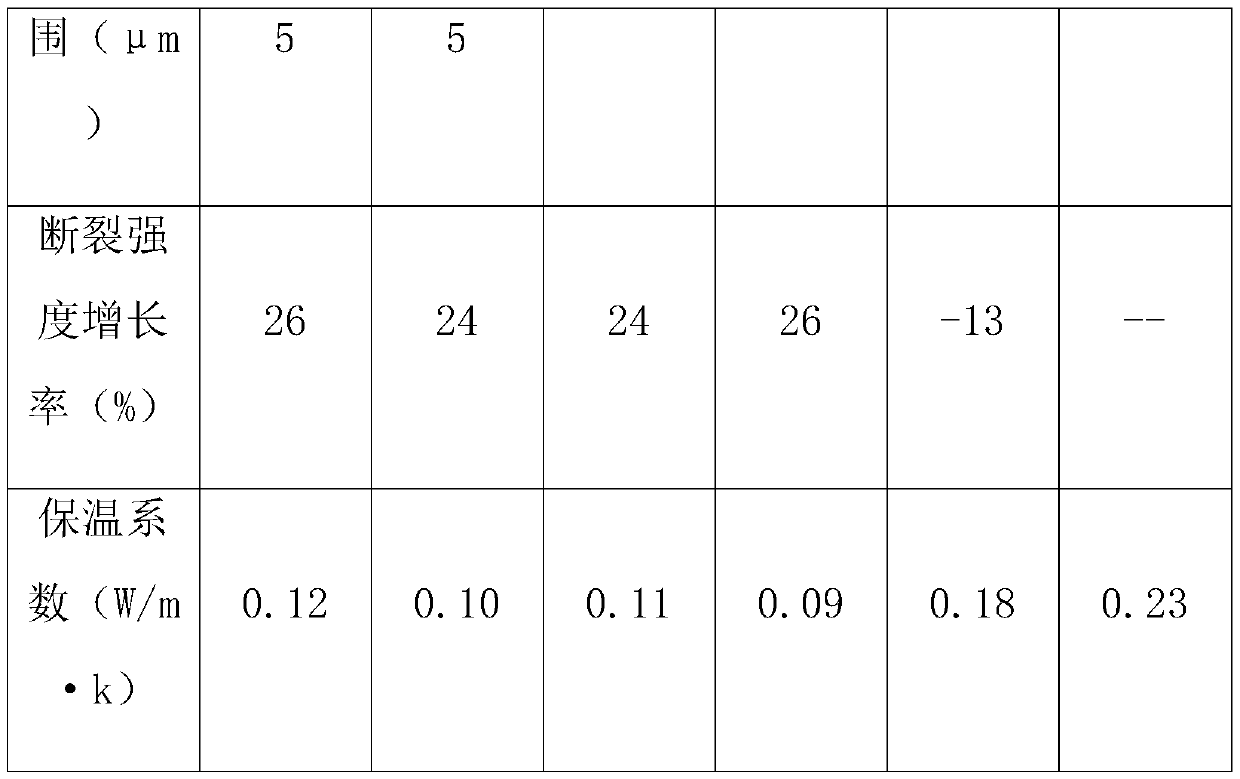

Embodiment 2

[0025] (1) According to the mass ratio of graphene oxide, metal ion, PVP and sulfur powder is 1:0.2:0.5:0.4, add 5wt% metal iron / chromium / aluminum / molybdenum ion solution in the graphene oxide aqueous solution of 20mg / L 1. PVP and sulfur powder with a molecular weight of 1.3 million, after mixing evenly, adding alkaline solution dropwise, heating and pressurizing at 240°C and 1MPa for 24 hours, washing and drying to obtain a graphene-coated metal sulfide nanocomposite material.

[0026] (2) Add the graphene-coated metal sulfide nanocomposite to the bacterial cellulose solution, induce culture at 32°C for 2 days, and obtain a translucent bacterial cellulose film-coated nanocomposite, in which the translucent bacterial cellulose The thickness of the translucent bacterial cellulose film in the nanocomposite coated with plain film is 500 μm.

[0027] (3) Add the nanocomposite material coated with translucent bacterial cellulose film to the polyethylene polymer, after heating and m...

Embodiment 3

[0029] (1) According to the mass ratio of graphene oxide, metal ion, PVP and sulfur powder is 1:0.15:0.4:0.3, add 3wt% metal aluminum ion solution in the graphene oxide aqueous solution of 17mg / L, molecular weight is 1,300,000 After the PVP and sulfur powder are mixed evenly, the alkaline solution is added dropwise, heated and pressurized at 230 °C and 0.6 MPa for 20 hours, washed and dried to obtain a graphene-coated metal sulfide nanocomposite.

[0030] (2) Add the graphene-coated metal sulfide nanocomposite to the bacterial cellulose solution, induce culture at 30°C for 1.5 days, and obtain a translucent bacterial cellulose film-coated nanocomposite, in which the translucent bacteria The thickness of the translucent bacterial cellulose film in the cellulose film-coated nanocomposite was 100 μm.

[0031](3) Add translucent bacterial cellulose film-coated nanocomposites to the polylactic acid polymer, heat and melt, use a layered receiver in the electrospinning device, the sp...

Embodiment 5

[0033] (1) According to the mass ratio of graphene oxide, metal ion, PVP and sulfur powder is 1:0.1:0.5:0.2, add 2wt% metal molybdenum ion solution in the graphene oxide aqueous solution of 20mg / L, molecular weight is 1,300,000 After the PVP and sulfur powder are mixed evenly, the alkaline solution is added dropwise, heated and pressurized at 200 ° C and 1 MPa for 18 hours, washed and dried to obtain a graphene-coated metal sulfide nanocomposite.

[0034] (2) Add the graphene-coated metal sulfide nanocomposite to the bacterial cellulose solution, induce culture at 32°C for 1 day, and obtain a translucent bacterial cellulose film-coated nanocomposite, in which the translucent bacterial cellulose The thickness of the translucent bacterial cellulose film in the nanocomposite coated with plain film was 350 μm.

[0035] (3) Add the nanocomposite material coated with translucent bacterial cellulose film to the polyethylene polymer, after heating and melting, in the electrospinning d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com