One-step method for preparing manganese ion sieve precursor lixmn3-xo4

A technology of ion sieve and precursor, applied in the field of energy-saving production of inorganic compounds, can solve the problems of no process simplification, good adsorption effect, complicated preparation process, low degree of industrialization, etc., and achieve low cost, abundant sources, and few by-products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

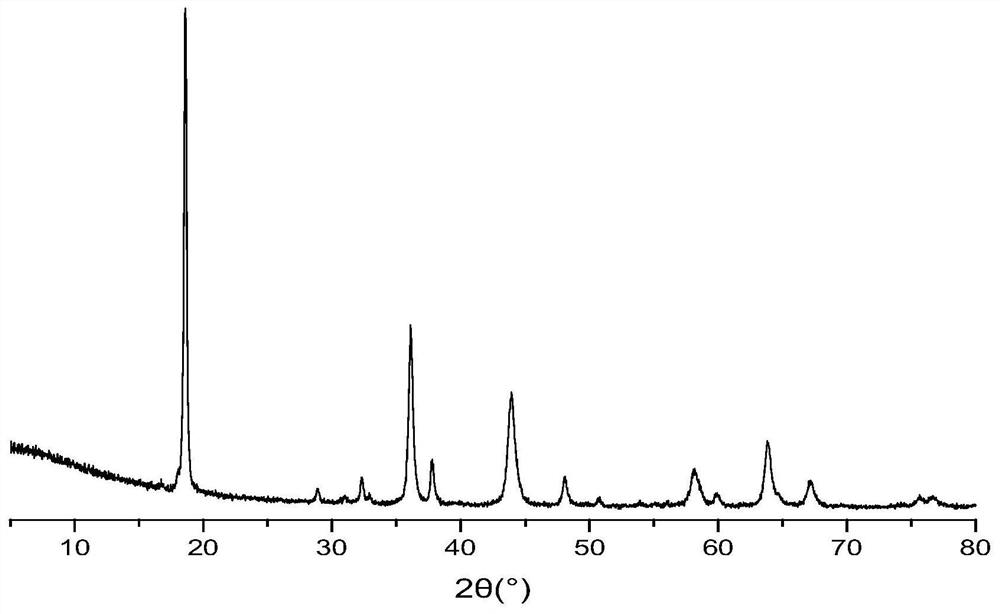

[0034]The preparation process of the present invention is as follows: mix manganese salt, liquid-phase inorganic / organic oxidizing agent and lithium-containing inorganic powder, put the mixture in a mechanically sealed high-speed grinding device for mechanical grinding for 1-4 hours, and make it generate a one-step solid phase reaction to obtain a mixture; wherein, the manganese salt powder raw materials include but not limited to various industrial grade, analytical pure or battery grade manganese chloride, manganese nitrate and other salt raw materials, and the particle size of the manganese salt powder is below 500 μm; lithium-containing inorganic The powder is one or more of lithium hydroxide and lithium carbonate. The particle size of the lithium-containing inorganic powder is less than 500 μm; the ratio of the amount of lithium to the amount of manganese is 1 to 0.5:1; liquid-phase oxidants include but are not limited to hydrogen peroxide, peracetic acid or peroxybenzoic ...

Embodiment 1

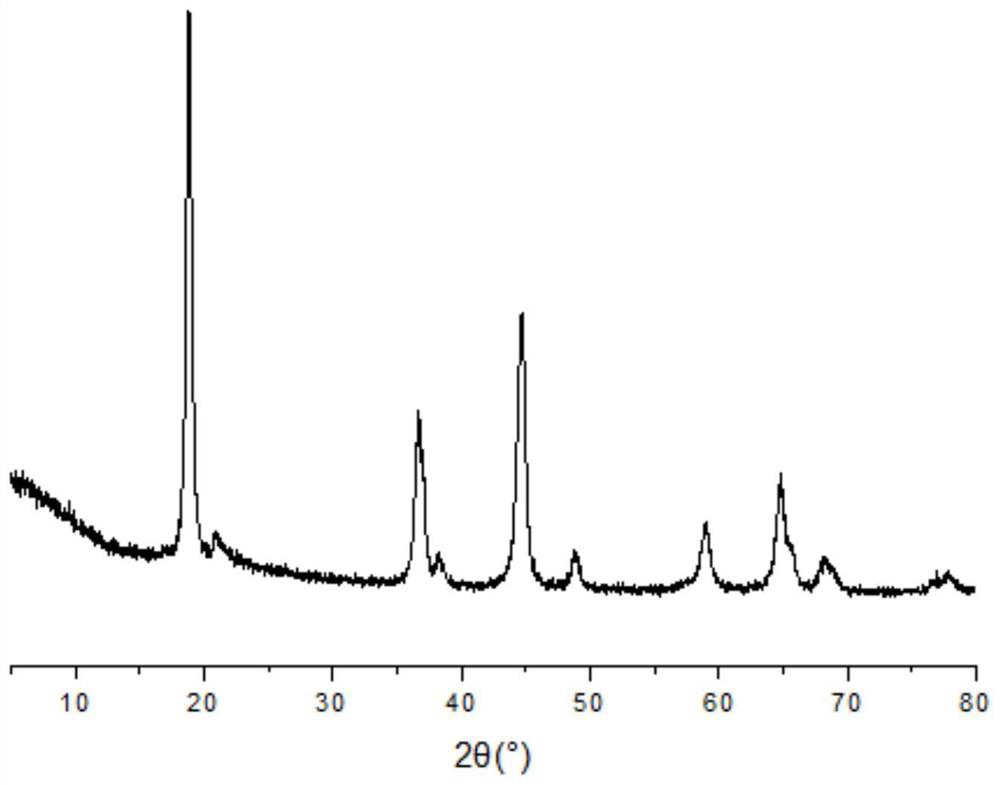

[0039] Accurately weigh 200g of manganese nitrate tetrahydrate and 42g of lithium hydroxide monohydrate and mix them thoroughly, add 300mL of 30% hydrogen peroxide, place it in an eccentric vibrating mill, set the speed at 1500r / min, repeat the grinding cycle for 4h, solidification occurs After the phase reaction, dry and evaporate the obtained slurry at 70°C to remove organic by-products and water to obtain the lithium manganese oxide intermediate, and react the lithium manganese oxide intermediate at 550°C for 6h in an aerobic environment , you can get manganese oxide lithium ion sieve precursor Li 1.6 mn 1.6 o 4 . Precursor Li 1.6 mn 1.6 o 4 Delithium treatment in 0.5M hydrochloric acid, take 1g for Li + In the aqueous phase solution with a concentration of 220mg / L, it was adsorbed at pH=8 for 6h, and the adsorption amount of lithium was measured to be 23.8mg / g. The saturated lithium ion sieve was placed in 0.5M hydrochloric acid solution for analysis, and the analys...

Embodiment 2

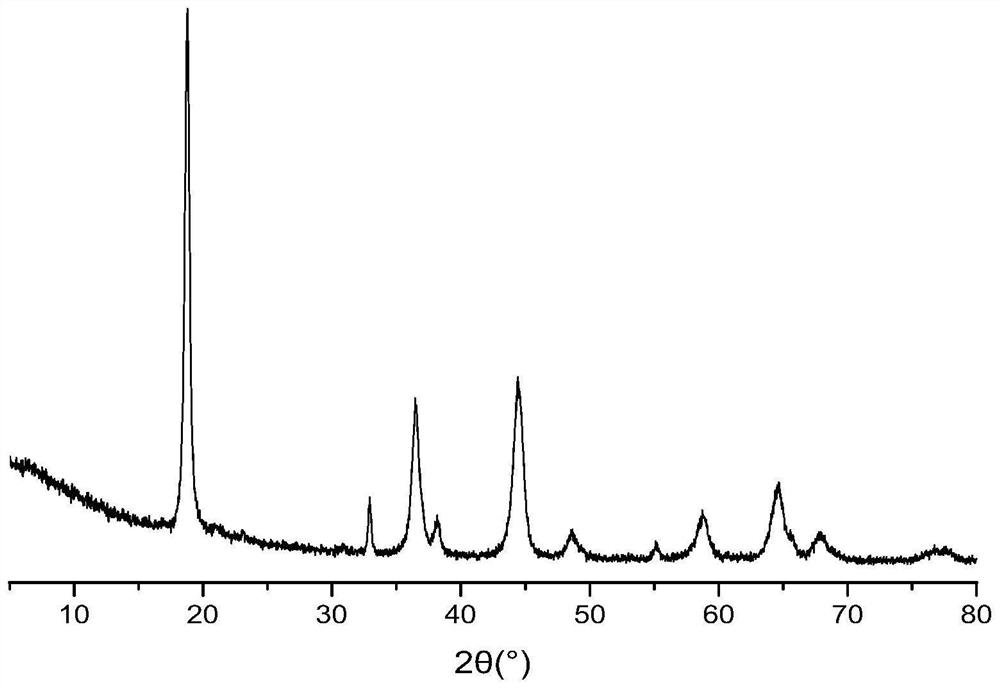

[0043] Accurately weigh 200g of manganese nitrate tetrahydrate, 300mL of 30% hydrogen peroxide, 100mL of peroxybenzoic acid and 42g of lithium hydroxide monohydrate and fully mix them in the eccentric vibrating mill. After the phase reaction, the obtained slurry was dried and evaporated at 70°C to remove organic by-products and water to obtain a lithium manganese oxide intermediate, and the lithium manganese oxide intermediate was reacted at 500°C for 6h in an aerobic environment , you can get manganese oxide lithium ion sieve precursor LiMn with a particle size distribution range of 50-1000nm 2 o 4 . The precursor LiMn 2 o 4 Delithium treatment in 0.5M hydrochloric acid, take 1g for Li + In an aqueous phase solution with a concentration of 220 mg / L, it was adsorbed at pH=8 for 4 hours, and the adsorption amount of lithium was measured to be 21.3 mg / g. The saturated lithium ion sieve was placed in 0.5M hydrochloric acid solution for analysis, and the analysis rate reached...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com