Antimony-cerium modified molybdenum disulfide/indium oxide quaternary gas sensitive material and preparation method thereof

A technology of molybdenum disulfide and gas-sensing materials, which is applied in the field of preparation of sensor gas-sensing materials, can solve problems such as being easily oxidized, and achieve the effects of improving conductivity, high specific surface area, and increasing specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of antimony-cerium modified molybdenum disulfide / indium oxide gas sensitive material includes the following steps:

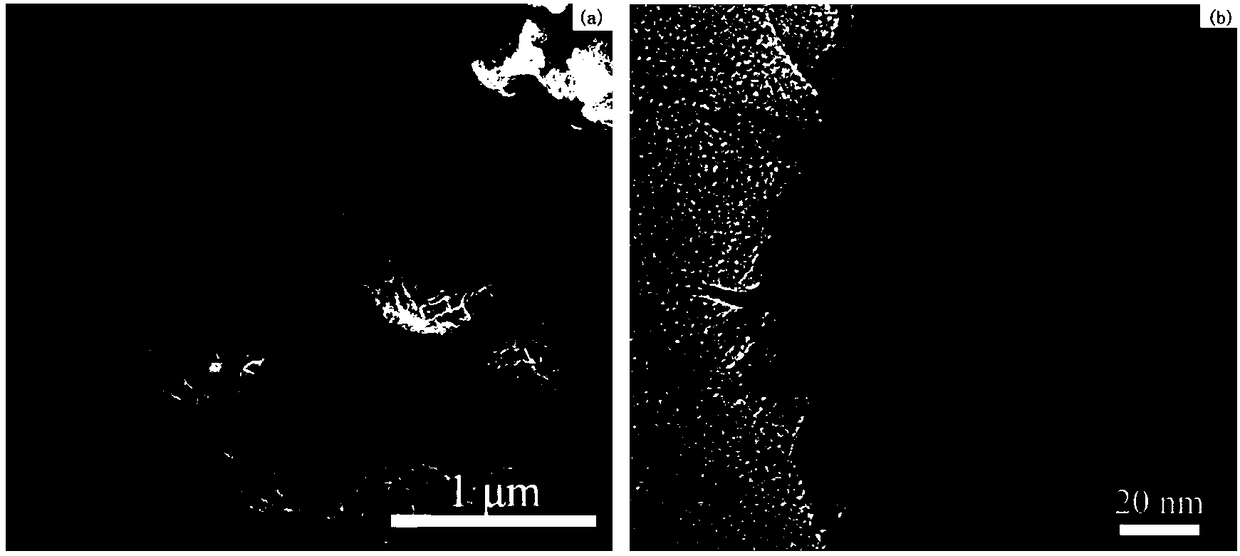

[0037] (1) Hydrothermal synthesis of MoS 2 / In 2 O 3 Nanocomposites: 1) Dissolve 1mmol of sodium molybdate, 4mmol of thiourea, and 1mmol of citric acid in 50ml of water, and hydrothermally react at 200℃ for 21h to obtain MoS 2 , As In 2 O 3 Carrier; 2) 1mmolMoS 2 Carrier and 3mmol In 2 O 3 Mix, in 180℃, 18 hours of hydrothermal conditions 2 O 3 Nanoparticles dispersed into MoS 2 The surface of the lamella is obtained;

[0038] (2) In an argon protective atmosphere, use 0.06mmol of antimony trichloride and 0.06mmol of cerium nitrate as the source of antimony and cerium respectively, and the MoS in step (1) 2 / In 2 O 3 Nanocomposite material mixing (the amount of antimony source and cerium source added is: Sb: Ce: In 2 O 3 The molar ratio of is 0.01:0.01:1), hydrothermally reacted at 180℃ for 16h, then centrifuged and dried the product for lat...

Embodiment 2

[0041] A preparation method of antimony-cerium modified molybdenum disulfide / indium oxide gas sensitive material includes the following steps:

[0042] (1) Hydrothermal synthesis of MoS 2 / In 2 O 3 Nanocomposite materials: 1) Dissolve 2mmol of sodium molybdate, 8mmol of thiourea, and 2mmol of citric acid in 50ml of water and hydrothermally react at 200℃ for 18h to obtain MoS 2 , As In 2 O 3 Carrier; 2) 2mmolMoS 2 Carrier and 4mmol In 2 O 3 Mixing, the In 2 O 3 Nanoparticles dispersed into MoS 2 The surface of the lamella is obtained;

[0043] (2) In an argon protective atmosphere, use 0.02mmol of antimony trichloride and 0.02mmol of cerium nitrate as the source of antimony and cerium, respectively, and the MoS in step (1) 2 / In 2 O 3 Nanocomposite material mixing (the amount of antimony source and cerium source added is: Sb: Ce: In 2 O 3 The molar ratio is 0.01:0.01:10), hydrothermally reacted at 240℃ for 24h, then centrifuged, dried the product, and set aside;

[0044] (3) The produc...

Embodiment 3

[0046] A preparation method of antimony-cerium modified molybdenum disulfide / indium oxide gas sensitive material includes the following steps:

[0047] (1) Hydrothermal synthesis of MoS 2 / In 2 O 3 Nanocomposite materials: 1) Dissolve 1mmol of sodium molybdate, 4mmol of thiourea, and 1mmol of citric acid in 30ml of water, and hydrothermally react at 180℃ for 24h to obtain MoS 2 , As In 2 O 3 Carrier; 2) 2mmolMoS 2 Carrier and 8mmol In 2 O 3 Mixing, the In 2 O 3 Nanoparticles dispersed into MoS 2 The surface of the lamella is obtained;

[0048] (2) In an argon protective atmosphere, use 0.05mmol of antimony trichloride and 0.05mmol of cerium nitrate as the source of antimony and cerium, respectively, and the MoS in step (1) 2 / In 2 O 3 Nanocomposite material mixing (the amount of antimony source and cerium source added is: Sb: Ce: In 2 O 3 The molar ratio of is 0.05:0.05:1), hydrothermally react at 200℃ for 20h, then centrifuge, dry the product, and set aside;

[0049] (3) The product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com