A kind of preparation method of the additive of water-soluble core

A water-soluble core and additive technology, used in cores, casting equipment, metal processing equipment, etc., can solve the problems of low core strength, short service life, easy corrosion of nozzles, etc., to achieve strong wetting performance and improve strength. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

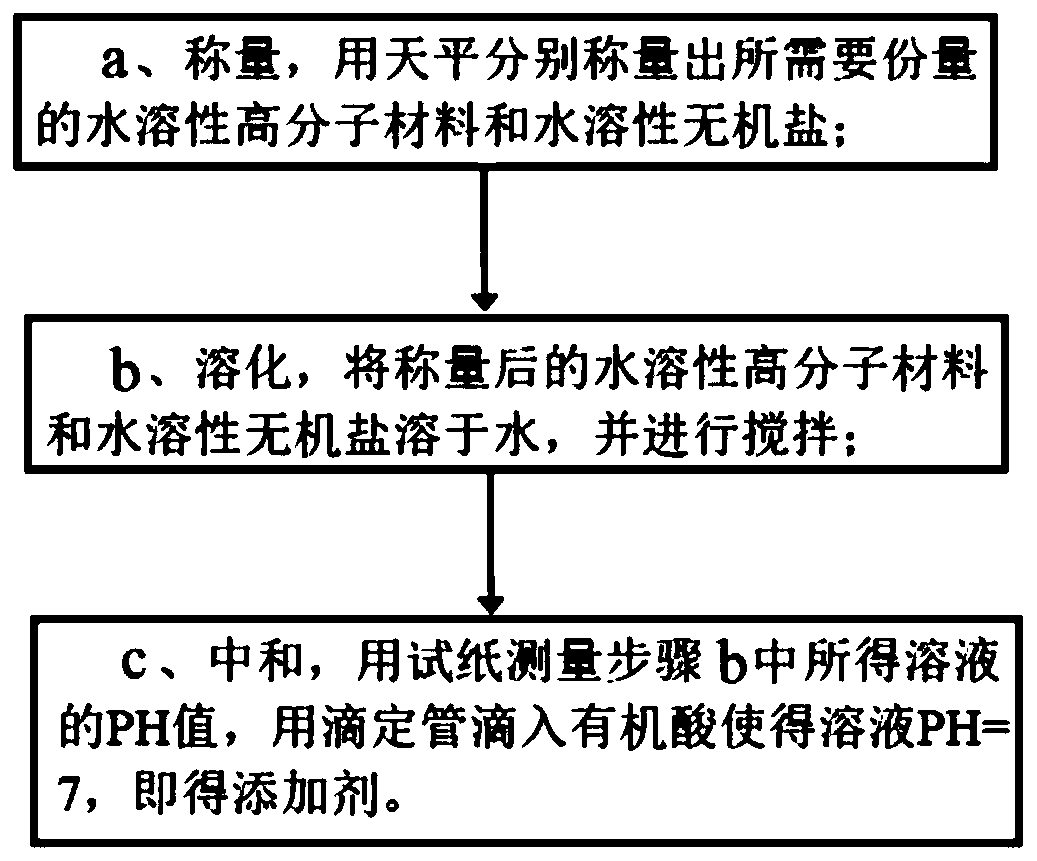

[0044]A method for preparing an additive for a water-soluble core in this embodiment, the additive includes the following components: 10%-20wt% of water-soluble polymer material, 0-5wt% of organic acid, 75-90wt% of water-soluble inorganic salt; The polymer material is one or more of starch, cellulose, polyethylene glycol, epoxy resin, polyacrylamide, etc.; the organic acid is one or more of acetic acid, citric acid, oxalic acid, and sulfonic acid; The water-soluble inorganic salt is one or more of chloride, bromide, carbonate, sulfate, phosphate, nitrate, metaaluminate and hydroxide. The water-soluble polymer material plays the role of ensuring the low-temperature bonding strength, the water-soluble inorganic salt is the main binder, which ensures the core strength at medium and high temperatures, and the organic acid plays the role of adjusting the pH value. Since the additive and water are mixed into a solution, the water gradually evaporates during the subsequent heating pr...

Embodiment 2

[0066] A kind of high-strength water-soluble core of the present embodiment, the production process is as follows:

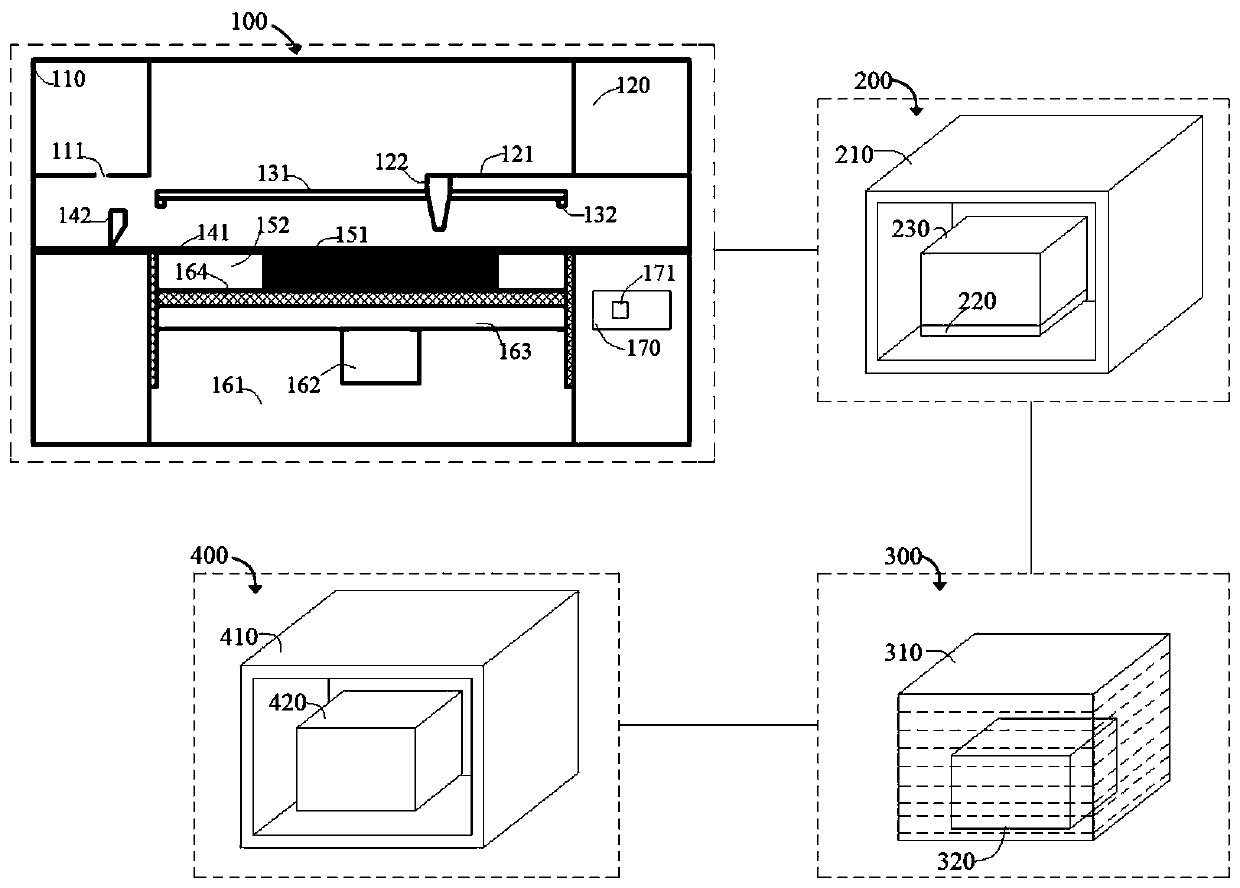

[0067] S100, micro-droplet injection molding, lay 100 / 140 mesh silica sand on the lifting table 163, the liquid spraying device 122 sprays additives according to the droplet path generated by the solid model of the core, after the micro-droplet spraying on this level is completed, the lifting work The stage 163 goes down by 0.1mm, and completes the subsequent dripping processes on discrete levels in sequence until the dripping processes on all discrete levels are completed;

[0068] S200, intermittent microwave curing, take out the injection-molded core together with the powder bed 164, place it in the microwave oven 210 for intermittent microwave heating, and take it out after the core is completely cured;

[0069] S300, spraying inorganic salt solution, taking out the mold core after microwave curing, spraying Na + / / Cl - , CO 3 2- -H 2 For the solution o...

Embodiment 3

[0074] A kind of high-strength water-soluble core of the present embodiment, the production process is as follows:

[0075] S100, micro-droplet injection molding, mix 70 / 100 mesh silica sand and 100 / 140 mesh magnesia sand evenly in a ratio of 7:3 and spread them on the lifting workbench 163, and the liquid spraying device 122 generates according to the solid model of the core Additives are sprayed on the dripping path. After the spraying of micro-droplets on this level is completed, the lifting table 163 moves down by 0.2mm, and the subsequent dripping processes on discrete levels are completed in sequence until the dripping processes on all discrete levels are completed;

[0076] S200, intermittent microwave curing, take out the injection-molded core together with the powder bed 164, place it in the microwave oven 210 for intermittent microwave heating, and take it out after the core is completely cured;

[0077] S300, infiltrate the inorganic salt solution, take out the mold c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com