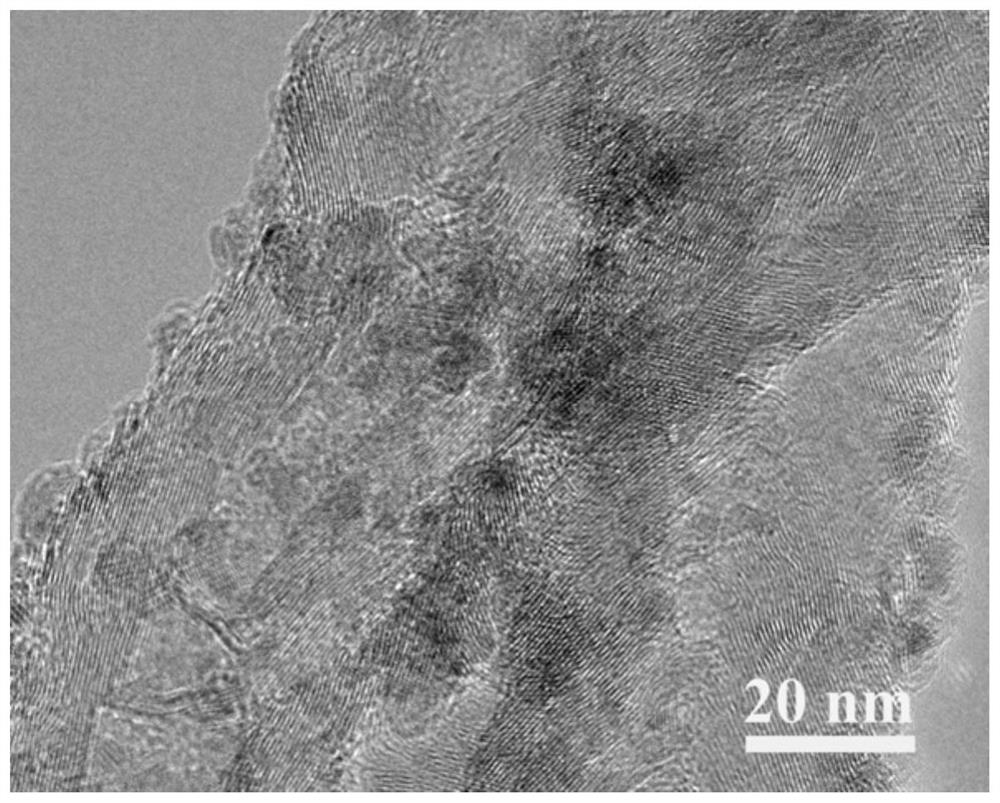

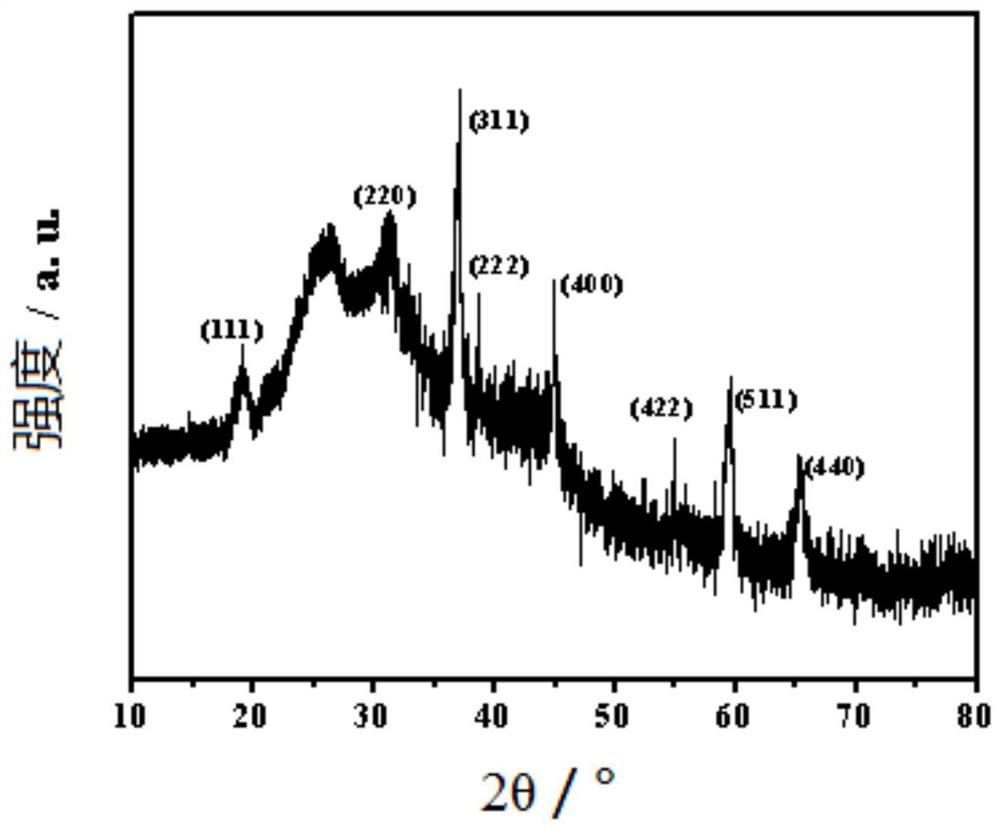

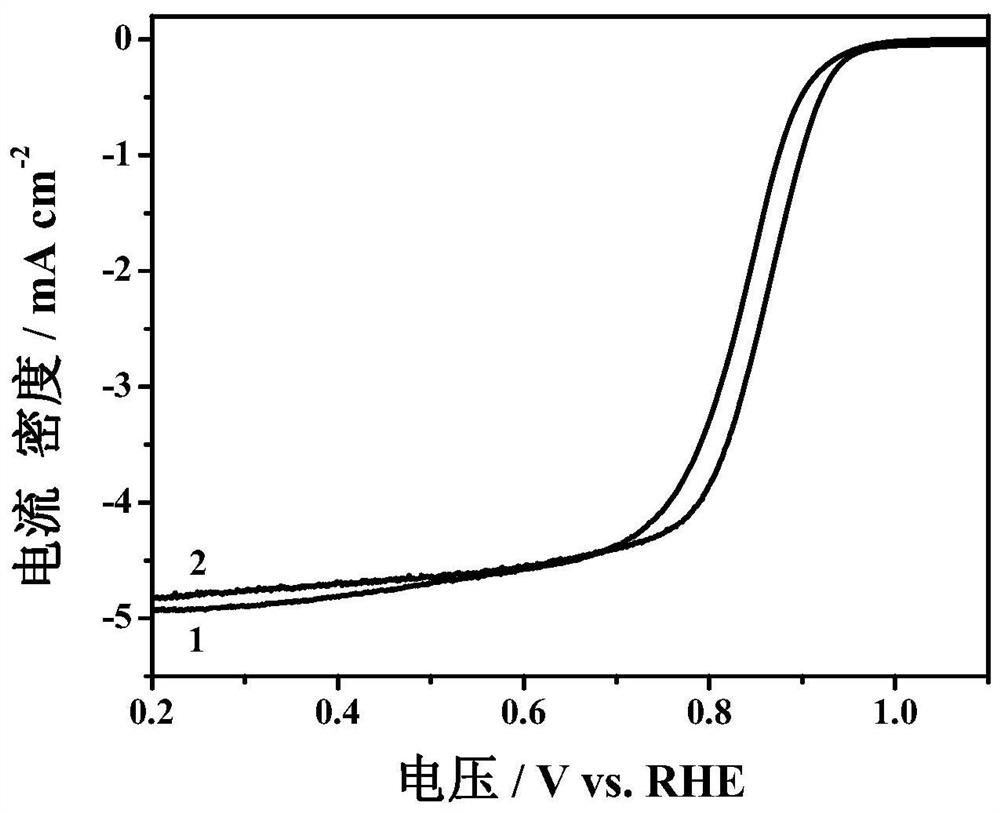

A kind of tricobalt tetroxide-amino carbon nanotube composite electrocatalytic material and its preparation and application

A technology of amino carbon nanotubes and cobalt tetroxide, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of incomparable catalytic performance, achieve excellent catalytic performance, improve electrical conductivity and Effects of specific surface area and electrochemical stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Weigh 140 mg of carbon nanotubes and put them in 100 mL of concentrated sulfuric acid and concentrated nitric acid mixed acid with a volume ratio of 1:3. After 300 W ultrasonic dispersion for 2 hours, wash and centrifuge with deionized water for 5 times, then dry in an oven at 70 ° C to obtain carbon dioxide nanotube.

[0033] (2) Add 60 mg of oxidized carbon nanotubes, 192 mg of sodium hyponitrate and 5 mL of ethylenediamine into 50 mL of dimethylacetamide for mixing, put them into an electric constant temperature blast drying oven and heat to 120° C. and keep the temperature for reaction for 12 hours. Then cool to room temperature, filter and wash with deionized water for 3 times, and then dry in an oven at 60° C. to obtain amino carbon nanotubes.

[0034] (3) Add 15 mg of amino carbon nanotubes and 20 mg of cobalt acetate hexahydrate to 50 mL of a mixture of dimethylformamide and ethanol (volume ratio 8:2), heat at 80°C and stir for 1 hour, add 0.5 mL of ammonia ...

Embodiment 2

[0043] (1) Weigh 140 mg of carbon nanotubes and put them in 100 mL of concentrated sulfuric acid and concentrated nitric acid mixed acid with a volume ratio of 1:5. After 5 hours of ultrasonic dispersion at 300 W, wash and centrifuge with deionized water for 7 times, and then dry in an oven at 80 ° C to obtain carbon dioxide nanotube.

[0044] (2) Add 120 mg of oxidized carbon nanotubes, 240 mg of sodium hyponitrate and 10 mL of ethylenediamine into 50 mL of dimethylacetamide for mixing, put them into an electric constant temperature blast drying oven and heat to 150° C. and keep the temperature for reaction for 12 hours. Then cool to room temperature, filter and wash with deionized water for 5 times, and then dry in an oven at 80° C. to obtain amino carbon nanotubes.

[0045] (3) Add 30 mg of aminocarbon nanotubes and 50 mg of cobalt acetate hexahydrate to 50 mL of a mixed solution of dimethylformamide and ethanol (volume ratio 8:2), heat at 100° C. and stir for 2 hours, add ...

Embodiment 3

[0049] (1) Weigh 140mg of carbon nanotubes and place them in 100mL of concentrated sulfuric acid and concentrated nitric acid mixed acid with a volume ratio of 1:1. After 300W ultrasonic dispersion for 2 hours, wash and centrifuge with deionized water for 6 times, then dry in an oven at 70°C to obtain oxidized carbon nanotubes. carbon nanotubes.

[0050] (2) Add 100 mg of oxidized carbon nanotubes, 234 mg of sodium hyponitrate and 8 mL of triethylenetetramine into 50 mL of dimethylacetamide for mixing, put them in an electric constant temperature blast drying oven and heat to 140 ° C and keep warm for 11 hour, then cooled to room temperature, filtered and washed with deionized water for 4 times, and then dried in an oven at 70°C to obtain amino carbon nanotubes.

[0051] (3) Add 20 mg of aminocarbon nanotubes and 200 mg of cobalt acetate hexahydrate to 50 mL of a mixture of dimethylformamide and ethanol (volume ratio 8:2), heat at 80° C. and stir for 1 hour, add 2 mL of ammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com