Device for preparing slow-release nitrogen fertilizer from modified zeolite and method for preparing slow-release nitrogen fertilizer by using same

A technology for modifying zeolite and nitrogen fertilizer, applied in fertilization equipment, nitrogen fertilizer, application and other directions, can solve the problems of limited ion adsorption performance, limited fertilizer industrialization development, and insufficient use of zeolite slow-release materials, etc., and achieve high ion exchange and adsorption. performance, reduced soil nutrient loss, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

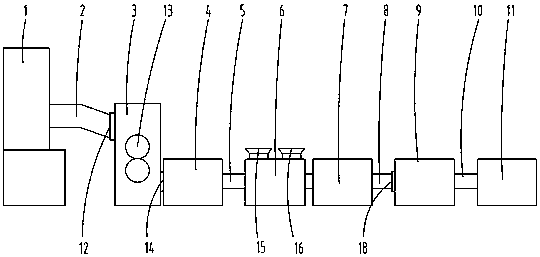

[0022] see figure 1 and 2 , a device for preparing slow-release nitrogen fertilizer based on natural zeolite, consisting of a pulverizer 1, a first conveyor belt 2, an adsorption reaction tank 3, a first dryer 4, a second conveyor belt 5, a disc granulator 6, and a second dryer 7. The third conveyor belt 8, the drum fluidized bed 9, the fourth conveyor belt 10, and the weighing bagging machine 11 are connected.

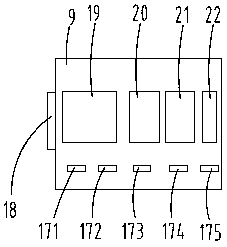

[0023] The upper end of the adsorption reaction pool 3 is provided with a reaction pool feed port 2 , the middle part is provided with stirring teeth 13 , and the lower end is provided with a reaction pool discharge port 14 . The upper part of the disc granulator 6 is equipped with a modified zeolite feed port 15 and a binder feed port 16 respectively. The drum fluidized bed 9 is provided with a first control switch 171, a second control switch 172, a third control switch 173, a fourth control switch 174 and a fifth control switch 175, and the first control switch 1...

Embodiment 2

[0026] Embodiment 2 Application of the device of the present invention in the preparation of zeolite-based slow-release nitrogen fertilizer

[0027] 1) Natural mordenite and clinoptilolite are mixed in a mass ratio of 1:1, mechanically pulverized by a pulverizer 1, passed through a 100-mesh sieve, and then enter the adsorption reaction pool 3 through the first conveyor belt 2, and the copper chloride solution with a mass fraction of 15% is passed through The reaction tank feed port 12 enters the adsorption reaction tank 3, the mass ratio of zeolite and copper chloride solution is 1:7-10, the mixed solution is stirred at room temperature by the stirring teeth 13 for 6 hours and then left to stand for 2 hours, repeating this process 3 times, removing After the supernatant, the zeolite precipitate is dried by the first dryer 4 to prepare metal chloride modified zeolite powder;

[0028] 2) Mix the above-mentioned modified zeolite powder with the granulation aid powder passed throu...

Embodiment 3

[0033] 1) Natural mordenite and clinoptilolite are mixed in a mass ratio of 1:1, mechanically pulverized by a pulverizer 1, passed through a 100-mesh sieve, and then enter the adsorption reaction pool 3 through the first conveyor belt 2, and the copper chloride solution with a mass fraction of 15% is passed through Feed inlet 12 enters adsorption reaction tank 3, the mass ratio of zeolite and copper chloride solution is 1:7, the mixed solution is left to stand for 2 hours after being stirred at room temperature by stirring teeth 13 for 6 hours, repeat this process 3 times, after removing the supernatant Drying the zeolite precipitate through the first dryer 4 to prepare metal chloride-modified zeolite powder;

[0034] 2) Mix the above-mentioned modified zeolite powder with the granulation aid powder passed through a 100-mesh sieve in a mass ratio of 85:15, and put them into the Carry out granulation in the disc granulator 6;

[0035] 3) After the above-mentioned granulated ze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com