High-affinity shrimp shell calcium powder, preparation method thereof and application of high-affinity shrimp shell calcium powder in preparation of medicine for treating calcium deficiency symptoms and/or diseases

A technology of shrimp shell calcium powder and affinity, applied in the field of medicine, can solve the problems of shrimp shell calcium hardness, limited addition, affecting application, etc., and achieves the effect of high calcium content and improved taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In a third aspect, the present invention provides a method for preparing high-affinity shrimp shell calcium powder with a core-shell structure, the method comprising: preparing a surface modifier into a surface modifier solution, and then treating the shrimp shell calcium powder with Boiling granulation to obtain the high-affinity shrimp shell calcium powder;

[0034] Wherein, the surface modifier is composed of maltodextrin, pregelatinized starch, konjac powder, sodium carboxymethylcellulose and xanthan gum.

[0035] Through the preparation method provided by the invention, the high-affinity shrimp shell calcium powder with a core-shell structure with the shrimp shell calcium powder as the core and a surface modifier as the shell can be obtained.

[0036] According to the present invention, the amount of the surface modifier can be changed within a wide range, in order to further improve the affinity of the high-affinity shrimp shell calcium powder to protein, starch, ...

Embodiment approach

[0048] According to a preferred embodiment of the present invention, the acid treatment method comprises: acid treatment of the shrimp shells in an acetic acid solution with a concentration of 0.1-0.5% by weight, wherein the solid-liquid ratio of the shrimp shells to the acetic acid solution is 1: 5-10.

[0049] According to the present invention, in order to further improve the quality of the prepared high-affinity shrimp shell calcium powder, preferably, the acid treatment is carried out under ultrasonic conditions.

[0050] Wherein, the conditions of the ultrasound can be changed in a wide range, preferably, the power of the ultrasound is 0.4-0.6 W / cm2 (for example, it can be 0.4 W / cm2, 0.45 W / cm2, 0.5 watts / square centimeter, 0.55 watts / square centimeter, 0.6 watts / square centimeter, wherein, the area is the bottom area of the container), and the ultrasonic time is 1-1.5 hours (for example, it can be 1 hour, 1.1 hours, 1.2 hours, 1.3 hours, 1.4 hours, 1.5 hours).

[00...

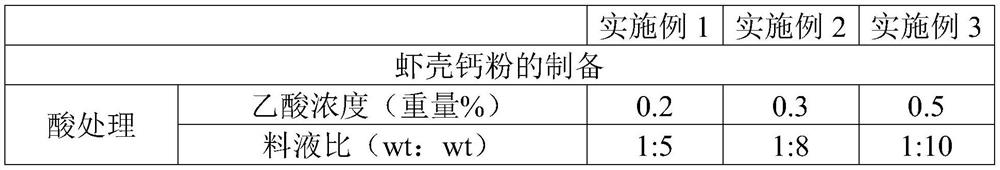

Embodiment 1-3

[0079] Used to illustrate the preparation method of high affinity calcium powder

[0080] According to the conditions shown in Table 1, the following operations were performed.

[0081] 1) Acid treatment: select the shell of fresh crayfish (ie, Procambarus clarkii) and perform ultrasonic treatment in an acetic acid solution.

[0082] 2) Drying and crushing: Drying the acid-treated shrimp shells with hot air, and then crushing them with a pulverizer to obtain coarse shrimp shell calcium powder.

[0083] 3) Softening: Mix the coarse shrimp shell calcium powder with water, and cook in a pressure cooker.

[0084] 4) Refinement: Add water to the softened material (using the softened material as the material, and the additional water as the liquid), use a colloid mill to pulverize, and then filter with a filter cloth, and take the filtrate and use a homogenizer to homogenize quality twice.

[0085] 5) Spray drying: the thinned material is dried in a spray drying tower, and then p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com