A kind of surface modification method of carbon/carbon composite material

A carbon composite material and surface modification technology, applied in the field of material surface modification, can solve the problems of shedding, low interface bonding strength, insufficient interface bonding strength, etc., and achieve the effects of enhancing cohesion, promoting chemical bonding, and improving interface bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) The carbon / carbon composite material was ultrasonically cleaned with acetone, absolute ethanol, and deionized water in sequence, and the sample obtained after drying was marked as A;

[0027] (2) disperse graphene oxide into water according to the concentration of 0.1g / L and stir evenly to obtain liquid B;

[0028] (3) Soak A completely in B for 24 hours, take it out and dry it to get C;

[0029] (4) Graphite powder and silicon powder are evenly mixed according to the mass ratio of 1:4, mixed with a planetary ball mill for 2 hours, and powder D is obtained after drying;

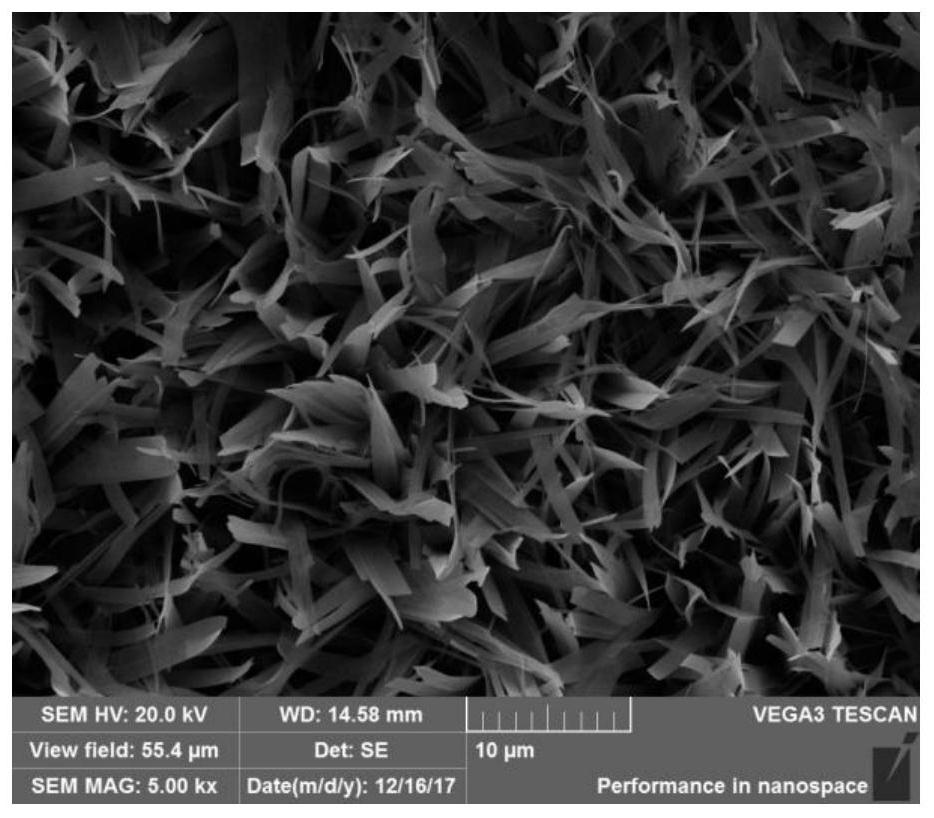

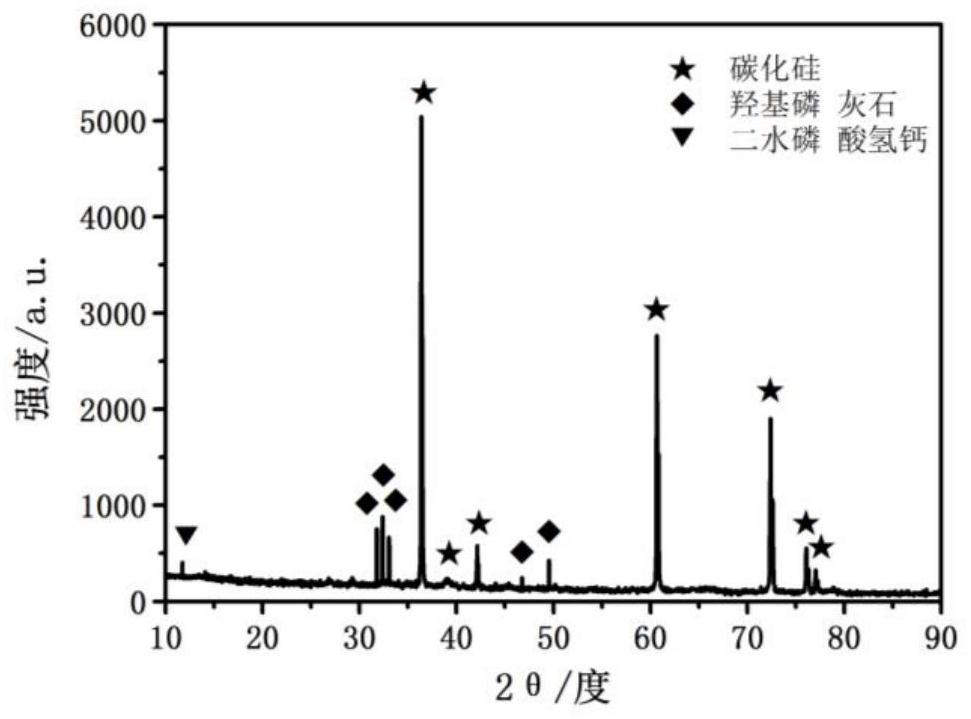

[0030] (5) Put C and powder D into a graphite crucible, wherein powder D completely wraps C, put the graphite crucible into a vacuum high-temperature furnace, heat up to 2000°C at a heating rate of 5°C after vacuuming, and keep it for 1 hour Naturally cool to room temperature, take out the sample, ultrasonically clean it with water and dry it, and the obtained sample is marked as E;

[0031] (6) ...

Embodiment 2

[0037] (1) The carbon / carbon composite material was ultrasonically cleaned with acetone, absolute ethanol, and deionized water in sequence, and the sample obtained after drying was marked as A;

[0038] (2) disperse graphene oxide into water according to the concentration of 0.3g / L and stir evenly to obtain liquid B;

[0039] (3) Soak A completely in B for 48 hours, take it out and dry it to get C;

[0040] (4) Graphite powder and silicon powder are uniformly mixed according to the mass ratio of 1:8, mixed with a planetary ball mill for 4 hours, and powder D is obtained after drying;

[0041] (5) Put C and powder D into a graphite crucible, wherein powder D completely wraps C, put the graphite crucible into a vacuum high-temperature furnace, heat up to 2200°C at a heating rate of 10°C after vacuuming, and keep it for 2 hours Naturally cool to room temperature, take out the sample, ultrasonically clean it with water and dry it, and the obtained sample is marked as E;

[0042]...

Embodiment 3

[0048] (1) The carbon / carbon composite material was ultrasonically cleaned with acetone, absolute ethanol, and deionized water in sequence, and the sample obtained after drying was marked as A;

[0049] (2) disperse graphene oxide into water according to the concentration of 0.2g / L and stir evenly to obtain liquid B;

[0050] (3) Soak A completely in B for 36 hours, take it out and dry it to get C;

[0051] (4) Graphite powder and silicon powder are uniformly mixed according to the mass ratio of 1:6, mixed with a planetary ball mill for 3 hours, and powder D is obtained after drying;

[0052] (5) Put C and powder D into a graphite crucible, wherein powder D completely wraps C, put the graphite crucible into a vacuum high-temperature furnace, heat up to 2100°C at a heating rate of 8°C after vacuuming, and keep warm for 1.5h After cooling down to room temperature naturally, take out the sample, ultrasonically clean it with water and dry it, and the obtained sample is marked as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com